MeghanisradxD

New member

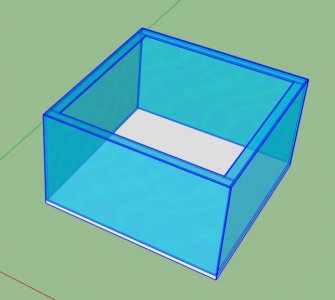

I'm entertaining the thought of building a 3.5' x 3.5' ish foot tank. I think it calculates out to around 180 gallons.

I've been doing a lot of reading and video watching, but I want to hear from those that have done it here. What went wrong? What went right? What would you have done different? Is it an absolutely terrible idea?

Lay it on me. Articles, videos, tips. Anything.

I'm looking at glass rather than acrylic and actually using a plywood bottom with a pond epoxy. Same concept as Joey (King of DIY) does in this video series. https://www.youtube.com/watch?v=2beOiIgBvUM

Thanks!

I've been doing a lot of reading and video watching, but I want to hear from those that have done it here. What went wrong? What went right? What would you have done different? Is it an absolutely terrible idea?

Lay it on me. Articles, videos, tips. Anything.

I'm looking at glass rather than acrylic and actually using a plywood bottom with a pond epoxy. Same concept as Joey (King of DIY) does in this video series. https://www.youtube.com/watch?v=2beOiIgBvUM

Thanks!