Hi Guys,

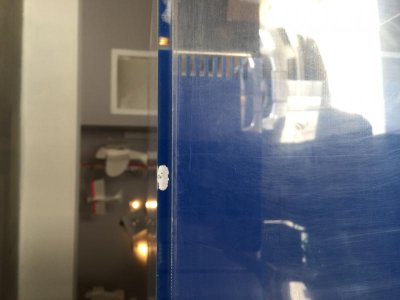

I picked up a lot of gear from a guy getting out of the hobby and I have an issue with 1 seam on the tank. The value of the deal wasn't in the 150 gallon tank, but I really would like to use it. It's 72 x 20 x 24. The idea was to restore the tank back to new condition and do FOWLR tank with it. I saw it setup full and there are no leaks. The first picture shows it full of water and you can clearly see the bad spots. The defects started from the outside of the seam and I guess are moving inwards. The tank looks like its going to polish up real nice, but I had a glass tank with a bad seam once and it wasn't a lot of fun. Safe to say I am worried a bit this time around. I show a picture with the adhesive I bought but after reading a bit I'm not sure if I'm going after this correctly. I thought with the needle applicator with the weldon 4, I could get some in there and put a small piece of wood on the spot and throw a clamp on it front to back and that would be that. I am now thinking that it won't work and I may have to run an acrylic 1/2" square rod down both front seams and just deal with the looks. Not really sure at this point. Please let me know what you think. All opinions are welcomed! The pictures are showing the bad seam which is the front left side. They are in order showing the top first and moving to the bottom of the seam. Thanks.

I picked up a lot of gear from a guy getting out of the hobby and I have an issue with 1 seam on the tank. The value of the deal wasn't in the 150 gallon tank, but I really would like to use it. It's 72 x 20 x 24. The idea was to restore the tank back to new condition and do FOWLR tank with it. I saw it setup full and there are no leaks. The first picture shows it full of water and you can clearly see the bad spots. The defects started from the outside of the seam and I guess are moving inwards. The tank looks like its going to polish up real nice, but I had a glass tank with a bad seam once and it wasn't a lot of fun. Safe to say I am worried a bit this time around. I show a picture with the adhesive I bought but after reading a bit I'm not sure if I'm going after this correctly. I thought with the needle applicator with the weldon 4, I could get some in there and put a small piece of wood on the spot and throw a clamp on it front to back and that would be that. I am now thinking that it won't work and I may have to run an acrylic 1/2" square rod down both front seams and just deal with the looks. Not really sure at this point. Please let me know what you think. All opinions are welcomed! The pictures are showing the bad seam which is the front left side. They are in order showing the top first and moving to the bottom of the seam. Thanks.