mcozad829

Premium Member

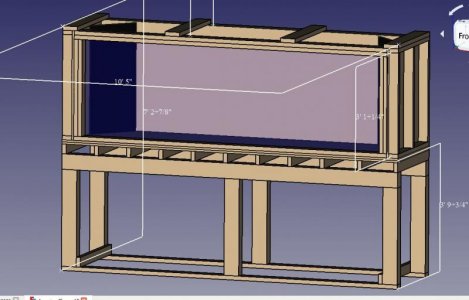

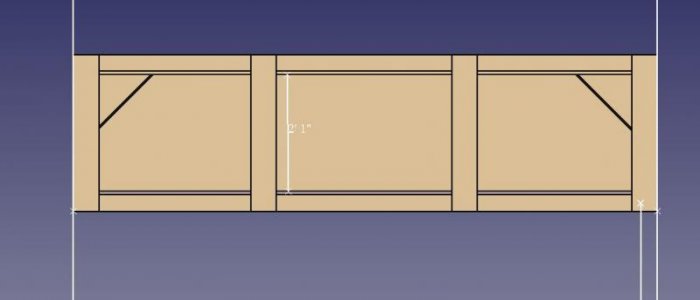

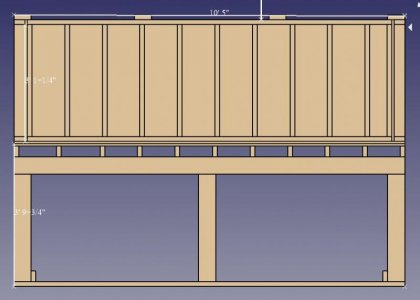

I am planning on getting back into saltwater after a few years away and have decided to go big. I am a DIY guy and hate paying labor for things that I can do myself. I am completely confident in my abilities to build a strong tank design and have it waterproof for many years to come. That being said I am always looking for flaws in my designs and would love some help. This is my first CAD draft of the structural support for this build which is basically tank and stand. If you don't mind taking a look at it and offering some constructive criticism I would appreciate it. Here is a little info behind the project.

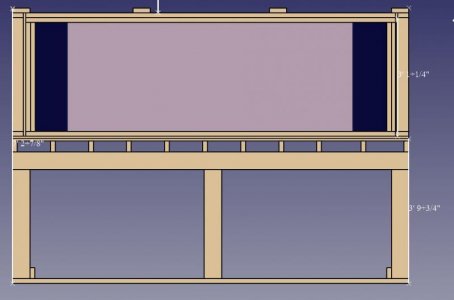

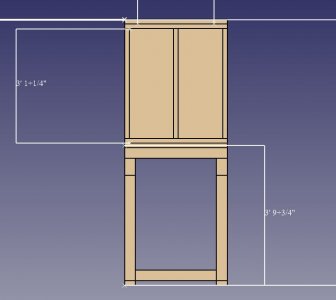

This tank is going along the back wall of my home office, the width of the back wall is 126". The exterior frame of the tank is 125", allowing a small margin of error while I will still be able to achieve a built in look with the proper finishing trim work.

As currently designed the tank will be approximately 460 Gallons with internal dimensions of 116.5L X 25W X 37H. This is going to be a FOWLR show tank. I unfortunately cannot go any wider with dimensions because my home office is used as a second guest room and I have to leave room for other furniture.

Any questions, comments or tips for this process are appreciated.

Also if you use free cad and want the actual .fcstd file to look over just PM me and I would be happy to email it.

Thank You

This tank is going along the back wall of my home office, the width of the back wall is 126". The exterior frame of the tank is 125", allowing a small margin of error while I will still be able to achieve a built in look with the proper finishing trim work.

As currently designed the tank will be approximately 460 Gallons with internal dimensions of 116.5L X 25W X 37H. This is going to be a FOWLR show tank. I unfortunately cannot go any wider with dimensions because my home office is used as a second guest room and I have to leave room for other furniture.

Any questions, comments or tips for this process are appreciated.

Also if you use free cad and want the actual .fcstd file to look over just PM me and I would be happy to email it.

Thank You