I am planning on setting up a 180 or 220 tank as a peninsula tank and want to plumb the tank on one end. I have thought about getting the tank set up as reef ready tank but I really don't want the black plastic over flows in the tank.

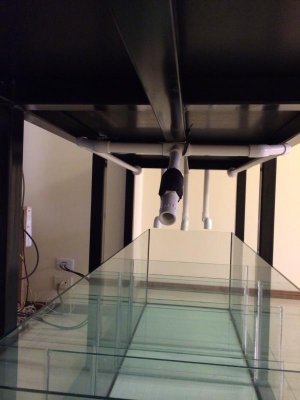

My question is has any one drilled tank on the end? and what size holes.

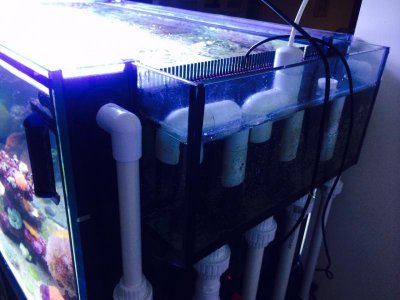

I was thinking of 2 holes for drains to the sump and one return hole which I could use lock lines in the tank for return in the tank.

The other thought would be to plumb the return to the tank out side of the tank and up and ove to the far end and then back down into the tank.

The tank will be going into the lower level of the house next to the joist support that supports the upper floor, which will help hid the support and give me the room to plug on the end. It will also give allow the tank to be viewed from 3 sides.

Any ideas would be greatly appreciated

TIA

John

My question is has any one drilled tank on the end? and what size holes.

I was thinking of 2 holes for drains to the sump and one return hole which I could use lock lines in the tank for return in the tank.

The other thought would be to plumb the return to the tank out side of the tank and up and ove to the far end and then back down into the tank.

The tank will be going into the lower level of the house next to the joist support that supports the upper floor, which will help hid the support and give me the room to plug on the end. It will also give allow the tank to be viewed from 3 sides.

Any ideas would be greatly appreciated

TIA

John