You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acrylic fabrication questions? I can help!

- Thread starter JohnL

- Start date

troylee

In Memoriam

1" acrylic will be fine for a rimless...James

Could you give a suggestion on acrylics thickness on 24"*24"*24" open tank?

thanks.

henrystyle

Member

How do you calculate what acrylic thickness is needed for acrylic tank building?

Is there a certain formula to figure this out?

Is there a certain formula to figure this out?

Most 'round here would use #4Which weld on is prefered for constructing an aquarium?

There isn't "one" good formula - too many variables. For any specific deflection tolerance, size, and bracing scheme, you can derive a formula from Rourke's Formulas for Stress & Strain. But, you will have to know the necessary physical properties, some of which are not published and are kept "secret" by the acrylic mfrs.How do you calculate what acrylic thickness is needed for acrylic tank building?

Is there a certain formula to figure this out?

James

toddanddaneen

New member

Ok i've got a 110 gallon flat back hex that has 2 cracks roughly 3 inches long at the back center on either side of the overflow. I have already glued the cracks with weld on and it holds water but i'm still a little unsure of using it for an extended peroid of time. Is there a way to brace this up better so that it can be used safely?

henrystyle

Member

ok thanks.There isn't "one" good formula - too many variables. For any specific deflection tolerance, size, and bracing scheme, you can derive a formula from Rourke's Formulas for Stress & Strain. But, you will have to know the necessary physical properties, some of which are not published and are kept "secret" by the acrylic mfrs.

James

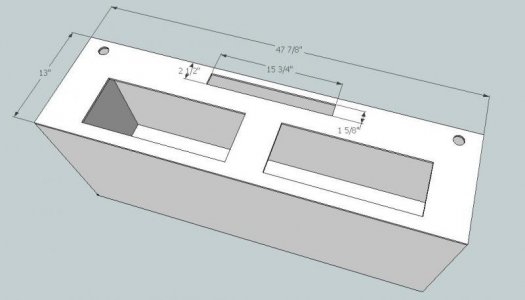

I want to make a slit across the back of my tank to act as the overflow to allow water to fall into an attached external overflow box. I read a several pages back Henrystlye was going to do this.

I was originally going to have a internal overflow box and make holes in the back where the water would flow into the external overflow box but was suggested to remove the internal overflow box and have a slit across the back.

My tank is 48" long 1/4" acrylic. I'm thinking I would like the slit to be 1/4" wide and maybe 24"-30" centered across the back. I would like to make the slit as close to the top as possible to prevent the water line being to low in the display tank. How do I go about making this slit? I would think I would use a router but, I don't have a router table.

I'm attaching a sketchup of my tank. I'm worried about the bracing and if it will weaken the tank.

I was originally going to have a internal overflow box and make holes in the back where the water would flow into the external overflow box but was suggested to remove the internal overflow box and have a slit across the back.

My tank is 48" long 1/4" acrylic. I'm thinking I would like the slit to be 1/4" wide and maybe 24"-30" centered across the back. I would like to make the slit as close to the top as possible to prevent the water line being to low in the display tank. How do I go about making this slit? I would think I would use a router but, I don't have a router table.

I'm attaching a sketchup of my tank. I'm worried about the bracing and if it will weaken the tank.

Attachments

henrystyle

Member

After I thought about it cutting a slot across the back would make the back of the tank bow. The top brace would only be attached to the top portion of the slot. Not good.

The only other option would be to cut teeth into the back panel of acrylic then add an external overflow box to make that plan work.

That should work in theory.

The only other option would be to cut teeth into the back panel of acrylic then add an external overflow box to make that plan work.

That should work in theory.

troylee

In Memoriam

I want to make a slit across the back of my tank to act as the overflow to allow water to fall into an attached external overflow box. I read a several pages back Henrystlye was going to do this.

I was originally going to have a internal overflow box and make holes in the back where the water would flow into the external overflow box but was suggested to remove the internal overflow box and have a slit across the back.

My tank is 48" long 1/4" acrylic. I'm thinking I would like the slit to be 1/4" wide and maybe 24"-30" centered across the back. I would like to make the slit as close to the top as possible to prevent the water line being to low in the display tank. How do I go about making this slit? I would think I would use a router but, I don't have a router table.

I'm attaching a sketchup of my tank. I'm worried about the bracing and if it will weaken the tank.

are you slitting the top like the sketch or just the back??? if you slit the back and use a external overflow box you will be fine....i do it almost everyday...

just make sure the overflow box is beefy to take the stress off the back i would suggest 3/8" acrylic and weld it on with weldon 3 or 4....

somethin like this...

chris.francis14

Member

I just filled my new truvu 90 gallon. 48 long 18 wide 24 tall. The center brace seems to bow down a little bit, how normal is this? Do I have anything to worrk about?

The tank is probably underbuilt a little so this would be expected, I'm guessing 3/8" material at most? In time however, it will start to bow up - nothing to worry about, just the material absorbing moisture and growing a littleI just filled my new truvu 90 gallon. 48 long 18 wide 24 tall. The center brace seems to bow down a little bit, how normal is this? Do I have anything to worry about?

HTH,

James

troylee

In Memoriam

If ya soak the joint it weakens the material around it... There's a fine line in there for perfect clear joints without excess stress being introduced... I know soaking a little longer allows for cleaner joints on pieces that weren't prepped properly " saw cuts" but it's better to not have all that excess ooze and unnessacary stress IMO. For a short cut... I'm sure James has different thoughts on this but that's mine...

Hi Chris,

Pretty mcuh agree with Troy on this. Unless we're doing thick stuff (1.5"+) I try to keep soak time under a minute. Solvents (and 40) work by means of chemically stressing the material, the shorter duration that is, the better, all other things being equal. One of the reasons I stress a smooth machined edge rather than a saw-cut edge.

Kreisels and similar tanks which are far more complicated and use far thicker materials, are a whole 'nuther creature You are conceivably doing a 50' joint in thick stuff so you have to adjust everything from the gaps you leave to the chemical make-up of the solvent to soak time, clamping, cure time, and so on.

You are conceivably doing a 50' joint in thick stuff so you have to adjust everything from the gaps you leave to the chemical make-up of the solvent to soak time, clamping, cure time, and so on.

James

Pretty mcuh agree with Troy on this. Unless we're doing thick stuff (1.5"+) I try to keep soak time under a minute. Solvents (and 40) work by means of chemically stressing the material, the shorter duration that is, the better, all other things being equal. One of the reasons I stress a smooth machined edge rather than a saw-cut edge.

Kreisels and similar tanks which are far more complicated and use far thicker materials, are a whole 'nuther creature

James

Similar threads

- Replies

- 2

- Views

- 736

- Replies

- 4

- Views

- 345

- Replies

- 12

- Views

- 2K