MarsRover

New member

Hey everyone,

I have decided to start planning by big build. I figure i am about a year off from actually having this tank but since it's going to be a major project i need to start planning.

A little about me, I recently purchased a house, i am located in the San Gabriel Foothills, about 25 minutes outside of LA. I'm an engineer working for NASA. I did reefing and worked at an exotic fish and reptile shop all throughout high school. Then in college i stopped reefing and now that i have been settled in LA for 2.5 years with a steady job, it's time to get serious.

I presently have a ~50gal oceanic tank with MH & T5's. It has been going really well but space has always been an issue. I want to go to my forever tank. I'm anticipating having the new tank in question for at least 10 years.

The location i want to build it is in a wall between my living room, family room, and dining room. The idea is to have at least two sides visible. This is 100% a load bearing wall. I have not yet taken the walls off yet to see what madness lies beneath. Additionally, the floor is crappy hardwood floors ontop of a concrete slab, so at least i have that going for me. Downside is the concrete is likely not flat underneath (ugh... don't ask...) so that will need to be in the game plan as well.

As i said, BIG project.

So on to the fun stuff!

LOCATION: The wall presently behind my fish tank is the wall in question.

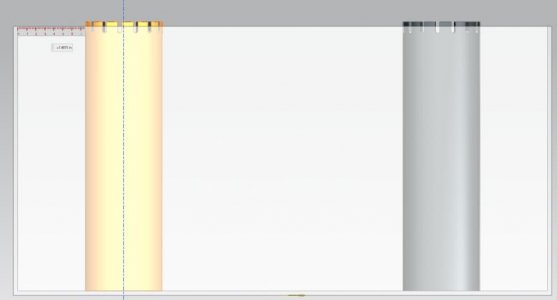

Going to have to put some sort of architectural column on one or both ends of the fishtank unfortunately....

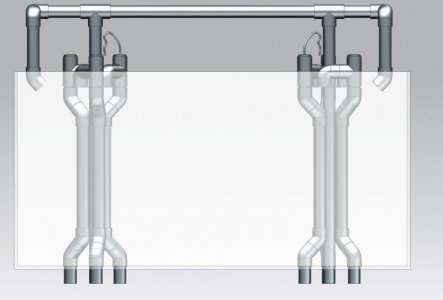

I'd have a cabinet for storage and sump under the tank (basically on the ground) and openable louver style doors on either side at the top that allows tank access and storage of lighting.

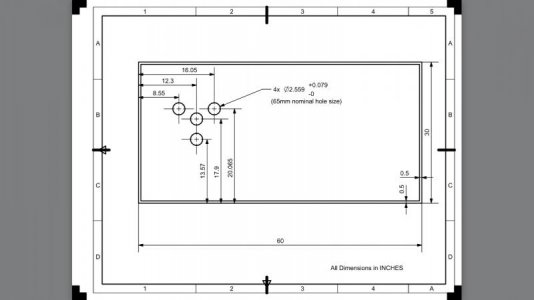

Ideal Display tank dimensions so far that i've measured are as follows: 60"x24"x36" (the 36 inches may be negotiable... depends on what is under the wall and how much access i'll be able to allow myself)

By my calculations, 60"x24"x46" ≈ 1872.84 lbs ≈ 224.42 gallons of H2O

Soon i will get some CAD models together to start virtually building.

Anyone know where i can find a tank of roughly these dimensions for a good price? Acrylic or Glass? If Glass what kind?

Thanks folks! Really looking forward to this adventure

I have decided to start planning by big build. I figure i am about a year off from actually having this tank but since it's going to be a major project i need to start planning.

A little about me, I recently purchased a house, i am located in the San Gabriel Foothills, about 25 minutes outside of LA. I'm an engineer working for NASA. I did reefing and worked at an exotic fish and reptile shop all throughout high school. Then in college i stopped reefing and now that i have been settled in LA for 2.5 years with a steady job, it's time to get serious.

I presently have a ~50gal oceanic tank with MH & T5's. It has been going really well but space has always been an issue. I want to go to my forever tank. I'm anticipating having the new tank in question for at least 10 years.

The location i want to build it is in a wall between my living room, family room, and dining room. The idea is to have at least two sides visible. This is 100% a load bearing wall. I have not yet taken the walls off yet to see what madness lies beneath. Additionally, the floor is crappy hardwood floors ontop of a concrete slab, so at least i have that going for me. Downside is the concrete is likely not flat underneath (ugh... don't ask...) so that will need to be in the game plan as well.

As i said, BIG project.

So on to the fun stuff!

LOCATION: The wall presently behind my fish tank is the wall in question.

Going to have to put some sort of architectural column on one or both ends of the fishtank unfortunately....

I'd have a cabinet for storage and sump under the tank (basically on the ground) and openable louver style doors on either side at the top that allows tank access and storage of lighting.

Ideal Display tank dimensions so far that i've measured are as follows: 60"x24"x36" (the 36 inches may be negotiable... depends on what is under the wall and how much access i'll be able to allow myself)

By my calculations, 60"x24"x46" ≈ 1872.84 lbs ≈ 224.42 gallons of H2O

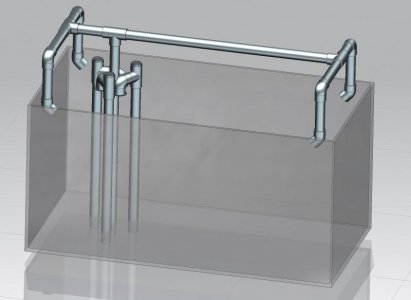

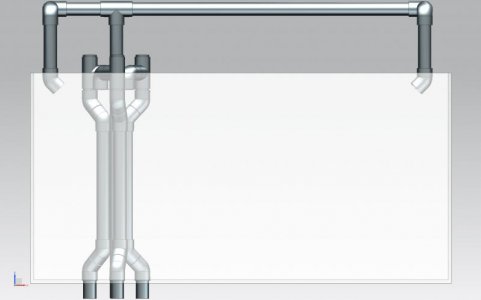

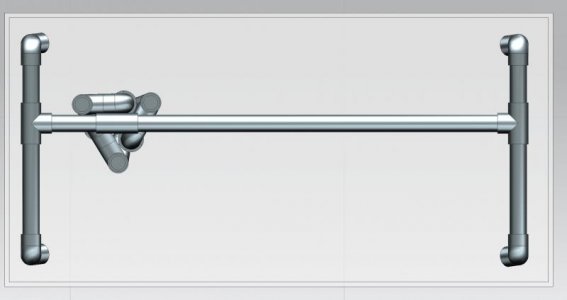

Soon i will get some CAD models together to start virtually building.

Anyone know where i can find a tank of roughly these dimensions for a good price? Acrylic or Glass? If Glass what kind?

Thanks folks! Really looking forward to this adventure