zachtos

Active member

The tank partition/stand build progress

The family room/finished basement is the chosen room.

Introduction:

I'm an Electrical Engineer living in Milwaukee, Wisconsin, living out my dream job designing laser tag gear for a living! Basically get paid to go in every day and build cool stuff, show said stuff to my boss, watch him lose his mind, then figure out when we can find the time/funds to add it to the production line. We are designing the world's first high end outdoor laser tag gun aimed at the consumer market, it pairs with your smart phone to play high end games, similar to airsoft/paintball but better. I'm also married with a wife, 3 year old daughter and another kid on the way in January.

History:

Zachtos 240G reef - my old SPS reef that I ran 2007-2014 (google 'zachtos reef')

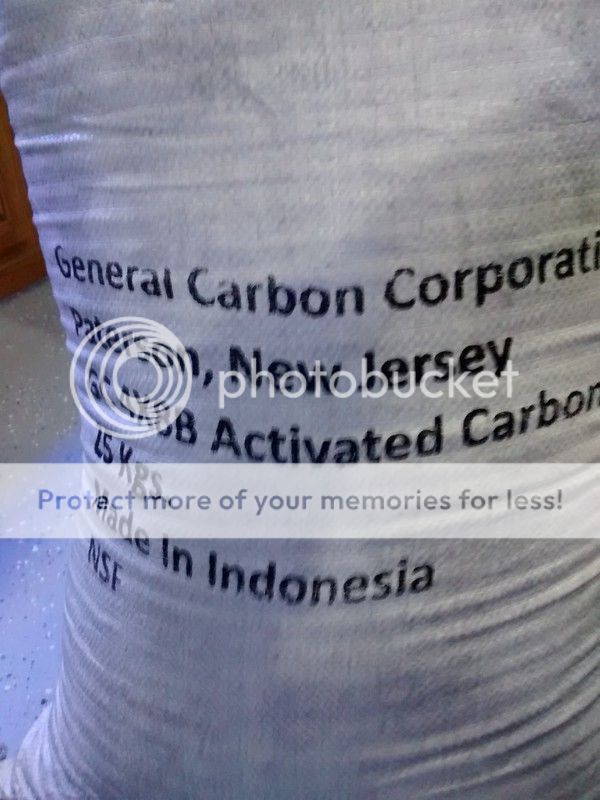

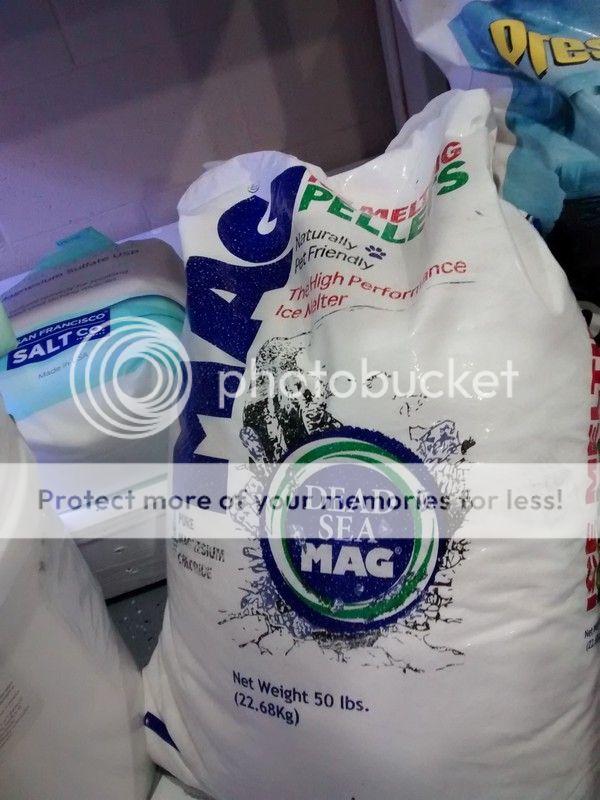

I've had a 240G reef before, so I'm a veteran (and the wife has already dealt with the addiction). I had to tear it down 2 years back to accept this job in another state, but I feel stable enough now to start again. In general, I like to DIY and experiment with many of the new trends in the hobby. I also work hard to keep costs down through energy consumption, full product life cycle analysis and bulk purchasing research. Such as buying carbon in 50 pound bags from a water purifcation plant, using driveway salts to supplement water chemistry, building my own LEDs to keep energy/heat/build costs low, heating with natural gas to keep energy costs low, insulating tanks to keep heat contained and fighting the ongoing battle with humidity control. I enjoy the system design phase more than the coral trimming phase. I am partial to SPS coral, tangs and some angel fish. I like running low nutrient for bright colors and planning for the future.

Plans:

This time I will improve the design to be more energy efficient, quieter and easier for maintenance. I will try my best to quarantine and have a proper frag system. I am spending money on certain items when I need high quality engineering, and am willing to DIY in other areas where I see room for improvement based on market products. I am still buying some items used to meet the budget of $12,500 (which is already kreeping to $14,000 to date, working to reduce)

Tank

Filtration

Flow

Lighting

Controllers

Heating/Cooling

Plumbing

Quarantine

Tank Room

Livestock plans:

Summary

The theme of the build is to minimize the tank room this time. Less open bodies of water so I won't have humidity issues. Powerful skimmer this time, instead of a DIY one that I always wondered about. Algae turf scrubber to pickup remaining nitrate/phosphate with natrual nutrient export technique. No expensive chemical filtration like GFO, just carbon in bulk for cheap water clarity. Energy efficiency with LED and gas water heating. I really wanted to try a bean/herbie silent overflow this time, but It's not compatible with drain feeding a turf scrubber because of level inconsistency. I have a feeling the skimmer will be fairly loud anyway, so why bother? The return pumps and flow pumps are all quiet, so should only hear the trickle from the durso and skimmer suck/hissing. I am hoping gravity can do my water changes via ball valve in bottom of sump and then refill via valve from an elevated 55G barrel full of SW, just run out a 25' pool hose as needed. I want to avoid a calcium reactor this time, and try for pure 3 part dosing. I got tired of changing CaReactor media, O-rings, pumps, PH probes/controllers, solenoids, CO2 refills... I think the overall cost for 3 part will be cheaper, and more reliable, but I will find out, and I arleady got 50 lbs of MagFlake - deadsea, Epsom Salt, SodaAsh/pool, CaCl prestone driveway heat.

The family room/finished basement is the chosen room.

Introduction:

I'm an Electrical Engineer living in Milwaukee, Wisconsin, living out my dream job designing laser tag gear for a living! Basically get paid to go in every day and build cool stuff, show said stuff to my boss, watch him lose his mind, then figure out when we can find the time/funds to add it to the production line. We are designing the world's first high end outdoor laser tag gun aimed at the consumer market, it pairs with your smart phone to play high end games, similar to airsoft/paintball but better. I'm also married with a wife, 3 year old daughter and another kid on the way in January.

History:

Zachtos 240G reef - my old SPS reef that I ran 2007-2014 (google 'zachtos reef')

I've had a 240G reef before, so I'm a veteran (and the wife has already dealt with the addiction). I had to tear it down 2 years back to accept this job in another state, but I feel stable enough now to start again. In general, I like to DIY and experiment with many of the new trends in the hobby. I also work hard to keep costs down through energy consumption, full product life cycle analysis and bulk purchasing research. Such as buying carbon in 50 pound bags from a water purifcation plant, using driveway salts to supplement water chemistry, building my own LEDs to keep energy/heat/build costs low, heating with natural gas to keep energy costs low, insulating tanks to keep heat contained and fighting the ongoing battle with humidity control. I enjoy the system design phase more than the coral trimming phase. I am partial to SPS coral, tangs and some angel fish. I like running low nutrient for bright colors and planning for the future.

Plans:

This time I will improve the design to be more energy efficient, quieter and easier for maintenance. I will try my best to quarantine and have a proper frag system. I am spending money on certain items when I need high quality engineering, and am willing to DIY in other areas where I see room for improvement based on market products. I am still buying some items used to meet the budget of $12,500 (which is already kreeping to $14,000 to date, working to reduce)

Tank

- 300G deep dimension marineland glass tank (used - starphire sides $1000)

- DIY tank stand (2x8 top, and 2x4 for remainder, based on DIY stand thread on RC)

- Barebottom HDPE sheets (no sand/nutrients)

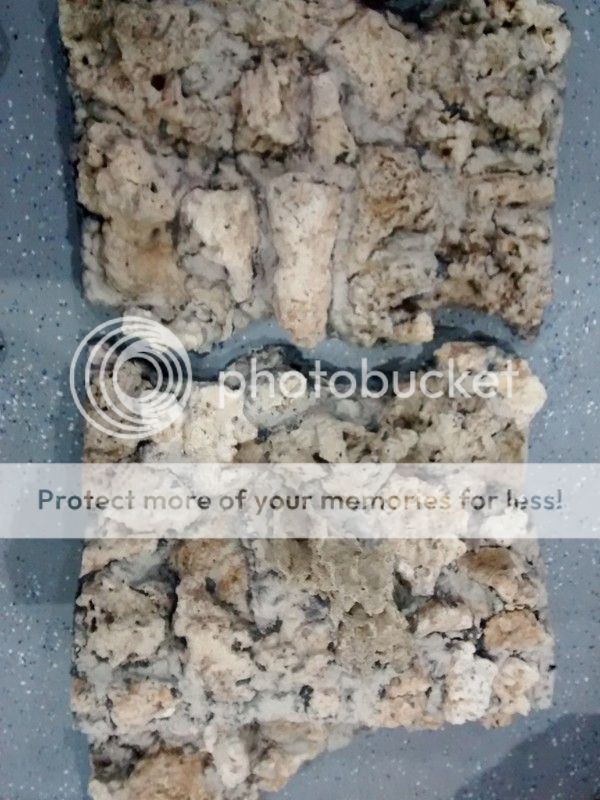

- DIY foam background (great stuff pond foam, egg crate and pieces of rock)

- Mesh or glass covers undecided (light loss vs humidity control still a debate)

Filtration

- 400-500lbs of live rock in display

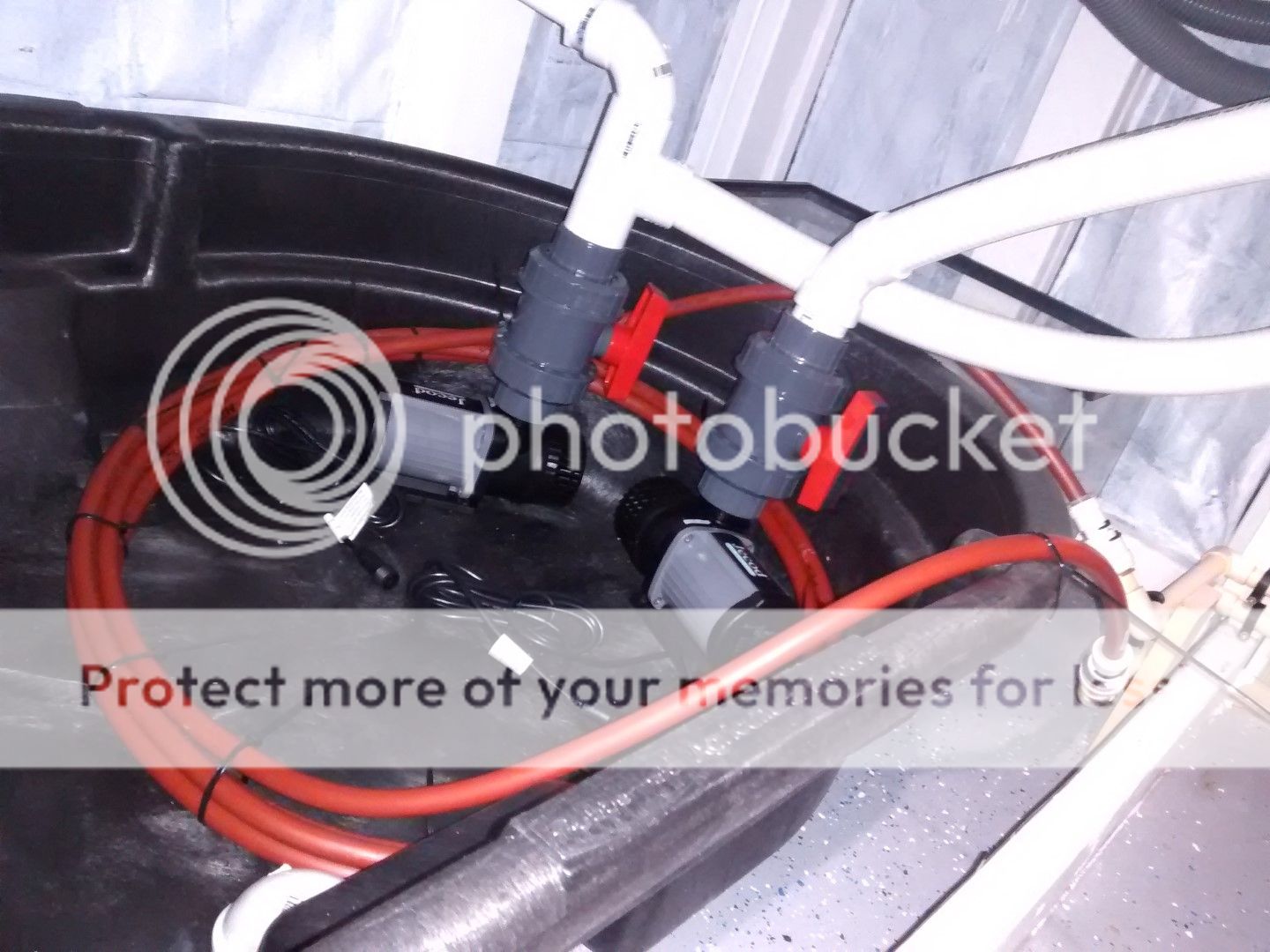

- 50G rubbermaid sump

- Super Reef Octopus SRO-5000INT 10" In Sump Protein Skimmer (bought for $500 with auto neck cleaner, and use with my old 5000 Bubble Blaster pump)

- Algae Turf Scrubber DIY (24"x18"), rated for about 35 cubes of frozen food per day

- Carbon in a 2 little fishes reactor (2-4 cups/month, I buy 50 lbs per year for $140)

- 10-15% bi-weekly water changes

Flow

- Two(2) Vortech MP-60 (used - upgrading to quiet drives)

- One(1) or Two(2) Tunze wave box - new (will decide if need second unit later)

Lighting

- LED DIY fixture for display tank (royal blue, blue, cool white, violet, deep red - still planning density and ratios)

- LED DIY fixture for both sides of turf scrubber (660nm x 24 per side, 420nm x6 per side)

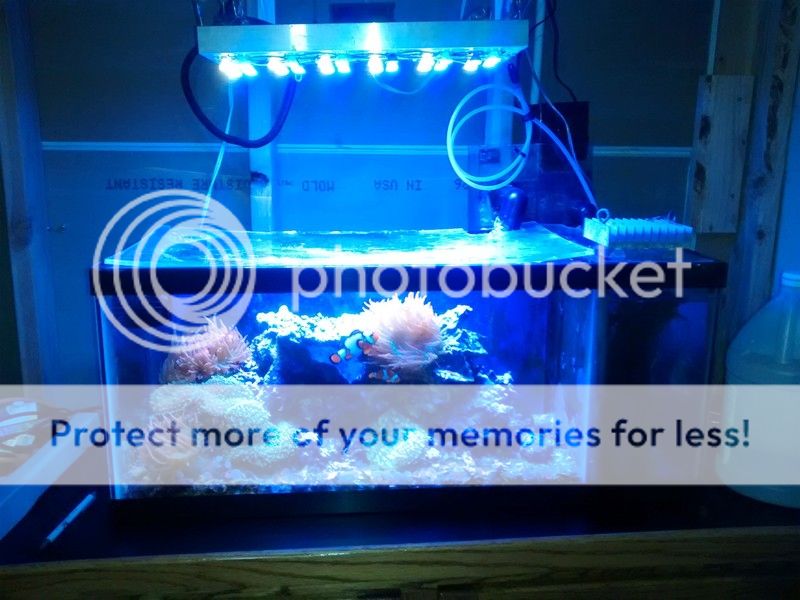

- Existing DIY LED fixture for frag tank (36LED of 2:1 royal blue to neutral white)

- moonlight (royal blue LED for Display x 6-12)

- Sliding light rail for LED fixture?

Controllers

- 3 part solution doser (Jebao v2) - will dose according to Randy's old recipe - No Ca Reactor this time

- DIY microcontroller - undecided what I want desgin yet (lights, feed timer, auto feeder, PH, water sensor, bluetooth/WIFI, etc)

- ATO float switches and relays connected to dual aqualufters fed from 55G barrel of water

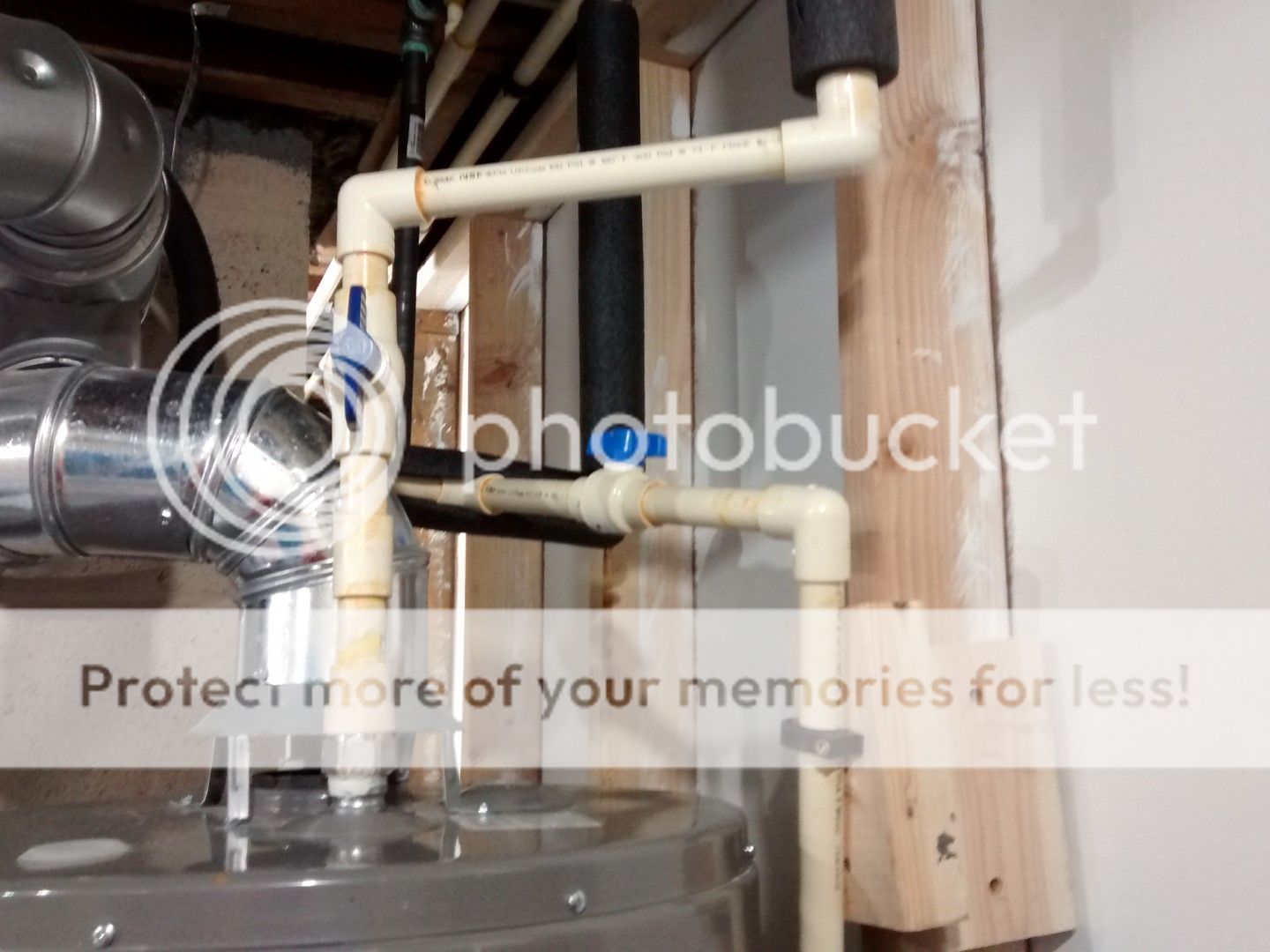

- Ranco temperature controller for gas water heater closed PEX loop

- battery backup for return pump x 1

Heating/Cooling

- -PEX coil connected to water heater with TACO hotwater recirculation pump and Ranco temperature controller (NO RESISTIVE HEATERS)

- -Cooling not usually needed in basement setup w/ LED in northern USA, but we shall see.

Plumbing

- Two(2) - DCS-9000 Jebao v3 return pumps - cheap, energy efficient, unreliable though, so am wiring in parallel with 1 unit on battery backup

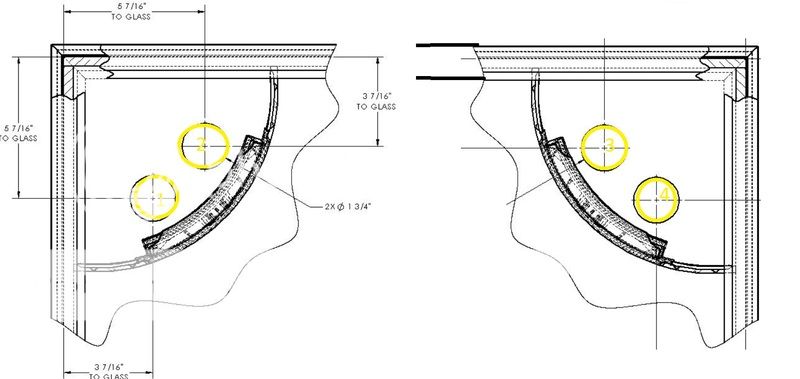

- Four(4) - 1" durso standpipes to sump which will all drain feed the algae turf scrubber waterfall (bean/herbie are not easy to use for a drain fed device)

- One(1) - 1" durso standpipe from frag tank to sump

- Water change station = Two(2) 55 gallon barrels, 1 for ATO, 1 for SE

- returns = flexible and rigid PVC,

- drains = flexible pool hose

Quarantine

- 40G breeder glass tank

- CPR bakpack skimmer and mag3 pump

- automatic feeder

- PVC pipe hiding places

- Dim LED light if any?

- small resistive heater if needed (not sure I need though?)

- *unknown what chemicals I need yet

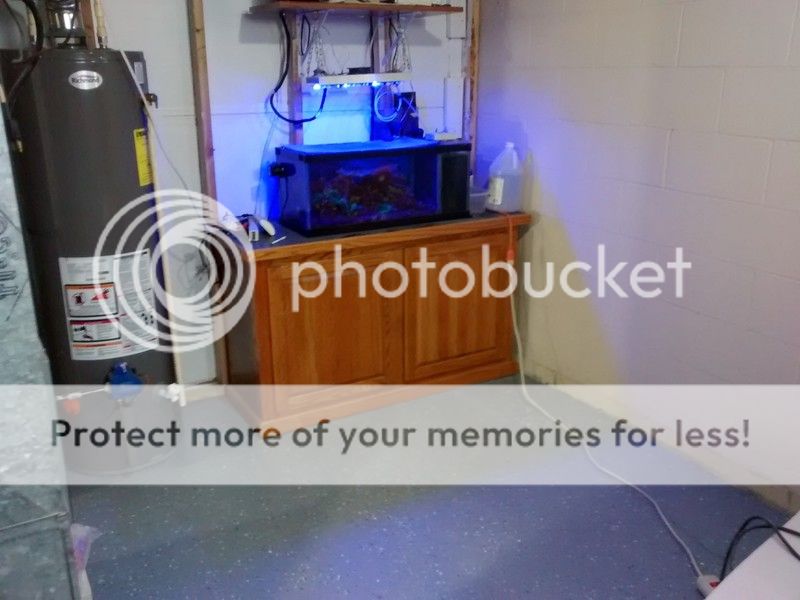

Tank Room

- -300G sealed in wall

- -skimmer/ATS/returns/carbon in sump under main tank

- -Frag tank plumbed to DT sump

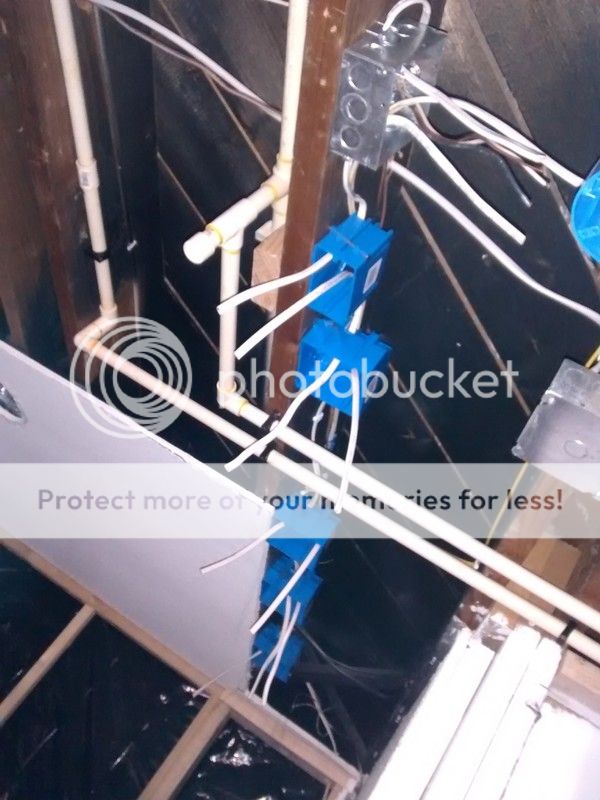

- -two circuits (20A with GFI outlets for DT lights, nonGFI for pumps) and other 15A circuit for frag/QT/dehumidifier

- -QT tank is independent system

- -WC station using two 55G barrels and valves, mag9 for mix pump

- -Water changes with a dip/depth gauge and pool hose to drain/refill via gravity

- -storage of salts/carbon underneath WC station

- -dehumidifer under frag tank stand

- -extra stand by wash basin for extra QT tank if need

- -stands coated with epoxy resin

- -floor coated with new epoxy paint

- -seams filled with silicone and/or rubber trim

- -new 5.0cf deep freezer for fish food (and eventually an automated feeder system to DT)

Livestock plans:

- Tangs, Angels, SPS (monti and millipora) , nothing solid yet.

Summary

The theme of the build is to minimize the tank room this time. Less open bodies of water so I won't have humidity issues. Powerful skimmer this time, instead of a DIY one that I always wondered about. Algae turf scrubber to pickup remaining nitrate/phosphate with natrual nutrient export technique. No expensive chemical filtration like GFO, just carbon in bulk for cheap water clarity. Energy efficiency with LED and gas water heating. I really wanted to try a bean/herbie silent overflow this time, but It's not compatible with drain feeding a turf scrubber because of level inconsistency. I have a feeling the skimmer will be fairly loud anyway, so why bother? The return pumps and flow pumps are all quiet, so should only hear the trickle from the durso and skimmer suck/hissing. I am hoping gravity can do my water changes via ball valve in bottom of sump and then refill via valve from an elevated 55G barrel full of SW, just run out a 25' pool hose as needed. I want to avoid a calcium reactor this time, and try for pure 3 part dosing. I got tired of changing CaReactor media, O-rings, pumps, PH probes/controllers, solenoids, CO2 refills... I think the overall cost for 3 part will be cheaper, and more reliable, but I will find out, and I arleady got 50 lbs of MagFlake - deadsea, Epsom Salt, SodaAsh/pool, CaCl prestone driveway heat.