jccaclimber

Member

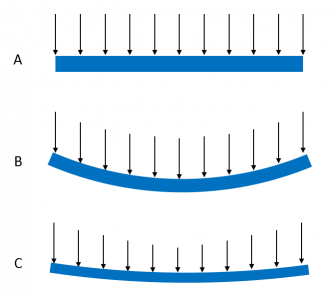

I'm looking to make a stand for a large (126"l x 34"d x 32"h) glass tank, with the goal of maximizing the open space between legs. When asking around about support I either hear "Put a vertical every 2 feet" or "It must be uniformly supported" (case A).

I believe proper design can get around putting a vertical every 2 feet, and "uniformly supported" is an awfully vague statement. I'm looking for some guidance on what is actually needed.

Let's start this with the RocketEngineer stand here:

http://reefcentral.com/forums/showthread.php?t=1169964

I'm choosing that because there are a lot of them out there, and because they happen to be really easy to make. If you ignore the beams going front to back (is this an acceptable simplification?*) it's a beam, supported at each end.

Let's assume a 75 gallon tank weighs 700 lbf. Spread it across two 2x4's with a 41" span between the legs. If you apply a uniform load to a beam, the center bends down (case B). In this case I'm coming up with ~0.030" deflection at the center of the stand*.

Doing the same for a 6' 125 gallon tank weighing 1100 lbf I come up with 0.055" deflection at the center of the 65" free span.

My first two thoughts are:

1) The tank doesn't bend this much (or does it?), so the center is actually less supported than the ends (case C, what I think actually happens).

2) A 6' 2x6 isn't straight to within 0.055" to begin with. Additionally if the legs aren't equal length the frame will twist to meet the floor so once more, the tank isn't "perfectly" uniformly supported.

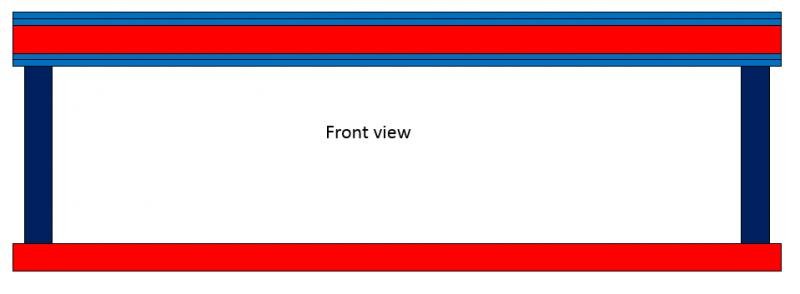

As additional evidence consider the stand for my 8' 300 gallon. It has legs at each corner (86" open span). The top is 1.5" of plywood on each side of 4 vertical 2x4's (total height 1.5+3.5+1.5=6.5") with a sheet of styrofoam between the tank and stand.

Uniformly loaded it would deflect 0.045" at mid span. I haven't tried to measure deflection since the first fill years ago, although it was about the expected amount then. I know that it deflects, but I also know the stand carries a higher share of weight at the ends than the center. I made the stand with a very slight rise in the center, so when the tank is empty you can slip a sheet of paper freely between the tank and stand at the ends. With the tank full this reverses, the ends are loaded (and the foam compressed slightly), but I can slip a business card between the foam and stand at the center with only slight drag.

My question: What sort of support should I actually be going for here?

*1) I also know that many aquariums are edge supported. In my case they glass ones don't have a frame and the 8' tank is acrylic, so they are all supported along the entire surface rather than just at the edges making my 2d simplification at least slightly more appropriate.

*2) I am using 1.5e6 psi for Young's modulus of wood.

I believe proper design can get around putting a vertical every 2 feet, and "uniformly supported" is an awfully vague statement. I'm looking for some guidance on what is actually needed.

Let's start this with the RocketEngineer stand here:

http://reefcentral.com/forums/showthread.php?t=1169964

I'm choosing that because there are a lot of them out there, and because they happen to be really easy to make. If you ignore the beams going front to back (is this an acceptable simplification?*) it's a beam, supported at each end.

Let's assume a 75 gallon tank weighs 700 lbf. Spread it across two 2x4's with a 41" span between the legs. If you apply a uniform load to a beam, the center bends down (case B). In this case I'm coming up with ~0.030" deflection at the center of the stand*.

Doing the same for a 6' 125 gallon tank weighing 1100 lbf I come up with 0.055" deflection at the center of the 65" free span.

My first two thoughts are:

1) The tank doesn't bend this much (or does it?), so the center is actually less supported than the ends (case C, what I think actually happens).

2) A 6' 2x6 isn't straight to within 0.055" to begin with. Additionally if the legs aren't equal length the frame will twist to meet the floor so once more, the tank isn't "perfectly" uniformly supported.

As additional evidence consider the stand for my 8' 300 gallon. It has legs at each corner (86" open span). The top is 1.5" of plywood on each side of 4 vertical 2x4's (total height 1.5+3.5+1.5=6.5") with a sheet of styrofoam between the tank and stand.

Uniformly loaded it would deflect 0.045" at mid span. I haven't tried to measure deflection since the first fill years ago, although it was about the expected amount then. I know that it deflects, but I also know the stand carries a higher share of weight at the ends than the center. I made the stand with a very slight rise in the center, so when the tank is empty you can slip a sheet of paper freely between the tank and stand at the ends. With the tank full this reverses, the ends are loaded (and the foam compressed slightly), but I can slip a business card between the foam and stand at the center with only slight drag.

My question: What sort of support should I actually be going for here?

*1) I also know that many aquariums are edge supported. In my case they glass ones don't have a frame and the 8' tank is acrylic, so they are all supported along the entire surface rather than just at the edges making my 2d simplification at least slightly more appropriate.

*2) I am using 1.5e6 psi for Young's modulus of wood.