naterealbig

Premium Member

A little background, skip if you like................

Ok, so I'm a poor college student, currently attending USF in hopes of one day earning my Mechanical Engineering degree. Before I moved to florida (was stationed in GA when I got out of the military, although FL has always been my home) I had a 110 that I sold off, and thought that my Solana would keep me happy. The reward I got from the small tank did not outweigh the time it took to maintain, and with going to school and working full time, decided it was best if I just didn't have a tank. I sold it off, along with a ton of other stuff, which some of you may remember.

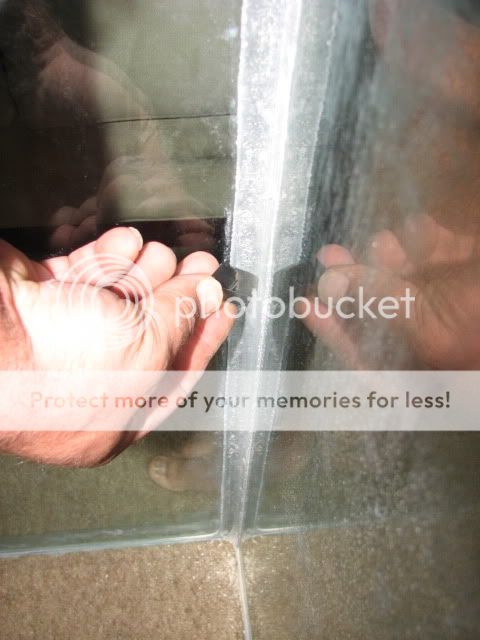

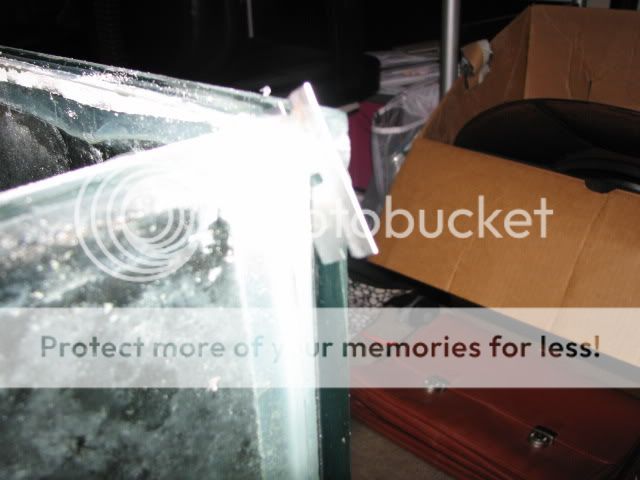

Well my brother works in a LFS in Pensacola, and moves tanks as part of his job. While relocating a 115 cube, one of the guys who was helping move the tank, dropped his end onto a tile floor, severely damaging the bottom of the tank. My brother called me for advice, and I told him that repairing the tank would be a lot more involved then he realized, and the store owner simply decided to replace the womans tank and get rid of the cube.

I'm not sure at what point I decided I would ask my brother if they still had the broken tank, but I did. I talked him into keeping the tank for me, and made plans to meet him in Tallahassee to pick up the aquarium and stand in exchange for $100. And that's the beginning. The tank has been sitting in my living room for a coupe of weeks now, and I have finally started working on and buying equipment for it.

I am starting this thread, not because I feel I'm doing something amazing, but rather because I would love feed back and comments on my methods and planning. 50 sets of eyes are better than one. I have chosen my equipment after lots of research, and I am trying to avoid product wars.

Please give me your input and ideas, as I would love help with the big project. Hopefully I will end up with something that is appealing to the eye.

Enjoy,

Nate

Ok, so I'm a poor college student, currently attending USF in hopes of one day earning my Mechanical Engineering degree. Before I moved to florida (was stationed in GA when I got out of the military, although FL has always been my home) I had a 110 that I sold off, and thought that my Solana would keep me happy. The reward I got from the small tank did not outweigh the time it took to maintain, and with going to school and working full time, decided it was best if I just didn't have a tank. I sold it off, along with a ton of other stuff, which some of you may remember.

Well my brother works in a LFS in Pensacola, and moves tanks as part of his job. While relocating a 115 cube, one of the guys who was helping move the tank, dropped his end onto a tile floor, severely damaging the bottom of the tank. My brother called me for advice, and I told him that repairing the tank would be a lot more involved then he realized, and the store owner simply decided to replace the womans tank and get rid of the cube.

I'm not sure at what point I decided I would ask my brother if they still had the broken tank, but I did. I talked him into keeping the tank for me, and made plans to meet him in Tallahassee to pick up the aquarium and stand in exchange for $100. And that's the beginning. The tank has been sitting in my living room for a coupe of weeks now, and I have finally started working on and buying equipment for it.

I am starting this thread, not because I feel I'm doing something amazing, but rather because I would love feed back and comments on my methods and planning. 50 sets of eyes are better than one. I have chosen my equipment after lots of research, and I am trying to avoid product wars.

Please give me your input and ideas, as I would love help with the big project. Hopefully I will end up with something that is appealing to the eye.

Enjoy,

Nate