You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acrylic fabrication questions? I can help!

- Thread starter JohnL

- Start date

Floyd R Turbo

Either busy or sleeping

Got a quick question. I have a buddy who has a 48 x 12 x 6 deep frag tank that he has used for a while, it is bowing out about 3/4" in the middle (the ends are 12" wide, the middle bows out 3/8" in either direction)

He got some 3/8" strips of acrylic made to fit the original inner dimension of the tank, so he was going to pull the front/back panel back together with clamps and weld the cross bar in place with the ends of it attached to the inside of the front and back panel. He has 4 braces but was just going to put 2 in at 18" from either end.

Is this a good idea or will it induce 'reverse stress' and lead to a failure at the bottom joint down the line?

He got some 3/8" strips of acrylic made to fit the original inner dimension of the tank, so he was going to pull the front/back panel back together with clamps and weld the cross bar in place with the ends of it attached to the inside of the front and back panel. He has 4 braces but was just going to put 2 in at 18" from either end.

Is this a good idea or will it induce 'reverse stress' and lead to a failure at the bottom joint down the line?

Floyd R Turbo

Either busy or sleeping

Also the tank is currently empty, but only temporarily...

DustinB

New member

I don't know if this helps with more info, but this was the sales lady's reply. She said it comes from Atofina.

Hi, Here is what I have ,

ACRYLIC SHEET GENERAL PURPOSE 0.354 IN THK 48 IN WIDE 96 IN LONG CLEAR CAST PAPER S828677

IMO 3 days is just fine, and yes - it does change with thickness and if the joints are cast or solvent bonded. 2"+ can take several weeks to fully cure as there is simply so much more in solution within the joint. In the shop, I simply don't ship something unless it sits here for at least a week post-production. Large tanks may sit for months (we do those firstJames, do you have a 'standard' for how long you wait to fill a tank/sump with water (for use)? Longer for thicker material? Based on joint technique (solvent vs 40/42)?

How long for this sump that I just got done: All 3/8" Plex-G, MC/10%AA solvent joints, 1/4" bottom

If it is Plex-G - it will have an inspection sticker if masked in plain brown paper. The material is fine, I've had no issues. "General purpose" is generally any cast product, or at least that's the case around these parts.Hey guys, I've been trying to track down some decent material locally for a decent price. Most everyone wants to charge me freight for Plexi-G or Polycast, they only stock no name. I did find one place that had great pricing on something I am unsure about.

It is unmarked brown paper masking, but, she said their invoice shows "Atofina - General Purpose". From what I read in this thread, Atofina is the same place that makes Plexi-G. Any ideas if this could be unmarked Plexi-G or any idea what it could be? It has a better price than Acrylite GP.

FWIW I'm getting the printed stuff now at the same price

you may also wish to contact Port Plastics in Dallas at 817-834-7678 as they have been real good about keeping Polycast in stock and do frequent branch transfers..

HTH,

James

Floyd R Turbo

Either busy or sleeping

Sure, it's about 36 x 17 x 12 (outer dims). The center divider is 22 x 11, then the first baffle is at 10" from the end and 6" tall, next one is 6" tall and 6" away from the first and I think 2" off the bottom (maybe 3 - I made a last minute decision on placement), then next is 5" tall and 3" from the 2nd baffle.

I was just in the LFS getting a heater but forgot my camera. They raided their 600 and split the corals between the 1500 and the pond (1700 gallons, I'm guessing) and it looks killer. The 600 had a leather that was 36" in diameter (in the pond now) and a brain that was about 24" (in the 1500 now).

I was just in the LFS getting a heater but forgot my camera. They raided their 600 and split the corals between the 1500 and the pond (1700 gallons, I'm guessing) and it looks killer. The 600 had a leather that was 36" in diameter (in the pond now) and a brain that was about 24" (in the 1500 now).

To my knowledge, there are no "stores" that sell decent acrylic in the area. You'll have to get it through a distributor such as Port Plastics or Laird Plastics. There are others, to be sure, but no "stores" that I know of..Does anyone have any stores here in the San Francisco bay area where I can buy the good acrylic?

Side note, was just down there for a week, wish I had known

James

Floyd R Turbo

Either busy or sleeping

Sean, it depends on your application. For tanks, cell cast only and Plexiglas-G and Polycast are the only ones that James has recommended for use. I don't think Lucite is anything you want to use, not sure on that one though.

For sumps and the like, you could probably get away with a good quality extruded like Plexiglas-MC or Acrylite-FF. Extruded just has a higher propensity to craze and bow, but for most hobbyist level applications, should do just fine from what I understand.

I'm not 100% sure on the Acrylite-FF because Acrylite-GP has gone by the wayside a bit according to James (I quoted him on this recently, GP needs further testing, the <1" thick stuff is made in China, 1" and over is made in Germany and he doesn't use it for export reasons)

On this subject, I talked to a tech guy at Arkema (makers of Plexiglas) and there are 2 different grades of Cell Cast material: Plexiglas-G (paper mask, print on one side) and a "General Purpose" cell cast (paper mask, no print). These are both the exact same material, exact same process, the difference is that the "General Purpose" material is a lower 'grade' material, in that it may have some black specs, it may not have "G" grade clarity, there may be a bubble within the material, or there may be variations out of "G" grade tolerances in the thickness of the material (either overall or from one area of the sheet to another).

Think about it this way: most multiple-core AMD computer processors, such a dual core for example, are actually have more processor cores on the chip, but one or more of the cores did not pass standards, so they just disable those cores, which is why you can "unlock" them if you have the right motherboard. It's cheaper to do this than to create 2 separate lines of production.

Similarly, instead of making a "G" grade and a "General" grade, they just make it all and then set aside the best quality material and call it "G". G material also comes with a guarantee, so if you make a tank from it and pull off the masking and find a problem with the material, they will cover it (supposedly). However my supplier mentioned to me that once you cut and bond it, the warranty is gone, so I don't know who is right there.

Anyways, the "General Purpose" Plexiglas Cell Cast is about 25% cheaper, I've been using the 3/8" stuff recently to build sumps and it looks fine to me.

For sumps and the like, you could probably get away with a good quality extruded like Plexiglas-MC or Acrylite-FF. Extruded just has a higher propensity to craze and bow, but for most hobbyist level applications, should do just fine from what I understand.

I'm not 100% sure on the Acrylite-FF because Acrylite-GP has gone by the wayside a bit according to James (I quoted him on this recently, GP needs further testing, the <1" thick stuff is made in China, 1" and over is made in Germany and he doesn't use it for export reasons)

On this subject, I talked to a tech guy at Arkema (makers of Plexiglas) and there are 2 different grades of Cell Cast material: Plexiglas-G (paper mask, print on one side) and a "General Purpose" cell cast (paper mask, no print). These are both the exact same material, exact same process, the difference is that the "General Purpose" material is a lower 'grade' material, in that it may have some black specs, it may not have "G" grade clarity, there may be a bubble within the material, or there may be variations out of "G" grade tolerances in the thickness of the material (either overall or from one area of the sheet to another).

Think about it this way: most multiple-core AMD computer processors, such a dual core for example, are actually have more processor cores on the chip, but one or more of the cores did not pass standards, so they just disable those cores, which is why you can "unlock" them if you have the right motherboard. It's cheaper to do this than to create 2 separate lines of production.

Similarly, instead of making a "G" grade and a "General" grade, they just make it all and then set aside the best quality material and call it "G". G material also comes with a guarantee, so if you make a tank from it and pull off the masking and find a problem with the material, they will cover it (supposedly). However my supplier mentioned to me that once you cut and bond it, the warranty is gone, so I don't know who is right there.

Anyways, the "General Purpose" Plexiglas Cell Cast is about 25% cheaper, I've been using the 3/8" stuff recently to build sumps and it looks fine to me.

Floyd R Turbo

Either busy or sleeping

So is your plan to cut a slot on the end of the tank, then attach the boxes to either side of the panel?

Is the tank new or used?

Is the tank new or used?

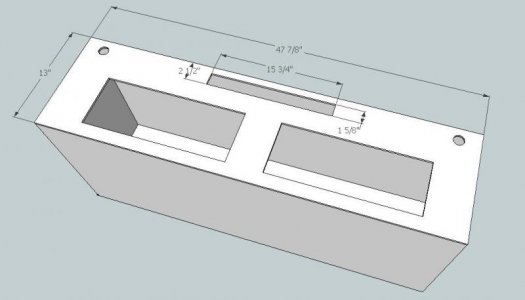

The tank is used. I was thinking of doing it in the back center of the tank. I'm not quite sure if I want to do a slot or punch a few holes to allow water to flow from the inside weir to the external overflow. In the external overflow, I will be adding the "bean animal" style plumbing. I've attached a picture showing how the top brace of the tank looks.

Attachments

Floyd R Turbo

Either busy or sleeping

Big Bean fan...the glass tank I just got has that, haven't fired it up yet.

As far as acrylic goes, IMO, a hole will weaken a tank much less than a slot. A slot basically disconnects the panel from the top eurobrace, and thus must have additional (structural) bracing added to compensate.

Considering that you can put a few holes along the back and space them apart adequately without weakening the tank that much, I would go that route.

The reason I asked if the tank was new or used is that a used tank has material that has already been stressed during use. This means that you will have to make sure the back panel is nice and flat when joining the box, and this might be difficult. The other option is to just make boxes and hold them on with bulkheads through the holes. In that case, I would make both out of 3/8" General Purpose Plexiglas, should be nice and solid.

As far as acrylic goes, IMO, a hole will weaken a tank much less than a slot. A slot basically disconnects the panel from the top eurobrace, and thus must have additional (structural) bracing added to compensate.

Considering that you can put a few holes along the back and space them apart adequately without weakening the tank that much, I would go that route.

The reason I asked if the tank was new or used is that a used tank has material that has already been stressed during use. This means that you will have to make sure the back panel is nice and flat when joining the box, and this might be difficult. The other option is to just make boxes and hold them on with bulkheads through the holes. In that case, I would make both out of 3/8" General Purpose Plexiglas, should be nice and solid.

Floyd R Turbo

Either busy or sleeping

dang double post. I didn't even click it twice what's up man

Last edited:

Floyd R Turbo

Either busy or sleeping

Probably will be OK. It's more about your technique that makes it tricky than the material IMO - how well you prep the edge of the material and flatten the tank panel before you bond it, etc.

Plus you want to make sure the tank has been empty for a few months. If you were to drain the tank and try this, you might end up with some crazing. The material needs to let out the water it has absorbed. It will also return closer to it's original shape and will be easier to flatten.

Plus you want to make sure the tank has been empty for a few months. If you were to drain the tank and try this, you might end up with some crazing. The material needs to let out the water it has absorbed. It will also return closer to it's original shape and will be easier to flatten.

Similar threads

- Replies

- 2

- Views

- 721

- Replies

- 2

- Views

- 299

- Replies

- 12

- Views

- 2K