You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

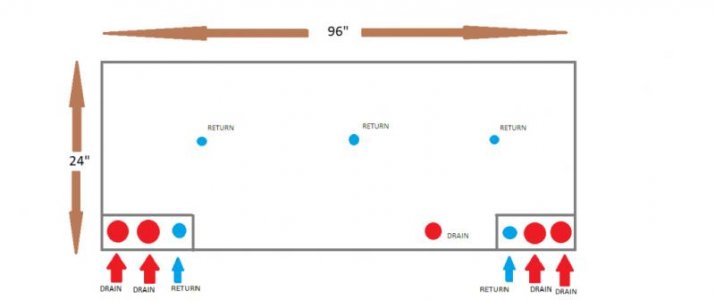

96x24x25 Closed loop help.

- Thread starter Dr. Reef

- Start date

d3hree

New member

is there just one drain feeding the CLS?..if so i would be tempted to add another especially in a tank of your size, but having two for redundancy is always a good idea.

Is it 2 x twin durso's?...are the syphons and dursos joined under the tank...or do they dump seperately into the sump?

Is it 2 x twin durso's?...are the syphons and dursos joined under the tank...or do they dump seperately into the sump?

If your returns are in the bottom of your tank I would think about rock placement and maybe have them closer to the front of the glass to give you more room for the rocks.

Are you using an OM? You only have 3 returns? I would go with 4 for sure if not more. If you use one inlet I would split it into two with a T fitting and two strainers on the end.

Maik1

Are you using an OM? You only have 3 returns? I would go with 4 for sure if not more. If you use one inlet I would split it into two with a T fitting and two strainers on the end.

Maik1

i am not very familiar with terms used. but each over flow in corner has 2 drains and 1 return. each over flow will have 2x 1.5" drains going to a 3" pvc that dumps into the sump into a sock. so goes for the other side(overflow) so 2 socks and 2 3" pvc. Closed loop is only fed by a 1.5" drain located towards the back and returned by the 3x 1" returns in the center of the tank.

i hope i described it properly.

regular over flow returns are run by super dart pump 4000gph at that height.

CL is run by dart 3600gph at that hight.

i hope i described it properly.

regular over flow returns are run by super dart pump 4000gph at that height.

CL is run by dart 3600gph at that hight.

Why not go over the top of the tank with the CLS pipe work this will allow you to hide the return pipes under the sand and in rock work also meaning you will not have to drill so many holes in the tank

A very nice tank that belongs to Stewart Bertram from D-D uses this system to very good effect heres a couple of images of the basic set up

Closed Loop Pipework

Closed Loop Pumps

If you do decide to go with tyhe drilling of the tank for the CLS i would think about putting the drain for the cls in the back of the tank and not through the base.

A very nice tank that belongs to Stewart Bertram from D-D uses this system to very good effect heres a couple of images of the basic set up

Closed Loop Pipework

Closed Loop Pumps

If you do decide to go with tyhe drilling of the tank for the CLS i would think about putting the drain for the cls in the back of the tank and not through the base.

Honestly i have no idea what i am doing. thats why i started this thread so i would get info and then make changes accordingly before i order the tank. most of the setups of larger tanks i have seen here on reef central they have usually 2-4 returns in front of the tank for CL. i put the 3 hols in middle of the tanks coz i was gonna split them into a T and direct flow in front and back.

Last edited:

dave.m

Active member

Well, I don't mean to sound harsh or offensive, but considering the tens of thousands of dollars you are going to eventually be pouring into this hobby, I think it might be worth your while investing in some books on the subject. I would start off with The Reef Aquarium, Volumes 1, 2 and 3, by Charles Delbeek and Julian Sprung. They are not the most recent of books (all books in this hobby quickly fall behind current technologies) but they will give you a good grounding in all aspects of reef aquariums, especially Volume 3 for design and set-up.

HTH

Dave.M

HTH

Dave.M

Have a look at page 4 of the attached PDF http://www.theaquariumsolution.com/technical-review-david-saxbys-reef-aquarium-chris-carlton

Ok the tank maybe a lot bigger than you are going for and as its an L shape it gets a little more complicated but it also shows a good plan for a CLS system that works very very well

Ok the tank maybe a lot bigger than you are going for and as its an L shape it gets a little more complicated but it also shows a good plan for a CLS system that works very very well

prop-frags

SPS Slave

There is a ton of good info on here about CL and flow design.

Take a look at this thread for some links to good examples.

You're on the right track. Be patient and keep reading. :reading:

Include your rock placement in your design, so that you can then incorporate the CL outlets into that. It is really valuable to use CL outlets to direct flow around and through your rock structures. This will help keep detritus from building up on your rocks, and promote healthy corals.

Another important flow design element is keeping detritus from settling into the bottom of the tank. Some folks work on a flow pattern that creates a "rolling wave" across the bottom of the tank, upwards, then into the overflow down to the sump/skimmer.

Take a look at this thread for some links to good examples.

You're on the right track. Be patient and keep reading. :reading:

Include your rock placement in your design, so that you can then incorporate the CL outlets into that. It is really valuable to use CL outlets to direct flow around and through your rock structures. This will help keep detritus from building up on your rocks, and promote healthy corals.

Another important flow design element is keeping detritus from settling into the bottom of the tank. Some folks work on a flow pattern that creates a "rolling wave" across the bottom of the tank, upwards, then into the overflow down to the sump/skimmer.

Ldagger

New member

simpler can be better

simpler can be better

I had this exact setup on my 500 gallon for about 5 years. I worked well but was a pain. Having so many holes in bottom of the tank means you have to look for leaks on bulkheads all the time and it's something to worry about.

So if you are putting your tank somewhere - where you don't want the floor wet ever, than I would take a different approach. I think most people really misunderstand what a close loop should be imo. I would suggest instead of trying to create a jazzcui- you should just do a true closed loop where the water goes from on side the the tank to the other from low to high. Remember on a real reef you get volume flow and not shear flow. If you place your intake pipe over the back and up high on one end of the tank, and you one return over the back and very low on the other side of your tank this ensures the total amount of your pump water travels the length of your tank. It makes the loop. This is an efficient simple design- no bulkheads, simple piping, and it would be easy to remove or add too. You could keep the 2 overflows with 2 holes in the bottom of each. Use 1 drain on each side and 1 return on one side. Have extra hole for emergency drain. So that would be 3 drains, and one return, all inside the overflow which means your whole tank volume cannot drain. I would think hard about putting holes in the middle bottom of my tank- if a plastic bulkhead broke you would lose all the water in the tank in a short amount of time. For turbulent flow go with any prop pump(s) out there. Also this is an opinion but I do not think you need a large amount of water going into your sump and back, it makes more noise and does not provide so much benefit, a moderate flow or modest is all that is required. Food for thought and this is just my experince. remember getting holes drilled, piping, bulkheads, all add up in costs, money that could go toward prop type pumps, and they are all sources of failure. bad failures at that. good luck

simpler can be better

I had this exact setup on my 500 gallon for about 5 years. I worked well but was a pain. Having so many holes in bottom of the tank means you have to look for leaks on bulkheads all the time and it's something to worry about.

So if you are putting your tank somewhere - where you don't want the floor wet ever, than I would take a different approach. I think most people really misunderstand what a close loop should be imo. I would suggest instead of trying to create a jazzcui- you should just do a true closed loop where the water goes from on side the the tank to the other from low to high. Remember on a real reef you get volume flow and not shear flow. If you place your intake pipe over the back and up high on one end of the tank, and you one return over the back and very low on the other side of your tank this ensures the total amount of your pump water travels the length of your tank. It makes the loop. This is an efficient simple design- no bulkheads, simple piping, and it would be easy to remove or add too. You could keep the 2 overflows with 2 holes in the bottom of each. Use 1 drain on each side and 1 return on one side. Have extra hole for emergency drain. So that would be 3 drains, and one return, all inside the overflow which means your whole tank volume cannot drain. I would think hard about putting holes in the middle bottom of my tank- if a plastic bulkhead broke you would lose all the water in the tank in a short amount of time. For turbulent flow go with any prop pump(s) out there. Also this is an opinion but I do not think you need a large amount of water going into your sump and back, it makes more noise and does not provide so much benefit, a moderate flow or modest is all that is required. Food for thought and this is just my experince. remember getting holes drilled, piping, bulkheads, all add up in costs, money that could go toward prop type pumps, and they are all sources of failure. bad failures at that. good luck

Zoney I don't see anything showing a description???

theres a black and green part of the page with dave saxbys reef picture 2009 on it click on that and then the 4th page down theres a picture of the CLS pipe work and a bit of text to go with it . The pdf is to big for me to upload directly to the forum

Ldagger you have made me change my mind. in good sense. you are right, these are holes in bottom of the tank that means leaks or bulkhead failure will empty the whole tank out in no time. i can care less if floor gets wet as my tank in in wall and the tank side is in the garage but livestock will not survive as i am not home 12 hrs a day. i am rethinking my approach on CL.i think over the back drain and return sounds much better and leak/failure proof.

Ldagger

New member

I think you will be happier. Less to worry about and less complicated plumbing.

Better to worry about feeding your corals Since it's in your garage, home depot online sells a kit to insulate your garage door. It would save you alot of money in the long run, and maybe your fish in July and Jan. Also a 12 dollar floor flood alarm is worth the investment. It will tell you if there is a real problem if you are asleep in bed. I am setting up a 240 gal in my basement right now, I need to update my thread (it's way old) and give some pics. It's 8' long, 2' high.

Since it's in your garage, home depot online sells a kit to insulate your garage door. It would save you alot of money in the long run, and maybe your fish in July and Jan. Also a 12 dollar floor flood alarm is worth the investment. It will tell you if there is a real problem if you are asleep in bed. I am setting up a 240 gal in my basement right now, I need to update my thread (it's way old) and give some pics. It's 8' long, 2' high.

Better to worry about feeding your corals

Ldagger

New member

Also you need to be concerned about humidity. Not to be a buzz kill here. If tank were in your house, your hvac would probably take care of it, in garage if you don't have something setup to deal with it, then it will be a problem. It will rust your tools : ) I would definiately get some type to system to get water/damp air out of your garage. I do not know your garage setup, but it may be easy to put in a skylight that can open. mightbe difficult since tank would be against an interior wall to get light to it. just an idea.

my garage is insulated. i have AI leds now so heat is not as bad, also got a jbj 1/2 hp chiller on it. at most the temp reaches 81F during real hot days like 103F+ usually right at 78-80 range. now humidity is a problem. tools are already rusted. it is a three car garage so i have a lot of room but i need to install a window unit or mini split just to keep air circulating.

Similar threads

- Replies

- 10

- Views

- 1K