Realized I should probably post this in this section

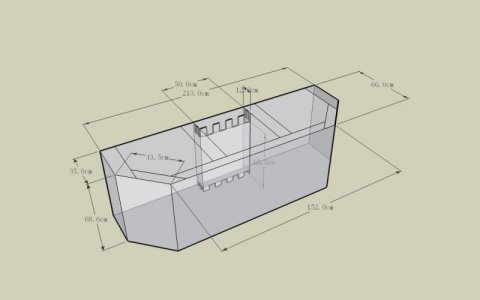

I ordered a new tank and it just came in and one of the angled vertical panels is a problem. At the top the space between the joints/panels is 1/16" while at the bottom the glass is 1/4" apart!!! I guess they cut the panel wrong or something and just made up the difference with extra silicone.

Its very noticeable and doesn't look great but that aside is it structurally sound! I am kinda in a bind as I have everything in temporary holding tanks and I won't be able to get another tank made for 2-3months. I can live with the aesthetics but what about the structural implications? The tank is 3/4" thick and the panels are angled (45degrees) so its about a 1" joint of silicone. We had our previous acrylic tank seam let go so wife is paranoid about a failing tank. I just don't know what to do..... HELP

Mike

I ordered a new tank and it just came in and one of the angled vertical panels is a problem. At the top the space between the joints/panels is 1/16" while at the bottom the glass is 1/4" apart!!! I guess they cut the panel wrong or something and just made up the difference with extra silicone.

Its very noticeable and doesn't look great but that aside is it structurally sound! I am kinda in a bind as I have everything in temporary holding tanks and I won't be able to get another tank made for 2-3months. I can live with the aesthetics but what about the structural implications? The tank is 3/4" thick and the panels are angled (45degrees) so its about a 1" joint of silicone. We had our previous acrylic tank seam let go so wife is paranoid about a failing tank. I just don't know what to do..... HELP

Mike