This thread will highlight the solutions I've come up with to some problems I've encountered while keeping saltwater tanks. Quick background on me, I'm nearly done with my electrical engineering degree at UA and have two 3D printers at home.

I'm posting this in the local forum for a couple reasons. The first is for feedback on whether or not anyone wants me to make them a similar 3D print as I am thinking about trying to sell them at frag swaps. I'm not really trying to make a lot of money from these, I think they'll generally help people out and eliminate some frustrating problems. The other reason is for input on improved design, if the project is not super practical for most tanks, or new problems that I might not have in my tanks that I could try and figure out. It's fun working on these and assembling the finished product

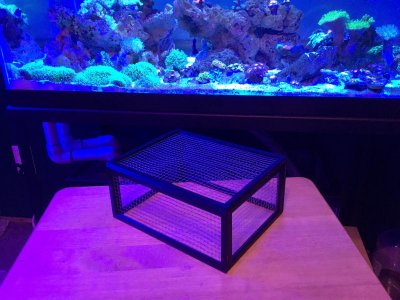

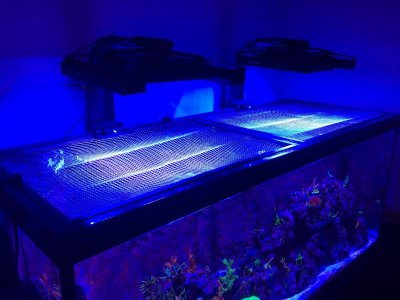

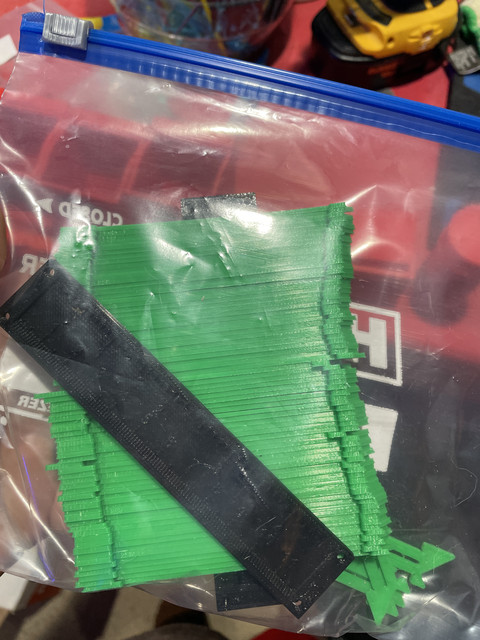

It's also important to note that I've tested the materials used in these projects and I'm confident everything is reef safe. I use black ABS plastic, gorilla glue gel for bonding, and standard mesh netting. The finished design is generally very strong and I've found the plastic is more likely to break then the super glue bond itself. I've made a couple mistakes with prototypes and getting two pieces of plastic apart once the glue is settled is near impossible without destroying both pieces entirely. When going over each project I'll also talk about how it's put together and the best practices I've found so if anyone else has access to a 3D printer they can build it themselves.

I'm posting this in the local forum for a couple reasons. The first is for feedback on whether or not anyone wants me to make them a similar 3D print as I am thinking about trying to sell them at frag swaps. I'm not really trying to make a lot of money from these, I think they'll generally help people out and eliminate some frustrating problems. The other reason is for input on improved design, if the project is not super practical for most tanks, or new problems that I might not have in my tanks that I could try and figure out. It's fun working on these and assembling the finished product

It's also important to note that I've tested the materials used in these projects and I'm confident everything is reef safe. I use black ABS plastic, gorilla glue gel for bonding, and standard mesh netting. The finished design is generally very strong and I've found the plastic is more likely to break then the super glue bond itself. I've made a couple mistakes with prototypes and getting two pieces of plastic apart once the glue is settled is near impossible without destroying both pieces entirely. When going over each project I'll also talk about how it's put together and the best practices I've found so if anyone else has access to a 3D printer they can build it themselves.