BigDave

Premium Member

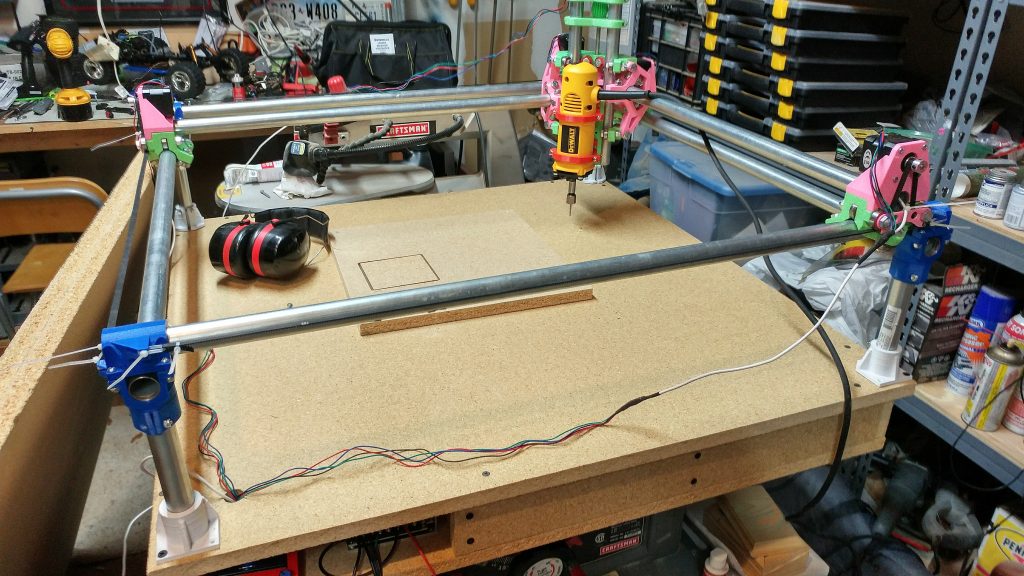

I'm now 64 hours in to printing the parts for the CNC machine with another 30 hours left to go. I've had only two hiccups in all the printing.

One was some of the parts came out a tad small. I think the tolerances are a bit tight. I bumped up the prints by 1% and they printed better the second time.

The second hiccup was I had a nut come loose on the build platform. The plate went un-level. I caught it at about 4 hours in to the 6 hour print. I replaced the nuts with some NyLock ones and took the opportunity to add some thumb wheels to the nuts so I don't have to use a wrench to adjust the level anymore.

I actually have an inductance meter to use for auto-level, just haven't bothered to design a mount for it yet. I don't like most of the mounts on thingiverse... or I should say, I really like the fan blower I have and none of the mounts will work with that.

I'll try to get some more pictures of more of the parts this evening. I've decided to shrink the initial build platform. My CNC will have a 24"x24" cut size.

One was some of the parts came out a tad small. I think the tolerances are a bit tight. I bumped up the prints by 1% and they printed better the second time.

The second hiccup was I had a nut come loose on the build platform. The plate went un-level. I caught it at about 4 hours in to the 6 hour print. I replaced the nuts with some NyLock ones and took the opportunity to add some thumb wheels to the nuts so I don't have to use a wrench to adjust the level anymore.

I actually have an inductance meter to use for auto-level, just haven't bothered to design a mount for it yet. I don't like most of the mounts on thingiverse... or I should say, I really like the fan blower I have and none of the mounts will work with that.

I'll try to get some more pictures of more of the parts this evening. I've decided to shrink the initial build platform. My CNC will have a 24"x24" cut size.