BigJohnny

Active member

Hey Reefers,

I've been a sumpless reefer for 2 years now (not my choice but due to gallon restrictions imposed by landlord). Just bought a house and will be starting a new 90g DT/40g Sump build.

I have never built a sump before but have a general idea of what id like, I am just not sure how I should place the baffles to minimize issues/maximize performance.

I will be converting a 90g rr to Herbie with HOB return (or drilled if i feel brave and the back isnt tempered). The 3/4" will be full siphon and the 1" drain will be emergency (haven't decided on 100% dry or trickle yet). Then there will be a 3/4" return.

I plan on building my stand 40" tall because I am 6'4"with long arms, hate crouching all the way down to view my tank, and have determined that it is the ideal size for viewing while still maintaining ease of maintenance. I also like the idea of having all that vertical room under the stand.

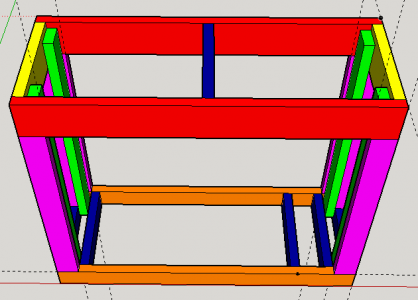

Here is a sketchup of my stand. Basic 2x4 construction (based on Rocket Engineer's plans) except i am using 2x6" for the top frame just in case. The stand is tall enough that it doesn't mess with my under stand space so why not. The additional supports on the bottom are to support the 40b sump completely around the trim. I will be skinning it with 1/2" or 3/4" ply and the sump will sit on ply as well.

Let's start with Stand:

What dimensions should i actually build the top and bottom frames? Deep Blue 90g RR Corner overflow dimensions are supposedly 48"x18"x24", but i know that is not exact and it is better to have a little underhang than any overhang. Currently its 49x19 in sketchup

Return pump/Plumbing:

-What size return pump would I need? Im thinking the sicce syncra 4.0 (about 950gph) but i dont know if that is a good match for the setup/drain and return size/stand height/tank height.

-What type of plumping?

==>Schedule 40 or Schedule 80?

==>Besides gate valve to tune full siphon, what additional check valves/unions should i get and where should i place them? I want safest set up possible.

==>I am told the emergency going straight down is best (and the full siphon too i guess), but due to the corner overflow and sump location i will need either some 45 degree or flexible tubing for one if not both drains, which is better?

==>flexible tubing or hard plumbed return?

Sump

I think i want 3 sections from left to right, drain1 filter sock)/skimmer section (vertex omega 150), refugium, return section.

i believe a forced under baffle than over another baffle from the drain/skimmer to the refugium is a good bubble trap(so im told).

My biggest concern really is, how do i control which section evaporates/to use the ato on, and how tall do i make the baffles to keep everything at the proper level for equipment function. I also dont know how much i have to adjust that based on return pump shutting off and the sump being able to accept the additional water volume. I was planning on only using about half the water volume of the sump which im told leaves plenty of spare room. The refugium is my lowest priority so i would rather improve all other aspects and shrink the refugium if necessary.

I have a tunze osmolator which is an epic ATO in case that matters. ATO container will be outside of the stand.

I cannot tell you how much i would appreciate some of you experienced reefers walking me through this. Especially if someone has a similar set up or even just a 40b sump, pictures and assistance would be greatly appreciated. I'm a little nervous about the whole thing so you guys would really be doing me a solid.

Thanks so much!

-Big J

I've been a sumpless reefer for 2 years now (not my choice but due to gallon restrictions imposed by landlord). Just bought a house and will be starting a new 90g DT/40g Sump build.

I have never built a sump before but have a general idea of what id like, I am just not sure how I should place the baffles to minimize issues/maximize performance.

I will be converting a 90g rr to Herbie with HOB return (or drilled if i feel brave and the back isnt tempered). The 3/4" will be full siphon and the 1" drain will be emergency (haven't decided on 100% dry or trickle yet). Then there will be a 3/4" return.

I plan on building my stand 40" tall because I am 6'4"with long arms, hate crouching all the way down to view my tank, and have determined that it is the ideal size for viewing while still maintaining ease of maintenance. I also like the idea of having all that vertical room under the stand.

Here is a sketchup of my stand. Basic 2x4 construction (based on Rocket Engineer's plans) except i am using 2x6" for the top frame just in case. The stand is tall enough that it doesn't mess with my under stand space so why not. The additional supports on the bottom are to support the 40b sump completely around the trim. I will be skinning it with 1/2" or 3/4" ply and the sump will sit on ply as well.

Let's start with Stand:

What dimensions should i actually build the top and bottom frames? Deep Blue 90g RR Corner overflow dimensions are supposedly 48"x18"x24", but i know that is not exact and it is better to have a little underhang than any overhang. Currently its 49x19 in sketchup

Return pump/Plumbing:

-What size return pump would I need? Im thinking the sicce syncra 4.0 (about 950gph) but i dont know if that is a good match for the setup/drain and return size/stand height/tank height.

-What type of plumping?

==>Schedule 40 or Schedule 80?

==>Besides gate valve to tune full siphon, what additional check valves/unions should i get and where should i place them? I want safest set up possible.

==>I am told the emergency going straight down is best (and the full siphon too i guess), but due to the corner overflow and sump location i will need either some 45 degree or flexible tubing for one if not both drains, which is better?

==>flexible tubing or hard plumbed return?

Sump

I think i want 3 sections from left to right, drain1 filter sock)/skimmer section (vertex omega 150), refugium, return section.

i believe a forced under baffle than over another baffle from the drain/skimmer to the refugium is a good bubble trap(so im told).

My biggest concern really is, how do i control which section evaporates/to use the ato on, and how tall do i make the baffles to keep everything at the proper level for equipment function. I also dont know how much i have to adjust that based on return pump shutting off and the sump being able to accept the additional water volume. I was planning on only using about half the water volume of the sump which im told leaves plenty of spare room. The refugium is my lowest priority so i would rather improve all other aspects and shrink the refugium if necessary.

I have a tunze osmolator which is an epic ATO in case that matters. ATO container will be outside of the stand.

I cannot tell you how much i would appreciate some of you experienced reefers walking me through this. Especially if someone has a similar set up or even just a 40b sump, pictures and assistance would be greatly appreciated. I'm a little nervous about the whole thing so you guys would really be doing me a solid.

Thanks so much!

-Big J