It's a bit frustrating when I post a suggestion and someone (in this case Wazzel) says NOPE, might as well said hey dummy you don't know what you're talking about. I'm not going to respond to more of his posts. I will try to respond to yours, so you have a little more information or another point of view.

This link is a bit deep, but, does a pretty good job of explaining the dynamics of multiple different water pump technology.

http://www.pumped101.com/efficiency.pdf

Take note that it's very general, but, the pumps used in our tanks are not FREQ drive (VHD), meaning that their RPM is derived from utility power 60hz, the impeller design is usually optimized at about 6' some less some more. So, when you use a ball valve it artificially increases head pressure (often beyond optimal design), and therefore reduces the pump life and will ALWAYS use more energy.

I will agree there may be some pump manufacturers that do a poor job of QC and would allow a free-flowing pump to overspend causing damage, but, I would hope this would be the exception not the rule.

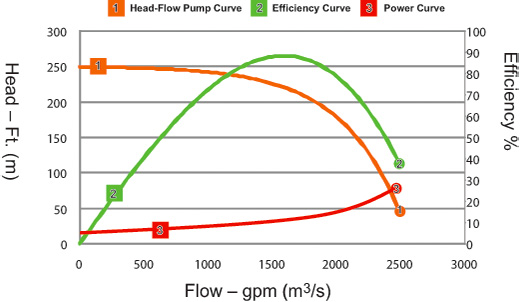

If you reference the article or most any pump manufacturer's flow graph, you will see a sweet spot (peak efficiency). Again in aquariums, this I have found to be about 4-6 ' where there is some loss of flow, but, substantially less than 50%. This matches the typical PEAK EFFICIENCY of a pumps design. So.... If you need 60 or 70% of the capacity of the pump to meet your needs, and you add a ball valve, you push the envelope of low efficiency. Much like any machine, they are designed to run at a higher capacity than required, but, they use more energy, create more heat and therefore don't last as long.

The above said, the opposite is true, if the design is for 4-6 ' and you run it at 1' flow will be maxed out with LESS actual work being done and a different pump would be a better choice. Damage, maybe on cheap bearings, irregular windings, things of generally poor quality equipment.

So... Look at our user Mag 700, let's assume 5' HP

https://www.google.com/search?q=mag...aquarium+pump+700+curve&imgrc=QkJFJWhYJPFKzM:

He has max about 400gph, which means 100% capacity, if you reference the 1st link, you will see efficiency is the worst at this rate, so why restrict it to 300gph and hold that bottom of the curve, relieve the pressure back to the sump, move left of the power curve, draw less wattage, make less heat and get the same results.

Now... If his goal was 100gph, you would already be to the left of the EFFICIENCY curve and additional pressure may (I still have trouble with this, because it has to ASSUME bad quality parts) allow the pump to last longer. Now even with a concession of it lasting longer, it will still (likely based on constant speed which is known and impeller design which is unknown) take more ENERGY (watt hours) to push 200gph than 100gph to 5'. It may be very minor, but, I promise unless the impeller has SEVERE cavitation the energy will be more.

Hope this helps get a different scientific explanation on why a simple restrictor on a semi-reasonably sized pump, is not better than a relief.

Sent from my iPad using Tapatalk