ReefingHavoc

Member

I've been planning this build for nearly a year and finally have house updates out of the way to start. Here's the plan:

120 gallon glass rimless (48x24x24) display

75 gallon(ish) acrylic basement sump -- to be built

Lighting:

48" Aquatic Life T5HO Hybrid

Ecotech Radion xr15

Skimmer:

Vertex Omega 180i

Return Pump:

Reeflo Swordtail 1750

Powerheads:

Dual Maxpect Gyre XF230

Overflow:

Synergy Reef Systems 16" Shadow

Controller:

Reef Angel Star

A couple of thoughts on my approach:

Hoping to share with others my progress and elicit ideas from the community.

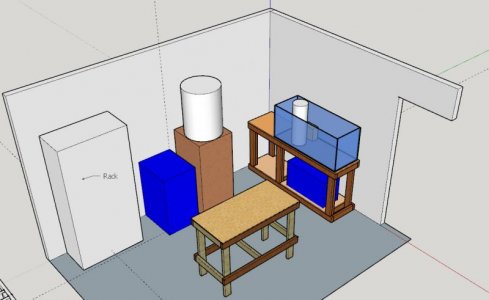

SketchUp file of fish room attached

For now, I've started on the sump stand. Pretty standard design to hold a 48x18x20 acrylic tank that i'm building. I'll be picking up the cut sheets later this week. Debated on paint or sealer for the top of the stand but decided on using some leftover Waterlox, which should protect things nicely.

I'll continue to post as things progress

120 gallon glass rimless (48x24x24) display

75 gallon(ish) acrylic basement sump -- to be built

Lighting:

48" Aquatic Life T5HO Hybrid

Ecotech Radion xr15

Skimmer:

Vertex Omega 180i

Return Pump:

Reeflo Swordtail 1750

Powerheads:

Dual Maxpect Gyre XF230

Overflow:

Synergy Reef Systems 16" Shadow

Controller:

Reef Angel Star

A couple of thoughts on my approach:

- Looking to run Triton to ease the number of water changes

- Will have 29 gallon quarantine

- Looking to build in redundancy to the system

Hoping to share with others my progress and elicit ideas from the community.

SketchUp file of fish room attached

- The blue block is my sink

- I'll have a 55 gallon drum for keeping salt water ready

- Still figuring out a top off container

- Stand will house quarantine below

For now, I've started on the sump stand. Pretty standard design to hold a 48x18x20 acrylic tank that i'm building. I'll be picking up the cut sheets later this week. Debated on paint or sealer for the top of the stand but decided on using some leftover Waterlox, which should protect things nicely.

I'll continue to post as things progress