Zachts, is your aluminum c channel sufficient at keeping your vero 10 chips at an acceptable temp? Also what size is your fixture, and what size tank is it for? What amperage are you running your vero 10s? Sorry so many questions but i am not finding many threads to read with people using these stars and giving information on their setup. Thanks in advance.

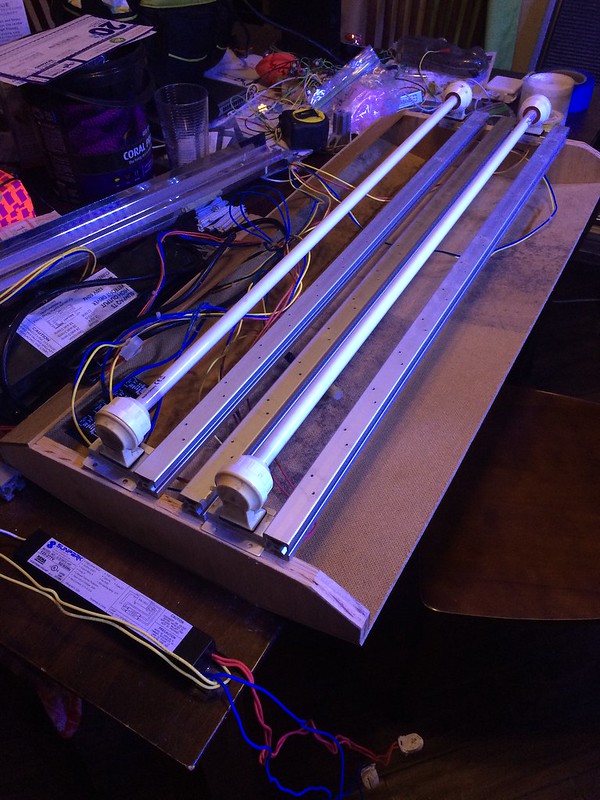

1" c channel they are around 16" long. fixture measures roughly 7"W x 20"L x 4"H. There's two fans in the center that vent out the top on the ends. Very good airflow in, around, and between each piece of C channel, but the fans don't have to work all that hard to keep things under 100 degrees.

The Vero's are only running something around 250-300mA when on at 100% duty cycle (I'd have to go check but if I recall right they are only running 50% duty cycle so not putting out much heat at all). I wired the two in parallel with a current mirror of the original white driver that had been running a pair of 3up white star chips in series. I don't have a temp sensor directly behind them but from other testing they should be fine. (I'm only monitoring temp on the "actinic" strips as they have the highest total heat load on them and are furthest from the fans and receive less air flow than the center clusters.)

I'ts over my frag tank, a standard 55 gallon, and lights one half, more than enough to grow SPS on the racks and softies on the bottom. Nothing is running over ~600mA so not even full power that it would be capable of. I't draws just under 90watts with everything on full power.

More pics on my profile and I have a build thread floating around here somewhere, but haven't updated it in a while with the changes pictured earlier.