7thdarkangel

New member

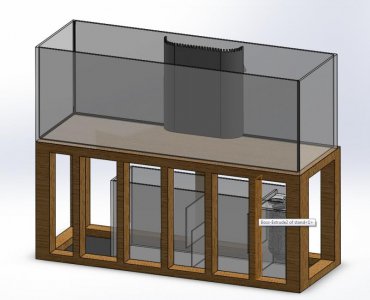

I have recently acquired a 180 gallon tank to replace my 4yr old 125 that was built into a wall. attached are the pictures of the 125. when I build the 125 in the wall I thought I did everything I wanted. (we all know 6 month down the road your cussing your self out) but I have no font access to the tank. now that I have a good opportunity to do a little reconstruction on the wall I would like to add this font access. the only problem is I cant come up with an appealing way of doing so.

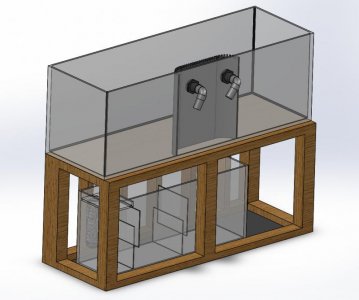

As for the tank, picture will come later. it is plan Jane none drilled. I will be building a center overflow with 2 1.5 bulk heads with over the top return(personal preference).

Also this may be a slower build. work has been picking up and less time is available for fun stuff.

As for the tank, picture will come later. it is plan Jane none drilled. I will be building a center overflow with 2 1.5 bulk heads with over the top return(personal preference).

Also this may be a slower build. work has been picking up and less time is available for fun stuff.