Ryan,

For the most part, using WO40 because it is "stronger" is waaaay past the point of diminishing returns. Even WO4 is good to something like 2500psi which is far greater than we will ever see in these tanks.

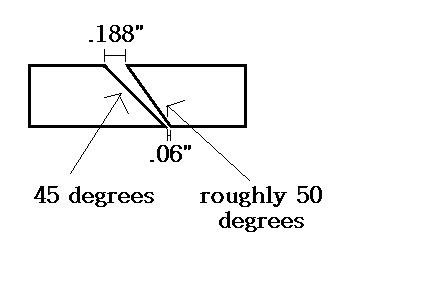

I don't go into placing the slight chamfer here (or 40 for that matter) because A) *very* few are going to do it and B) for most practical purposes it's not the normal method that most would use to build tanks, sumps, etc. it requires more tooling than most hobbyists are going to use so teach the simplest method that most would be comfortable with.

FWIW, a WO40 "joint" is strong, no doubt, but that does not translate into "bite" into acrylic. Put it this way, you can make a beautiful WO 40 "joint" between 2 pieces of steel, you can pull the pieces apart very easily since the 40 doesn't actually bite into the steel yet the joint itself may be very strong, get my meaning?

There are other reasons and esp why mfrs recommend 40 which is another story but hopefully this is a start

James