BlueWorldJeff

Member

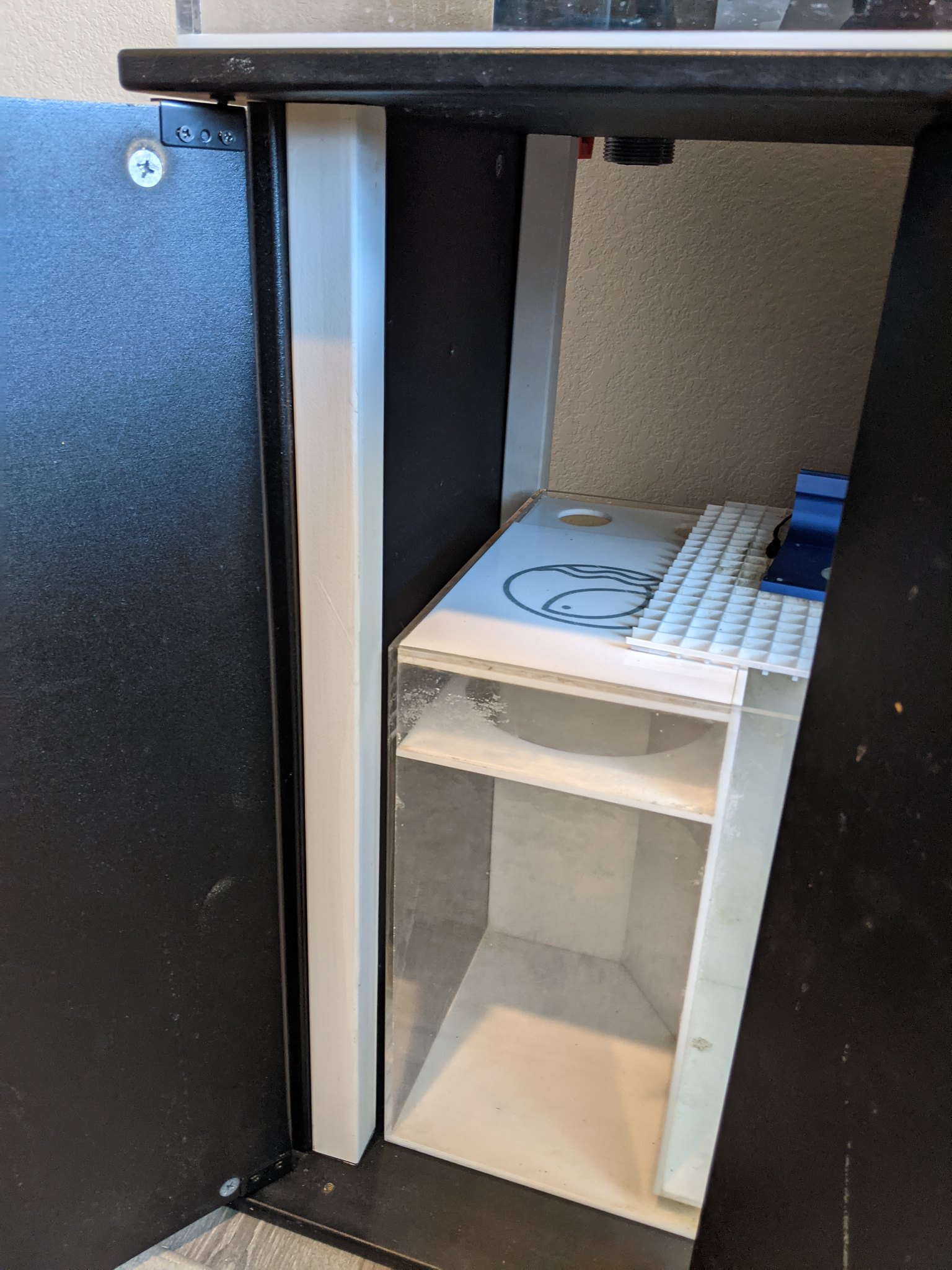

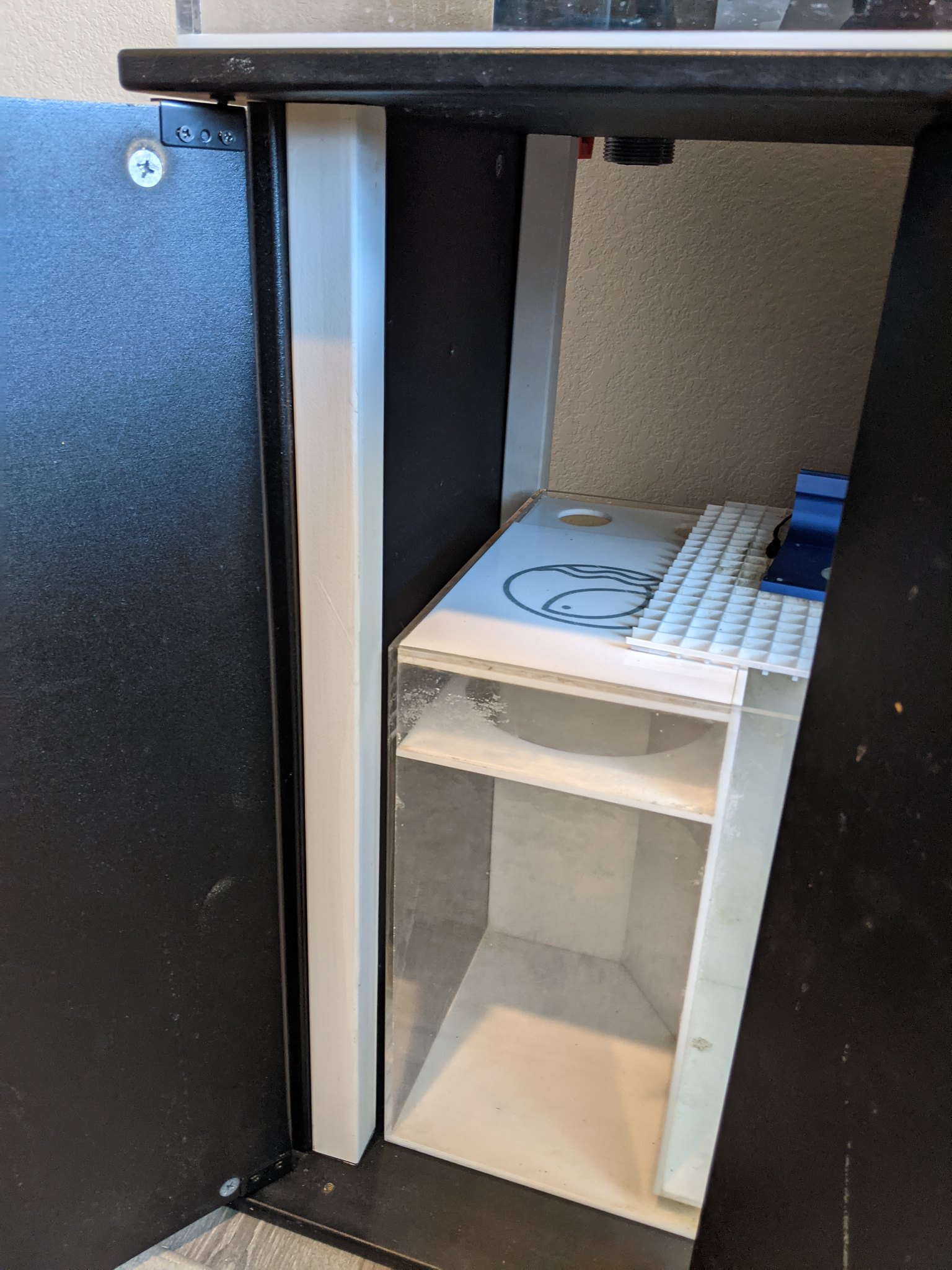

I'm looking to get my 36" W x 17"D x 12" H acrylic tank back up and running. I sold my old sump, so I bought a eshopps sump that fits in the stand I have.

The stand is a Petco special I believe, put together with cam locks. The door on the front is very small, not allowing much room to access all the chambers of the sump.

My idea was to use the two front panels that are on either side of the door as extra doors. I just removed the cam locks and put hinges on them. Now the whole front opens and I can access everything.

The problem is that without the front supports, the whole stand is super flimsy. It has a ton of horizontal flex. I added 2"x2" supports to all four corners, for extra support of the tank as well as to limit flex. They are tied to the top and bottom of the stand with screws and one screw in the side support.

I feel with a full tank of water on the stand, I need more bracing for the stand. There is one vertical support in the back, but I dont think its enough. Should I run a horizontal brace across the middle of the back of the tank to limit flexing?

The stand is a Petco special I believe, put together with cam locks. The door on the front is very small, not allowing much room to access all the chambers of the sump.

My idea was to use the two front panels that are on either side of the door as extra doors. I just removed the cam locks and put hinges on them. Now the whole front opens and I can access everything.

The problem is that without the front supports, the whole stand is super flimsy. It has a ton of horizontal flex. I added 2"x2" supports to all four corners, for extra support of the tank as well as to limit flex. They are tied to the top and bottom of the stand with screws and one screw in the side support.

I feel with a full tank of water on the stand, I need more bracing for the stand. There is one vertical support in the back, but I dont think its enough. Should I run a horizontal brace across the middle of the back of the tank to limit flexing?