treesprite

Member

Has anyone here done this who can give info, advice, pictures/videos? Or perhaps just point me to other posts with examples?

I have another thread here recently started - trying to figure out what to do with the 120 g tank I'm working on - and I liked the idea someone gave me about making an external overflow. The tank only has one drain (not including the CL), which just won't do, and I would not mind doing this as much as I would drilling more holes.

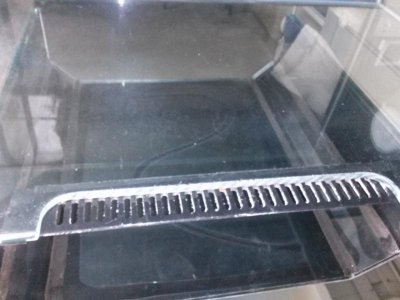

This is the tank, before I stripped off the black paint:

The slot would go between the two upper returns, but of course up higher, by the trim.

I made a short external overflow on a 65 gallon tank many years ago, but was only able to do it as a result of me breaking the upper corner of the tank and not being able to afford a new tank. I had to take out the back panel, had a shop cut off the top of it then cut off the broken end. Then I sealed it back on making a sandwich of glass pieces epoxied over the seam, except on that end into which I created an external overflow. I have no intention of taking apart this 120 gallon tank, but now that I have seen an example of slotting the back with a handheld tool, I'm getting kind of itchy. If I end up not doing it on the 120, I might try it on a smaller tank as I usually have a couple sitting around.

Thanks in advance for your responses and assistance!

I have another thread here recently started - trying to figure out what to do with the 120 g tank I'm working on - and I liked the idea someone gave me about making an external overflow. The tank only has one drain (not including the CL), which just won't do, and I would not mind doing this as much as I would drilling more holes.

This is the tank, before I stripped off the black paint:

The slot would go between the two upper returns, but of course up higher, by the trim.

I made a short external overflow on a 65 gallon tank many years ago, but was only able to do it as a result of me breaking the upper corner of the tank and not being able to afford a new tank. I had to take out the back panel, had a shop cut off the top of it then cut off the broken end. Then I sealed it back on making a sandwich of glass pieces epoxied over the seam, except on that end into which I created an external overflow. I have no intention of taking apart this 120 gallon tank, but now that I have seen an example of slotting the back with a handheld tool, I'm getting kind of itchy. If I end up not doing it on the 120, I might try it on a smaller tank as I usually have a couple sitting around.

Thanks in advance for your responses and assistance!

Last edited: