Hi,

I've been lurking for a while and decided to share information about my project build.

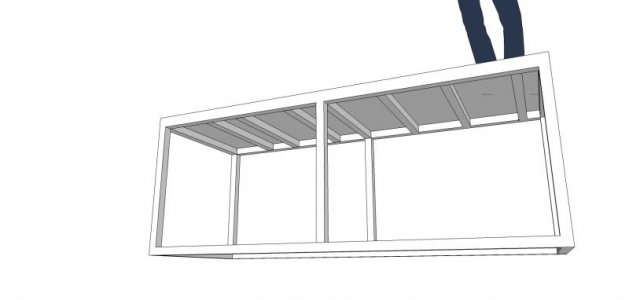

I'm installing a 200 gallon in-wall tank as a room divider in a master suite. As I go along I will share my thrills and chills. I also want to share some of my DIY stuff in hopes of encouraging others to do the same.

This is my second reef tank, and it's been about 12 years since the last one. The last one was a 135 gallon show tank.

The new tank (to me) is a used custom all-glass tank sourced via Craigslist. It is 72" long, 25" wide and 30" deep with an approximate water depth of 24". It's made of 1/2" non-tempered glass with a 1/2" plywood bottom backer.

As I'm on a budget I try to renovate and innovate wherever possible, while still installing a nice system.

Here is some HD video I shot when I drilled the return holes in the tank. The tank does not have an overflow so I am building one. I've chosen to locate the holes on the side of the tank because - A) the end glass is less complicated to replace then the bottom in the event it breaks, B) In the event that my overflow fails I will not lose all of my water., C) it conserves tank space for animals.

http://www.youtube.com/watch?v=r9x9vV2cXRY

I've been lurking for a while and decided to share information about my project build.

I'm installing a 200 gallon in-wall tank as a room divider in a master suite. As I go along I will share my thrills and chills. I also want to share some of my DIY stuff in hopes of encouraging others to do the same.

This is my second reef tank, and it's been about 12 years since the last one. The last one was a 135 gallon show tank.

The new tank (to me) is a used custom all-glass tank sourced via Craigslist. It is 72" long, 25" wide and 30" deep with an approximate water depth of 24". It's made of 1/2" non-tempered glass with a 1/2" plywood bottom backer.

As I'm on a budget I try to renovate and innovate wherever possible, while still installing a nice system.

Here is some HD video I shot when I drilled the return holes in the tank. The tank does not have an overflow so I am building one. I've chosen to locate the holes on the side of the tank because - A) the end glass is less complicated to replace then the bottom in the event it breaks, B) In the event that my overflow fails I will not lose all of my water., C) it conserves tank space for animals.

http://www.youtube.com/watch?v=r9x9vV2cXRY