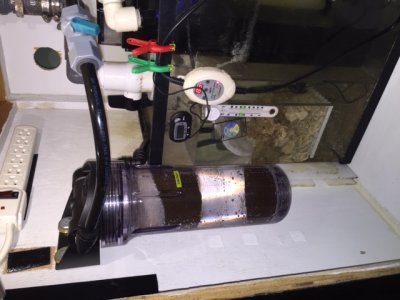

I just finished installing a BRS GFO Reactor. Went fairly smooth overall. I only put one cup of the GFO mix in there and let it run into a bucket until the water came out clear. I adjusted it as the instructions said so that only the top of the stuff is moving around. For some reason as you can see in the photo about half of the GFO is at the top with the foam disc, and the other half is at the bottom with the top part moving around. I don't think this is how its supposed to be but have no idea how to fix it. There is an air release which I played around with but it doesn't seem to do much.

Does anyone know what could be the problem?

Thanks

Does anyone know what could be the problem?

Thanks