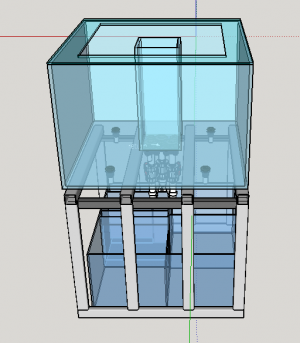

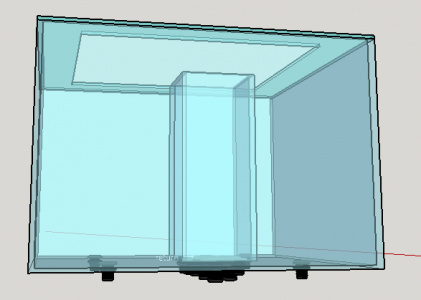

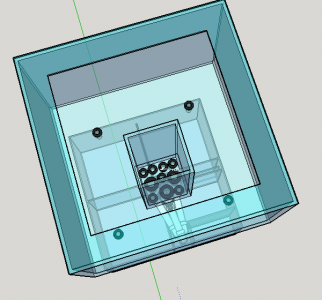

Hey guys! Long time lurker, first time poster. I currently have a 55g tank that was set up as a trial run. Its been ten months, and I'm finally happy with how everything is doing. Time to upgrade. The plan is a 290 gallon, 47.5" x 47.5" x 32" display out of 3/4" acrylic for the sides, 1/2" for the top (6" eurobracing) and bottom. The sump will be about 90 gallons, out of 3/8". I plan on running a bean animal central overflow and four separate closed loop systems. (A priority for the tank is an equipment-free look from all four sides.) Rock work will surround the overflow box, breaching the surface (also covering the light cords running through PVC within the overflow), and there will be four little rock islands covering the closed loop locline in each corner of the tank. The overflow is off center to provide a different viewing experience from each side of the tank. I am hoping some of the more experienced reefers and builders on the forum might spend a couple minutes looking over what I've got planned before I start making a mess. The attached images are still a work in progress, but I figured there's enough there to give a general idea. I apologize for inevitably referencing an image that only exists in my head.

Questions for acrylic tank builders:

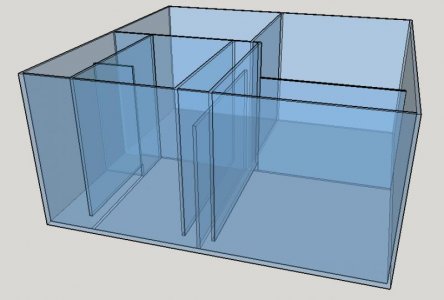

The attached image of the sump does not include a top brace. I intend to make covers for each compartment to manage humidity in the stand, so a top makes sense regardless, but I'm unsure how much top bracing is necessary. The water level will be from 18" to 15" down to 10" or so, and although the full width of the sump will be ~42", the largest compartment by volume is half that, square (which will be the top off reservoir).

I want to be sure 3/8" is adequate for the sump, and that 3/4" is adequate for the display. I was planning on a 6" perimeter brace and perhaps doing a cross center brace, essentially just cutting four access holes (off centered for the overflow), however I'm tempted to go up to 1" if it means I can do just a perimeter brace, as cross braces would make light placement more challenging.

I"ll use weldon 4 for the sump, but I want to miter the corners of the display and use weldon 40. Please someone talk me out of it.

Questions for sump experts:

Flow should be pretty obvious from the image. The three drain pipes will terminate an inch below water level. (Should I move the emergency standpipe to the return? Not sure if its worth the plumbing headache considering for closed loops). Water then travels over filter socks (which I may or may not like), under a baffle, into the skimmer chamber, under two more baffles, into the refugium (rock rubble and chaeto), then to the return. The far side of the tank is just the ATO. I've never seen a sump make a turn quite like this; could it have any negative effects I'm not seeing?

I plan on using a Reef Octopus Regal 200-INT DC skimmer. Adequate?

The return pump will be a Jebao dc12000, off of which I'll have a manifold running carbon and GFO through two separate BRS reactors, as well as space for future equipment additions. I'm uneasy about using a jebao pump, but I'll have backups and if I see what seems like premature failure, I'll upgrade. Still with me?

Questions for people who aren't crazy:

So I don't want powerheads on the glass, but I want flow control. I want to run four separate closed loop systems, each with its own Jebao dc12000 (remember those backups?). They can't be run externally, both because of heat and because they are apparently somewhat leaky, which is why my return chamber is so big. I want to plumb them closed, but still sitting in the return chamber for heat exchange and to prevent a wet floor. A. Am I going to be adding too much heat to the tank to function without a chiller? B. Am I crazy?

Questions for tech lovers:

Three cobalt 200w neotherms, Tunze auto top off. I'll also use an Apex controller, PM2 module, leak detection, an additional led and pumps control module and maybe their DOS pump for two part. Two variable 0-10 ports would control the four closed loop pumps, the return pump requiring an additional variable port. Make sense?

I'm really torn on lighting. I think I've decided on the 12x LED assemblies from Reef LED Lab. I want the full spectrum adjustability that 7 independent channels provide, but I know very little about the company or product. I'd do about eight assemblies, requiring five or so drivers and totaling something like 140w. Does anybody have experience with them?

Questions for engineers:

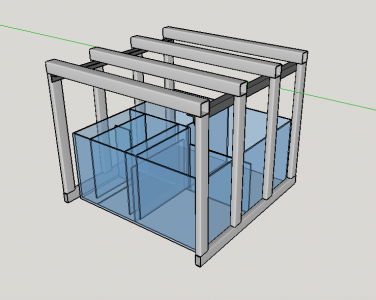

Anybody wanna go over my deflection calculations? The stand will be built out of .120 A500 mild steel. The posts are 1.5" x 3", the beams are 3" x 3". The stand has to be welded together in three separate sections in order to fit through my front door, so the design has the beams resting on top of the posts, the angle welded to the posts, and the angle bolted to the beams. My primary concern with this is racking. The facade of the stand will be 3/4" walnut ply, with an opening for a removable door cut out of a single piece, much like how you would cut the center out of a eurobraced top. I believe this is a good solution for the potential rack bracing issue. Thoughts?

Questions for woodworkers:

Normally I spray a post-catalyzed conversion varnish (ML Campell Krystal) as a topcoat. I'm worried that the high humidity conditions on the inside of the stand will cause issues. Is there a sealer or topcoat that is normally used or that works well in these conditions?

Anybody still reading? Anyway, I'm sure I've forgotten something, call me out on it. Any feedback is appreciated. I've learned an immense amount from lurking on reef central, and I want to thank to community that has helped empty my bank account.

NyxMaven

Questions for acrylic tank builders:

The attached image of the sump does not include a top brace. I intend to make covers for each compartment to manage humidity in the stand, so a top makes sense regardless, but I'm unsure how much top bracing is necessary. The water level will be from 18" to 15" down to 10" or so, and although the full width of the sump will be ~42", the largest compartment by volume is half that, square (which will be the top off reservoir).

I want to be sure 3/8" is adequate for the sump, and that 3/4" is adequate for the display. I was planning on a 6" perimeter brace and perhaps doing a cross center brace, essentially just cutting four access holes (off centered for the overflow), however I'm tempted to go up to 1" if it means I can do just a perimeter brace, as cross braces would make light placement more challenging.

I"ll use weldon 4 for the sump, but I want to miter the corners of the display and use weldon 40. Please someone talk me out of it.

Questions for sump experts:

Flow should be pretty obvious from the image. The three drain pipes will terminate an inch below water level. (Should I move the emergency standpipe to the return? Not sure if its worth the plumbing headache considering for closed loops). Water then travels over filter socks (which I may or may not like), under a baffle, into the skimmer chamber, under two more baffles, into the refugium (rock rubble and chaeto), then to the return. The far side of the tank is just the ATO. I've never seen a sump make a turn quite like this; could it have any negative effects I'm not seeing?

I plan on using a Reef Octopus Regal 200-INT DC skimmer. Adequate?

The return pump will be a Jebao dc12000, off of which I'll have a manifold running carbon and GFO through two separate BRS reactors, as well as space for future equipment additions. I'm uneasy about using a jebao pump, but I'll have backups and if I see what seems like premature failure, I'll upgrade. Still with me?

Questions for people who aren't crazy:

So I don't want powerheads on the glass, but I want flow control. I want to run four separate closed loop systems, each with its own Jebao dc12000 (remember those backups?). They can't be run externally, both because of heat and because they are apparently somewhat leaky, which is why my return chamber is so big. I want to plumb them closed, but still sitting in the return chamber for heat exchange and to prevent a wet floor. A. Am I going to be adding too much heat to the tank to function without a chiller? B. Am I crazy?

Questions for tech lovers:

Three cobalt 200w neotherms, Tunze auto top off. I'll also use an Apex controller, PM2 module, leak detection, an additional led and pumps control module and maybe their DOS pump for two part. Two variable 0-10 ports would control the four closed loop pumps, the return pump requiring an additional variable port. Make sense?

I'm really torn on lighting. I think I've decided on the 12x LED assemblies from Reef LED Lab. I want the full spectrum adjustability that 7 independent channels provide, but I know very little about the company or product. I'd do about eight assemblies, requiring five or so drivers and totaling something like 140w. Does anybody have experience with them?

Questions for engineers:

Anybody wanna go over my deflection calculations? The stand will be built out of .120 A500 mild steel. The posts are 1.5" x 3", the beams are 3" x 3". The stand has to be welded together in three separate sections in order to fit through my front door, so the design has the beams resting on top of the posts, the angle welded to the posts, and the angle bolted to the beams. My primary concern with this is racking. The facade of the stand will be 3/4" walnut ply, with an opening for a removable door cut out of a single piece, much like how you would cut the center out of a eurobraced top. I believe this is a good solution for the potential rack bracing issue. Thoughts?

Questions for woodworkers:

Normally I spray a post-catalyzed conversion varnish (ML Campell Krystal) as a topcoat. I'm worried that the high humidity conditions on the inside of the stand will cause issues. Is there a sealer or topcoat that is normally used or that works well in these conditions?

Anybody still reading? Anyway, I'm sure I've forgotten something, call me out on it. Any feedback is appreciated. I've learned an immense amount from lurking on reef central, and I want to thank to community that has helped empty my bank account.

NyxMaven