Hi all not sure how much info is out there but i need some help on glass thickens for a drop off tank !!

i've built a few tanks in my time the biggest been 2.5 x 1 x 1m in 15mm

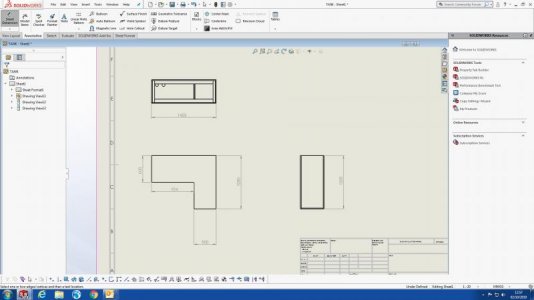

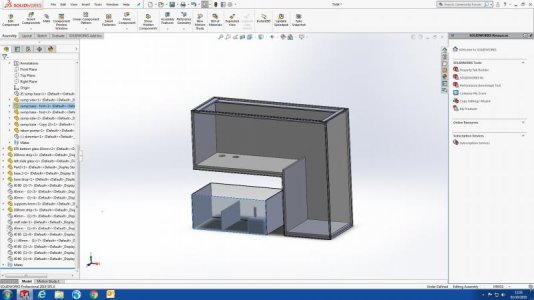

the L shape drop off is a new challenge tho mainly been the front and back panel

im told the tightest corner they can achieve is a rad of 8mm so that the front and back panne sit out side of the base glass not like conventional tanks

i've done the front and back in 19mm but im unsure if the sides need to be the same etc ?

i've built a few tanks in my time the biggest been 2.5 x 1 x 1m in 15mm

the L shape drop off is a new challenge tho mainly been the front and back panel

im told the tightest corner they can achieve is a rad of 8mm so that the front and back panne sit out side of the base glass not like conventional tanks

i've done the front and back in 19mm but im unsure if the sides need to be the same etc ?