reefermad619

New member

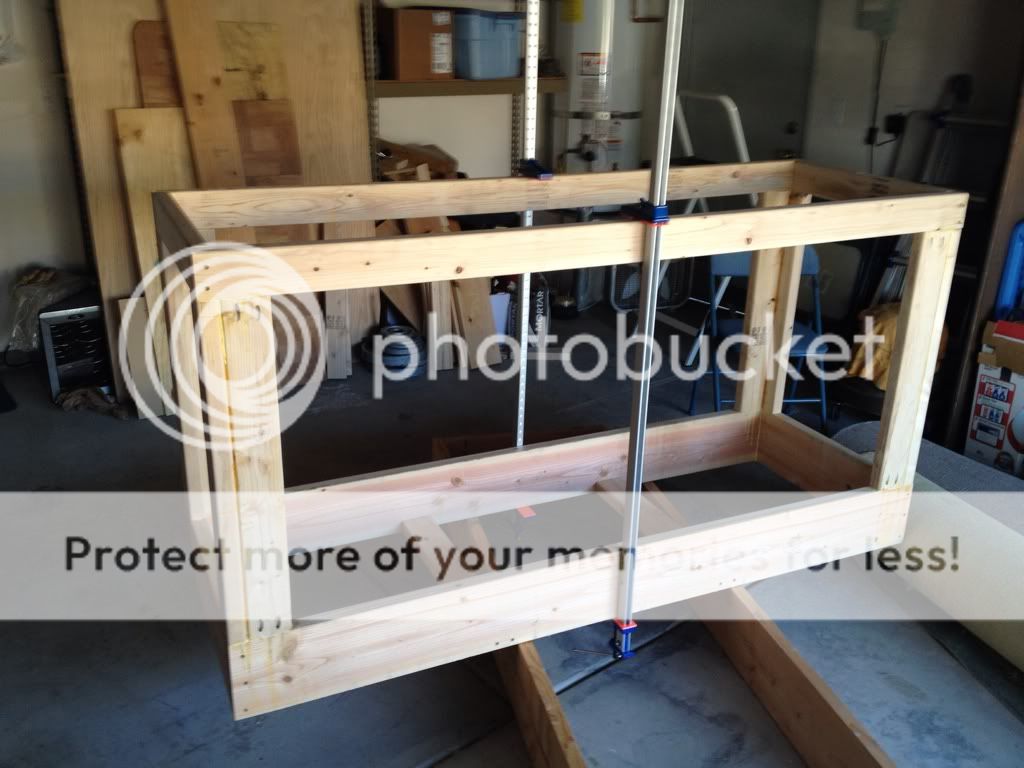

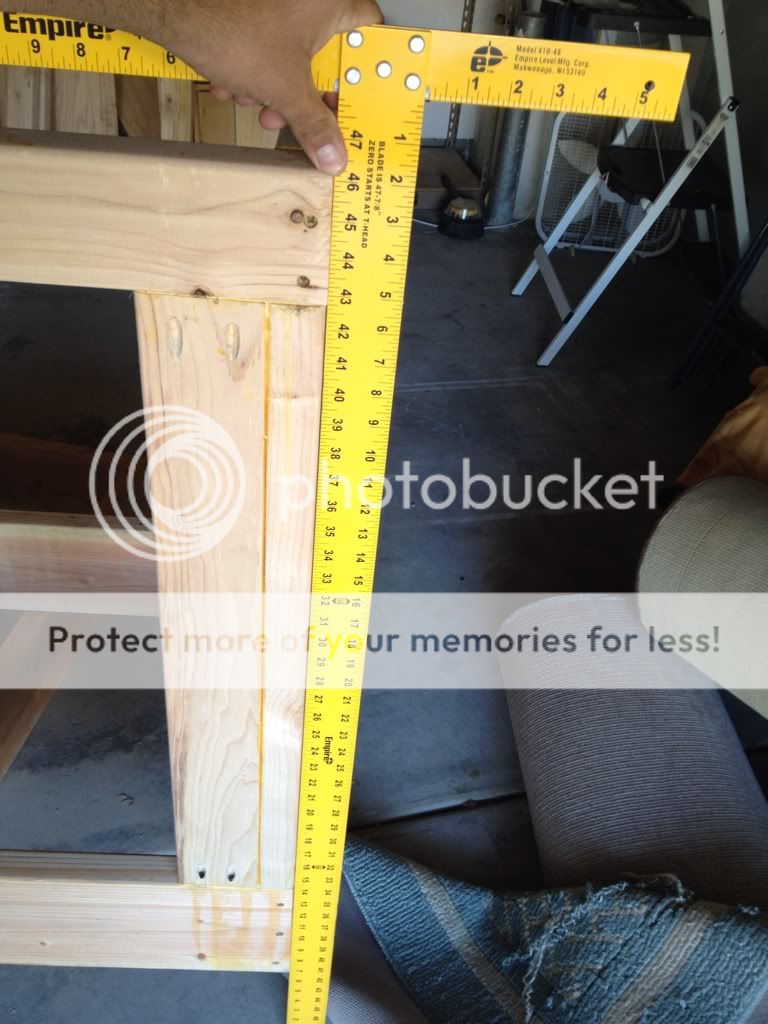

So, I get this great idea to start a new build. We have a house now and have room for a larger tank. I quickly sold my 80gal (http://reefcentral.com/forums/showthread.php?t=1832132). I put it up on local forum and it sold in 1 day! GRRRREAT!!! So I think to myself, lets do a deep 180. I look at some tanks and decide I want a 60"x30"x24". After several emails with one of my LFS, we set a price. I said I have cash! Price went even lower. GRRRREAT! I order the tank. A basic Visio with black silicone with center trapazoidal overflow drilled for the bean. Didn't opt for the fancy stuff because I think eventually this will be a FO tank. Money down on the counter. Receipt in hand. "Be hur next wednesday" -LFS. I go to pick up my new toy. I look at it and it seems a little longer in person than I thought it would. It's a smaller LFS and I figure the building is tight and maybe the tank looks longer because of some sort of optical illusion. The LFS dude tells me the tank is the biggest he's ever ordered and it's blocking almost his whole walk way to his register. Then it hits me... This tank is not 5' long! I'm a about 6'1". I lay down next to the tank and we're the same size. DAMN!!! I guess in all the hussle of quickly ordering the tank, so I could have in his next shipment, the LFS ordered a standard 180. The dude was complety embarresed. It was his mistake and he admitted it. He asked me to think about it and let him know what I wanted to do. I talked it over with my wife and my cousin (datsun owner in my sig) and they both liked the idea of a longer tank. The wall the tank is going on is about 15' long. They were thinking that at 30'' deep, the tank would stick out too far and look "weird". Well after thinking about for awhile, I soon felt the same way. But if had wanted to take up more wall space, I would have got a 240! I was still undecided and called the LFS to see what they would do to make it right. LFS says, " I can take the hit, it's my F-up." The dude was legit and crazy honest. Since he was so honest about the mess up, I felt really bad about making him take a loss on the tank. So I decided to keep it. LFS was only charging me a small mark up. And I mean SMALL! He beat another LFS price for me. So lets just say that when I shop there now, I never pay full price anymore. And that's how this journey of building the wrong tank begain.

Pics cooming soon...

Pics cooming soon...