jml1149

New member

I've been using the COR-20 for a couple of weeks now, and I have some general impressions to share. Any questions, please feel free and I'll do my best to answer.

I'm replacing a Sicce 5.0, which is now my backup pump.

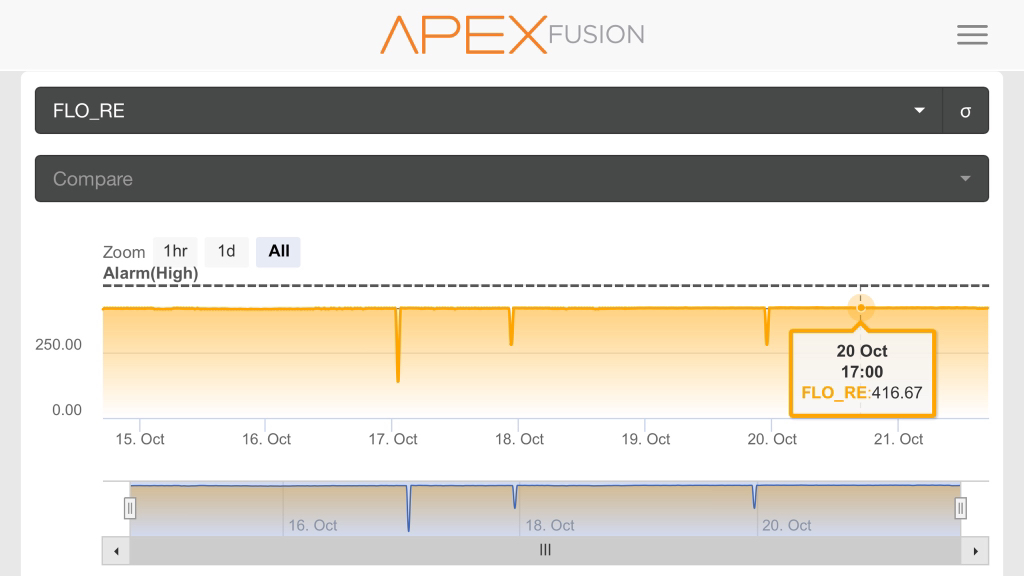

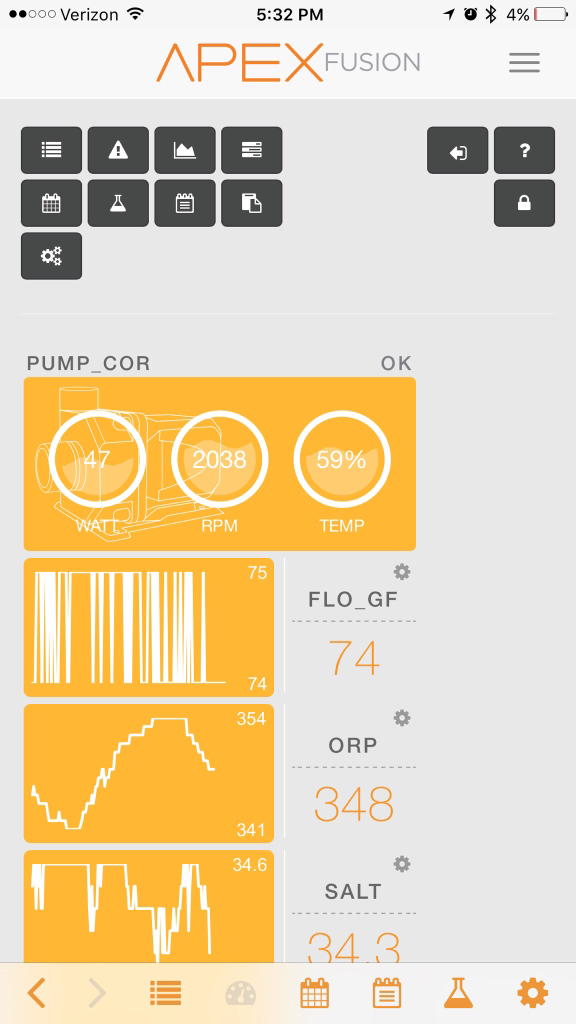

There are two key features to the COR that I really enjoy. The first is the integration into the Apex universe. At this point, I can't imagine ever owning a critical piece of reef gear that was not Apex compatible. I travel a bunch for work, and even during this Beta test I spent a week out of state. The ability to just dial into my Apex head unit and get detailed status of everything, I really do find it to be reassuring. The Apex Fusion tile provides WATTS, RPM, and TEMP, which is great But, the COR also provides diagnostic functions via Fusion, including Run Dry, Over Voltage, Under Voltage, Overcurrent, and Temp. This way, if I have an issue, I at least have an idea of what's going on. I've tested the Run Dry accidentally (oops) and it worked no problem.

A couple of my local friends are Apex users, but find the programming challenging. I do a lot of Apex coding for other people's tanks. Here, it's not unique to the COR, but the Fusion Tasks are excellent ways to follow a couple command prompts and the system does the programming for you. It could not be easier to set this up in the Apex environment. There's literally no coding required.

The other thing I'm thrilled about with this pump is called IQ-Level adjustment. We set MAX and MIN levels for the COR using either the buttons on the COR control module or via an Apex Fusion interface. The MAX is used as the normal operating speed of the pump, and the MIN is used for FEED modes.

This might not sound super exciting, and when I first heard about it I literally said "meh", and I didn't think I would use it. But I gave it a go and this is great. I currently have my COR MIN speed set to 5%. This is juuuust enough flow to trickle water up through the return, which in turn keeps the tank level at the same height and the returns full of water. I have my MAX speed set to 58%, which matches the flow I was getting out of the Sicce 5.0. I measure this via 1" FMM sensor.

So now, when I hit the FEEDA mode, instead of going OFF, it goes to 5%. What I really like about this though, is after the FEED mode is over, and when the pump kicks back on, I don't get that air-water slurry that always came rocketing out of the return with the Sicce. It's like a motorized check valve, but without the poor reliability. There's also a soft start feature built in, so the speed doesn't just jump from 5% to 58%.

Currently, I'm testing the COR in standalone mode, so no Apex connected. Sort of kills the first "feature", , but does not interrupt the second. The IQ-Level can be set via the buttons on the COR control module, no Apex required. There are two buttons, left and right. Left slows the pump, right speeds it up. Dial in the speed you want, hold the two buttons in for three seconds, and boom, the max level is set.

, but does not interrupt the second. The IQ-Level can be set via the buttons on the COR control module, no Apex required. There are two buttons, left and right. Left slows the pump, right speeds it up. Dial in the speed you want, hold the two buttons in for three seconds, and boom, the max level is set.

For the min, activate the FEEDA mode by holding the right button in for 3 seconds, the COR will go into slow speed. Dial in the desired MIN speed, hold the two buttons in for three seconds, and boom, the min level is set.

Now, when you activate the FEEDA mode via COR module, the same levels will be held. Neptune also stores these values onboard the COR control module, so if power is lost or cycled, the IQ levels do not change.

One thing that does irk me a touch about the COR in standalone mode is is the number of button pushes required to get from 0% to 100%. You can get pretty high resolution on the speeds here. However, I can't think of a better way to do this. You need to be able to dial in flow, and literally the only way in a non-Apex connected state to do this is going to be by pushing manual buttons until you get where you want.

That being said, the old way with my Sicce 5.0 to control speed was to get under the tank and adjust a 1" ball valve. I would MUCH rather push the buttons than do that again. What a poor design that was on my part. And how often do I really adjust return pump flow once it's dialed in? Pretty much never.

I'll keep updating this thread for the next couple of weeks. I'm trying to be as unbiased as possible, but there's a certain level of "awesomeness" about upgrading from a fixed speed AC pump to a controllable DC pump that I would be digging for probably any of the DC pumps out there. Cool new stuff to mess with I didn't have previously. But, I am a hardcore Apex user, and the seamless integration into Fusion puts this way over the top for me. It really is exceptional stuff.

Also, I can try to get some pictures and screenshots up when I figure out the easiest way. May be via Tapatalk.

I'm replacing a Sicce 5.0, which is now my backup pump.

There are two key features to the COR that I really enjoy. The first is the integration into the Apex universe. At this point, I can't imagine ever owning a critical piece of reef gear that was not Apex compatible. I travel a bunch for work, and even during this Beta test I spent a week out of state. The ability to just dial into my Apex head unit and get detailed status of everything, I really do find it to be reassuring. The Apex Fusion tile provides WATTS, RPM, and TEMP, which is great But, the COR also provides diagnostic functions via Fusion, including Run Dry, Over Voltage, Under Voltage, Overcurrent, and Temp. This way, if I have an issue, I at least have an idea of what's going on. I've tested the Run Dry accidentally (oops) and it worked no problem.

A couple of my local friends are Apex users, but find the programming challenging. I do a lot of Apex coding for other people's tanks. Here, it's not unique to the COR, but the Fusion Tasks are excellent ways to follow a couple command prompts and the system does the programming for you. It could not be easier to set this up in the Apex environment. There's literally no coding required.

The other thing I'm thrilled about with this pump is called IQ-Level adjustment. We set MAX and MIN levels for the COR using either the buttons on the COR control module or via an Apex Fusion interface. The MAX is used as the normal operating speed of the pump, and the MIN is used for FEED modes.

This might not sound super exciting, and when I first heard about it I literally said "meh", and I didn't think I would use it. But I gave it a go and this is great. I currently have my COR MIN speed set to 5%. This is juuuust enough flow to trickle water up through the return, which in turn keeps the tank level at the same height and the returns full of water. I have my MAX speed set to 58%, which matches the flow I was getting out of the Sicce 5.0. I measure this via 1" FMM sensor.

So now, when I hit the FEEDA mode, instead of going OFF, it goes to 5%. What I really like about this though, is after the FEED mode is over, and when the pump kicks back on, I don't get that air-water slurry that always came rocketing out of the return with the Sicce. It's like a motorized check valve, but without the poor reliability. There's also a soft start feature built in, so the speed doesn't just jump from 5% to 58%.

Currently, I'm testing the COR in standalone mode, so no Apex connected. Sort of kills the first "feature",

For the min, activate the FEEDA mode by holding the right button in for 3 seconds, the COR will go into slow speed. Dial in the desired MIN speed, hold the two buttons in for three seconds, and boom, the min level is set.

Now, when you activate the FEEDA mode via COR module, the same levels will be held. Neptune also stores these values onboard the COR control module, so if power is lost or cycled, the IQ levels do not change.

One thing that does irk me a touch about the COR in standalone mode is is the number of button pushes required to get from 0% to 100%. You can get pretty high resolution on the speeds here. However, I can't think of a better way to do this. You need to be able to dial in flow, and literally the only way in a non-Apex connected state to do this is going to be by pushing manual buttons until you get where you want.

That being said, the old way with my Sicce 5.0 to control speed was to get under the tank and adjust a 1" ball valve. I would MUCH rather push the buttons than do that again. What a poor design that was on my part. And how often do I really adjust return pump flow once it's dialed in? Pretty much never.

I'll keep updating this thread for the next couple of weeks. I'm trying to be as unbiased as possible, but there's a certain level of "awesomeness" about upgrading from a fixed speed AC pump to a controllable DC pump that I would be digging for probably any of the DC pumps out there. Cool new stuff to mess with I didn't have previously. But, I am a hardcore Apex user, and the seamless integration into Fusion puts this way over the top for me. It really is exceptional stuff.

Also, I can try to get some pictures and screenshots up when I figure out the easiest way. May be via Tapatalk.