You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

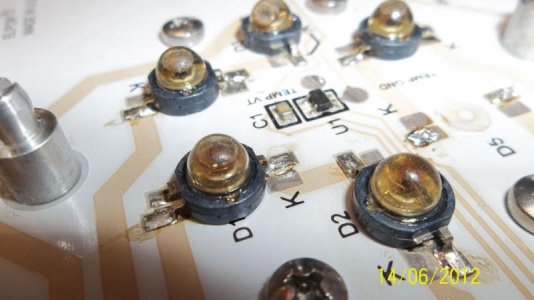

Anyone using Violet LEDs - Burning Optics

- Thread starter zachts

- Start date

Mine are from rapid they run 10 hours a day

how long have you had the violets running and are they enclosed by a splash gaurd or free air. all mine have the wireing and optics side of the heatsinks sealed up by the splash gaurds. thanks

Hi Guys,

I came across this post a while back and just found this issue with burned led's (these do not have a lens), these are at a wavelength of 430-490 (blue).

The problem was first found when it was noticed that they led's were not delivering enough light and when it was measured it was at 17 μW"¢cm-2"¢nm-1

while it should have been around 70.

I have removed one and noticed that there is not much heat sink compound on the pad/led and to me looks like it overheated but right now. Also the soldering job they did on this module is really poor and looks like someone was practicing.

I came across this post a while back and just found this issue with burned led's (these do not have a lens), these are at a wavelength of 430-490 (blue).

The problem was first found when it was noticed that they led's were not delivering enough light and when it was measured it was at 17 μW"¢cm-2"¢nm-1

while it should have been around 70.

I have removed one and noticed that there is not much heat sink compound on the pad/led and to me looks like it overheated but right now. Also the soldering job they did on this module is really poor and looks like someone was practicing.

Attachments

Rosscopeco

New member

I had the maxspect units do the same thing with the RBs and UVs. I have posted pictures in the maxspect thread and many have had he same issue.

My guess is an issue with thermal runaway causing the LEDs to cook. Each LED will behave slightly diferently and the problem compounds the hotter they get.

When over driven a LED can burn a hole through an acrylic shield and start a book smouldering. True story.

I'm pretty keen to see how my new build holds up after reading this post. There seems to be a need for better balancing with multiple leds.

My guess is an issue with thermal runaway causing the LEDs to cook. Each LED will behave slightly diferently and the problem compounds the hotter they get.

When over driven a LED can burn a hole through an acrylic shield and start a book smouldering. True story.

I'm pretty keen to see how my new build holds up after reading this post. There seems to be a need for better balancing with multiple leds.

Thanks for posting Rosscopeco.

For anyone just finding this tread the issue I'm having and that is pictured at the start of the tread has to do only with the violet LEDs. all 12 leds on this fixture, 3CW, 3RB, 3 violet, 1red, 1cyan, 1WW, are all running on the same string at aproximately 600ma. they are attached to a very beefy heatsink via arctic silver thermal paste and screws and the heatsink is fan cooled and never even gets warm to the touch.

Only my violets are burning as in the picture, and not only on this fixture but on all of mine. the longest running fixture was put into use in January 2012 so this problem is occuring very quickly. the fixture pictured above has only been running since the end of February.

I'm hoping this thread will gather enough info from people to shed some light on why some people have this issue and some don't. It would be helpful if you have used violet LEDs to post you results and the specs of your setup. Pictures are good to

Thanks

For anyone just finding this tread the issue I'm having and that is pictured at the start of the tread has to do only with the violet LEDs. all 12 leds on this fixture, 3CW, 3RB, 3 violet, 1red, 1cyan, 1WW, are all running on the same string at aproximately 600ma. they are attached to a very beefy heatsink via arctic silver thermal paste and screws and the heatsink is fan cooled and never even gets warm to the touch.

Only my violets are burning as in the picture, and not only on this fixture but on all of mine. the longest running fixture was put into use in January 2012 so this problem is occuring very quickly. the fixture pictured above has only been running since the end of February.

I'm hoping this thread will gather enough info from people to shed some light on why some people have this issue and some don't. It would be helpful if you have used violet LEDs to post you results and the specs of your setup. Pictures are good to

Thanks

led side of the fixture is enclosed by a splach gaurd/difusing lens. you can see the cover in place in the picture of the fixture over my tank. I'ts not air tight but close enough. I've never read anywhere yet about the lenses needing to be cooled? and it's only the violets that burned.

kcress

New member

I've never read anywhere yet about the lenses needing to be cooled?

Ahhh You haven't read where I explained how the biggest age related assault on lumen maintenance is the thermal aging of the LED domes.. The hotter the LED lenses the faster the output decays.

I would suspect that if you actually moved air across the fronts of your LEDs you would have no more issues with melting lenses.

Ahhh You haven't read where I explained how the biggest age related assault on lumen maintenance is the thermal aging of the LED domes.. The hotter the LED lenses the faster the output decays.:

I would suspect that if you actually moved air across the fronts of your LEDs you would have no more issues with melting lenses.

thanks for the info. I'll have to do some more research on this. I think there is still some other factor at work though as the other LEDs in my arrays are just fine. the Violets are all from reputable sources, some of the blues and whites are from Ebay and noticibly lower quality.

Kcress do you have any examples of fixtures youve designed using violets that have been up and running for some time? I'm hoping people will start posting results and designs here for comparison.

kcress

New member

Kcress do you have any examples of fixtures youve designed using violets that have been up and running for some time?

I haven't gotten around to using violets yet so I don't have any examples for you. Sorry.

Tickle

New member

Yeah but look at the pictures I posted this damage is the built in plastic optic of the LEDs straight from the manufacurture. when I snapped the burnt brown plastic dome off the work are good as new......

I'm hearing mixed reports of some people experiencing simmilar results and others not having this happen. and I' seeing the same thing on Violets from RapidLED and Aquastyle, all Bridgelux LEDs. So, I'm trying to determine if its and inherint flaw inthe manufacure of all violet LEDs or just a fluke that I got bad ones from three different sources. You would think that the plastics used in the LED themselves would be UV stable, right? Evidently not, but that doesn't explain why some report no problems when running at near 700ma currents. Mine are only running at 600ma.

They should be to a point but like stated before if the secondary lens is cooked and not allowing the UV rays to pass through but rather is bouncing them back then that would surpass the amount of light that the primary lens is intended.

Make sense?

Sent from my SCH-I500 using Tapatalk 2

Last edited by a moderator:

It looks to me like those whites are burning up - not the phosphor but the blue chip underneath.. It shouldn't be turning black at only ~6 months old. Between those LEDs and the star, are they soldered on (the copper slug under the LED chip itself) or was thermal paste used? I have seen some of these chinese stars where the LED was not sitting flat on the star, and with thermal grease there is not much conductivity in such a situation.. With solder the situation is not great but massively better than with paste.

These LEDs were made to run in situations like replacement light bulbs, don't know if you guys have used any of those but they get HOT. Our cooling setups keep the chips far cooler than they were designed to run, unless there's some sort of problem.

420nm may be near UV, actual UV output should be pretty minimal.. and in fact some 440nm LEDs will have some output at 420nm still.

These LEDs were made to run in situations like replacement light bulbs, don't know if you guys have used any of those but they get HOT. Our cooling setups keep the chips far cooler than they were designed to run, unless there's some sort of problem.

420nm may be near UV, actual UV output should be pretty minimal.. and in fact some 440nm LEDs will have some output at 420nm still.

Last edited:

If the violet LEDs have lower efficiency than the whites, they will get hotter even though they are being driven at the same power and could burn while the others wouldn't. I don't know the specs on the different LEDs you are using but it could be something to consider.

I also want to reinforce what was stated before about the use of thermal compound, only a very thin layer should be between the star and the heat sink to compensate for imperfections between the two surfaces. When I build lights, I smear a thin film of a layer onto the back the star with my finger (wrapped with sandwich bag plastic or saran wrap) then when I put the star on the heat sink there is no squeeze out. Just because your heat sink is staying cool doesn't mean it's doing its job. If the heat isn't making it to the heat sink to begin with then your LEDs could still overheat. Try and feel the temperature of the underside of the heat sink and slowly move closer to the star (don't burn yourself) after the light has been running for a while. It should gradually feel hotter but I wouldn't think the star should feel significantly hotter than the adjacent heat sink if it is doing its job properly.

I also want to reinforce what was stated before about the use of thermal compound, only a very thin layer should be between the star and the heat sink to compensate for imperfections between the two surfaces. When I build lights, I smear a thin film of a layer onto the back the star with my finger (wrapped with sandwich bag plastic or saran wrap) then when I put the star on the heat sink there is no squeeze out. Just because your heat sink is staying cool doesn't mean it's doing its job. If the heat isn't making it to the heat sink to begin with then your LEDs could still overheat. Try and feel the temperature of the underside of the heat sink and slowly move closer to the star (don't burn yourself) after the light has been running for a while. It should gradually feel hotter but I wouldn't think the star should feel significantly hotter than the adjacent heat sink if it is doing its job properly.

one clownfish

Member

After 6 months of use, I'm have the same problem zachts is having. I know for sure my leds are staying cool. After running the violets all day, I can hold my finger on the lens for 15 seconds before I have to move it. I broke off some of the lenses and the leds still looked good. I'm going to pop off all the lenses and put some other ones on.

Last edited by a moderator:

After 6 months of use, I'm have the same problem zachts is having. I know for sure my leds are staying cool. After running the violets all day, I can hold my finger on the lens for 15 seconds before I have to move it. I broke off some of the lenses and the leds still looked good. I'm going to pop off all the lenses and put some other ones on.

I don't think the lens is the important part to measure; it would be the star the emitter is mounted that is critical.

Last edited by a moderator:

one clownfish

Member

I don't think the lens is the important part to measure; it would be the star the emitter is mounted that is critical.

That isn't the problem either. All of my Leds are mounted on a large heat sink. The whole fixture never gets hot to the touch. I can't remember the exact temp of the heat sink behind the star before I hung it but it wasnt much. I can put my fingers anywhere around the leds without getting burned. I think the lenses they use for the violet leds are defective.

mcgyvr

New member

Outgassing of thermal greases/glues,etc.. and other VOC's get trapped in the surface of the lens.. The shorter and stronger wavelength of the violet LED's causes those VOC's to quickly discolor.

This does not happen with the longer/weaker wavelengths of other colors further from the violet/blue.

This does not happen with the longer/weaker wavelengths of other colors further from the violet/blue.

Lots of good info here. thanks all! After much tinkering and testing this summer I've come to the conclusion that not all violets are created equal even if they supposedly use the same chip. shoddy construction of the led to the star and/or poor quality materials in the plasics in the lens are the two main problems.

poor quality plastics seem to be the issue on mine. I don't know if it's the extra heat produced and radiated forward towards the lens by the less efficient violet LEDs or if it has something to do with the near UV spectrum and photo degredation of the plasic. but in either case the problem is unique to the violet LEDs. As only those turned the plastic domes brown and bubbly. I ran LEDs with the same lenses by the same manufactures in different colors and only the violets had issues. Not sure what that's worth but there it is.

Now it seems that violets are catching up to CREE and using the same little silicon lens that CREE's been using. Hopefuly that solves the issue. now if only you could get a violet that could put out 1600mw at 3volts and 1000ma and keep pace with the royal blues that are out there........

poor quality plastics seem to be the issue on mine. I don't know if it's the extra heat produced and radiated forward towards the lens by the less efficient violet LEDs or if it has something to do with the near UV spectrum and photo degredation of the plasic. but in either case the problem is unique to the violet LEDs. As only those turned the plastic domes brown and bubbly. I ran LEDs with the same lenses by the same manufactures in different colors and only the violets had issues. Not sure what that's worth but there it is.

Now it seems that violets are catching up to CREE and using the same little silicon lens that CREE's been using. Hopefuly that solves the issue. now if only you could get a violet that could put out 1600mw at 3volts and 1000ma and keep pace with the royal blues that are out there........

Similar threads

- Replies

- 0

- Views

- 79

- Replies

- 11

- Views

- 701

- Replies

- 5

- Views

- 589

- Replies

- 8

- Views

- 631