- Forum

- More Forums

- Reef Club Forums

- West Region-Reef Club Forums

- Greater San Francisco Bay Area Reef Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DivingTheWorld's Custom Leemar 80g Rimless Reef

- Thread starter DivingTheWorld

- Start date

DivingTheWorld

Active member

divingtheworld, where in san ramon are you located? I too am in San Ramon and I just got my new Leemar tank on Sunday. 96 x 26 x22. It came out extremely nice and I cant wait to get it up and running

We live in Windemere, out off Bollinger. Let me know if you need any help with your tank. I'd love to check it out.

Maximus

Active member

divingtheworld, where in san ramon are you located? I too am in San Ramon and I just got my new Leemar tank on Sunday. 96 x 26 x22. It came out extremely nice and I cant wait to get it up and running

Did you buy yours from Robert? If so, I have seen it and it is nice!

DivingTheWorld

Active member

I'm starting to draw up my stand now. It will be a basic 2x4 stand skinned with something nice and stained. This will be my first attempt at a decent quality stand, so we'll see how it goes...

DivingTheWorld

Active member

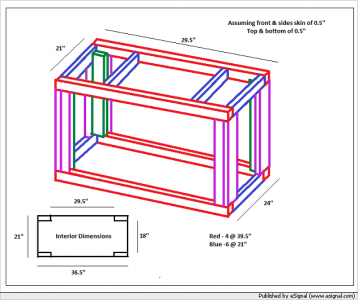

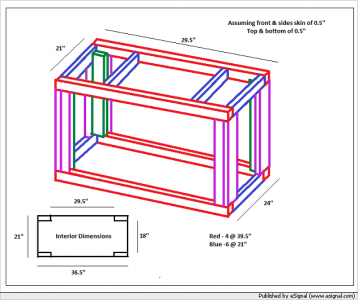

Ok, here's my first design attempt on a stand. This is just for the framework and does not include skin. I plan top and bottom of 1/2" plywood with sides skinned by 1/2" nice stain-able wood.

The inside will be sealed with silicone and painted with some type of waterproof paint. My goal is for the inside base to be a catch basin should the sump flood for some reason...

There will be either two main doors on the front or one giant panel with magnets to hold it on. Both sides will have doors. Left side will be to access ATO and/or Dosing while the right side will have a panel to mount electronics.

This should allow for 40.5" x 24.5" with 1/4" on each side. Too much, too little?

Please feel free to critique!

The inside will be sealed with silicone and painted with some type of waterproof paint. My goal is for the inside base to be a catch basin should the sump flood for some reason...

There will be either two main doors on the front or one giant panel with magnets to hold it on. Both sides will have doors. Left side will be to access ATO and/or Dosing while the right side will have a panel to mount electronics.

This should allow for 40.5" x 24.5" with 1/4" on each side. Too much, too little?

Please feel free to critique!

DivingTheWorld

Active member

Well, I decided to make the stand 34" high. I took some measurements and decided that I could reach my hand over the side and work in the aquarium at that height. Any higher and I'd need a step ladder.

I picked up a bunch of 2x4's to start framing. I checked several lumber dealers and found that Lowes had the straightest and most dry wood. I made the pink and green cuts. I'm still deciding on the exact length and width.

Checking several dealers for the "skin" leaves me with two options. I can go with veneered plywood which is in either 1/2" or 3/4". Or...I can go with 3/4" solid wood boards. I'm kinda leaning towards the boards, although that will reduce my interior dimensions by 1/2" each direction and I'm already tight on space.

I know I don't want to skin in Pine or Oak. Anyone have any suggestions on what type of wood to use? I'd like the finished product to be stained dark.

I picked up a bunch of 2x4's to start framing. I checked several lumber dealers and found that Lowes had the straightest and most dry wood. I made the pink and green cuts. I'm still deciding on the exact length and width.

Checking several dealers for the "skin" leaves me with two options. I can go with veneered plywood which is in either 1/2" or 3/4". Or...I can go with 3/4" solid wood boards. I'm kinda leaning towards the boards, although that will reduce my interior dimensions by 1/2" each direction and I'm already tight on space.

I know I don't want to skin in Pine or Oak. Anyone have any suggestions on what type of wood to use? I'd like the finished product to be stained dark.

DivingTheWorld

Active member

I did some investigating of the furniture in our family room where the aquarium is going. The manufacturer just writes, "Selected Hard Woods" and the finish as "Dark Rustic". Not very helpful... They have another furniture line which looks very similar and with those they say the wood is "Cherry Veneer" with a finish as "Burnished Brown".

So...I think the go to may be Cherry with a brownish finish. More investigating needed...

So...I think the go to may be Cherry with a brownish finish. More investigating needed...

DivingTheWorld

Active member

Wow, good timing with all these Black Friday sales. Ordered my sump, sand, netting, Pukani rock and a load of Sch 80 pipe, valves, bulkheads and fittings from BRS.

DivingTheWorld

Active member

I did some investigating of the furniture in our family room where the aquarium is going. The manufacturer just writes, "Selected Hard Woods" and the finish as "Dark Rustic". Not very helpful... They have another furniture line which looks very similar and with those they say the wood is "Cherry Veneer" with a finish as "Burnished Brown".

So...I think the go to may be Cherry with a brownish finish. More investigating needed...

So Sherwin Williams found me a matching stain for Alder. So that's what I'll be using for my stand skin.

DivingTheWorld

Active member

DivingTheWorld

Active member

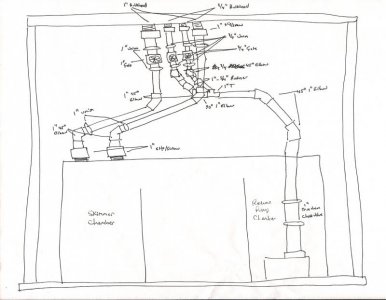

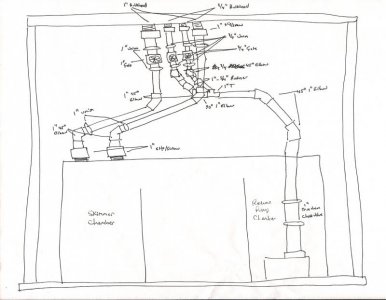

Ok, here's my plans for plumbing. I know, I know, I'm no artist! lol Anyways, let me know what you think. I would love some feedback.

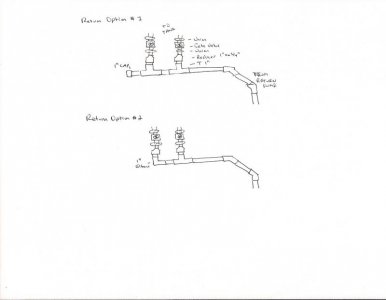

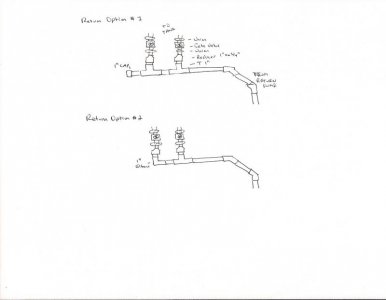

Here's a slightly better drawing of my return manifold. I'd like the ability to add reactors, etc. down the road. I'm going with a larger return pump and can crank it up in the future if I want.

So... I was thinking I could just have a connection capped off at the end just past the verticle returns.

Or... I just do a 90 degree elbow at the end of the manifold and cut into the plumbing somewhere before the manifold when I'm ready to run reactors.

Thoughts?

Here's a slightly better drawing of my return manifold. I'd like the ability to add reactors, etc. down the road. I'm going with a larger return pump and can crank it up in the future if I want.

So... I was thinking I could just have a connection capped off at the end just past the verticle returns.

Or... I just do a 90 degree elbow at the end of the manifold and cut into the plumbing somewhere before the manifold when I'm ready to run reactors.

Thoughts?

greengeco82

Reefer

Cap the end, or better yet, just make the manifold. You say you want a SPS tank, so I assume you might be running GFO, carbon, a chiller, and/or reactor. Its easier to do professional looking plumbing when the stand is empty vs adding on with a full sump and all of the electrical in the way. Just my two cents.

I also like the return. I just did mine the same as your diagram. Just watch out for the valves. I noticed the inside diameter of my 1" valves is 3/4". In other words the valves can restrict flow. I think since you are splitting the flow to 2 different returns then you wont have to worry about the smaller inside diameter.

I also like the return. I just did mine the same as your diagram. Just watch out for the valves. I noticed the inside diameter of my 1" valves is 3/4". In other words the valves can restrict flow. I think since you are splitting the flow to 2 different returns then you wont have to worry about the smaller inside diameter.

DivingTheWorld

Active member

or better yet, just make the manifold.

Do you mean make the whole manifold to the reactors? One other option is instead of a cap on the end, I can add a gate valve to a screw cap. I can just close the gate. Then when I'm ready to add a reactor(s), I can just unscrew the cap, hook it up, and turn on the valve. Better idea, worse?

Just watch out for the valves. I noticed the inside diameter of my 1" valves is 3/4". In other words the valves can restrict flow.

This has me a little concerned on the main drain. I'm running a Herbie style, so need a good amount of main drain flow, around 800gph (I may reduce that flow).

greengeco82

Reefer

Seems like we are doing similar builds, as far as plumbing goes. I also am concerned about my drain valve having a smaller inside diameter. I bought my valves as Low's. I believe there are better valves out there. I couldnt find them at OSH or Low's, but you should be able to order them from BRS. I was advised to buy a gate valve instead of a ball valve to have more precise control of the drain flow. Me, Im just going with the ball valve since I have the materials already. Im going to cross my fingers, and hope I dont have to replace it later with a gate valve.

As for the manifold. Here is how I am doing mine. It starts with a Waveline pump which comes with a barbed fitting. Goes the a vinyl hose, to another barbed fitting, to a reduced diameter fitting (name?), to a series of threaded T fittings, then to my returns. I wont be using all of the valves from the T fitting, they are just there for future expansions. Not saying this is the right way, just my best answer to how I am doing mine. Here is a pic of mine for reference.

As for the manifold. Here is how I am doing mine. It starts with a Waveline pump which comes with a barbed fitting. Goes the a vinyl hose, to another barbed fitting, to a reduced diameter fitting (name?), to a series of threaded T fittings, then to my returns. I wont be using all of the valves from the T fitting, they are just there for future expansions. Not saying this is the right way, just my best answer to how I am doing mine. Here is a pic of mine for reference.

greengeco82

Reefer

Those manifold valves are threaded, and there is a huge selection of barbed fitting that will screw right in at Low's.

DivingTheWorld

Active member

These are the gate valves I ordered:

http://www.bulkreefsupply.com/spears-gate-valve-slip-x-slip-2.html

I'm taking advantage of these Black Friday sales!

I'm planning to sandwich each one in between two Sch 80 Slip Unions.

http://www.bulkreefsupply.com/spears-gate-valve-slip-x-slip-2.html

I'm taking advantage of these Black Friday sales!

I'm planning to sandwich each one in between two Sch 80 Slip Unions.

Similar threads

- Replies

- 2

- Views

- 313