Air lifts can be as simple as a pressure rated air pump with diffusers that lift water from the bottom to the surface for oxygenation, or a 2" PVC pipe with an elbow on the top and an airline running to the bottom. As air rises, it draws in water and brings it to the surface. It's a much more efficient method of gas-exchange than horizontal water flow from a water pump, but they both have their merits.

Air blowers are cost effective to run, but they don't push air deeper than about a metre. A piston pump would be better suited for the pressure requirement, but they are noisy. A compressor will also work, but again not very relaxing to hear when you are enjoying the view.

This windmill will move water from the ocean to your display tank.

http://www.airliftech.com/ You could have it on a constant feed and you will have no need for nutrient export methods such as protein skimming, carbon, or a refugium.

Here is a windmill that will run an airlift for circulation. There are many on the market, this one just came up on the first page and it has a diagram of an airlift pipe like the one I mentioned.

http://www.koenderswindmills.com/Koenders_Windmills_AirDr.html

You mentioned mangroves before; they make a really nice display as a separate water garden, but they are not very efficient water cleaners as they grow very slowly. If you raise and lower the water level daily, the mangroves will grow the "legs" they are famous for. Seagrass would be a more efficient method.

If you have a high bacteria, parasite, & free floating algae (phytoplankton) count in your local water, then you may have to first store the water and hyperchlorinate (bleach) it. You can dechlorinate it with sodium thiosulphate or with an airlift (off-gassing). A pool chlorine test kit will give you accurate readings to assure you are adding enough to sterilize the water and removing the chlorine before it is added to the tank.

Be careful with the shade cloth design. There is no problem with mounting it high above the tank, but be careful it doesn't become a giant kite and fly away into the desert

You may want to look into a partial greenhouse structure that has ridge vents at the top to allow heat to escape. These are powered by a piston that is activated by an oil that is heated up by the sun when it gets to hot (zero operating cost). The metal structure of a greenhouse with no poly-plastic side walls will hold your shade cloth in place on the windiest days.

Good to hear about the concrete. I guess it is a common material in your area.

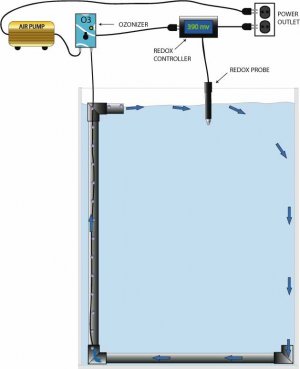

As far as filtration goes, I would use only water changes (providing the incoming water is good) and ozone. A 5-10 gram per hour unit will kill pathogens (bacteria & parasites) as well as unwanted algae blooms. You can set it up on a redox controller so it only comes on when you need it and it shuts off before you get harmful residual ozone. You can use ozone with the airlifts. Ozonation of the seawater as it enters your system is another good idea. They don't draw much electricity and run very efficiently on dry air which you should have lots of

If you build a wall or structure to cast a shadow on the viewing panels, they will grow less algae (less cleaning), it will minimize glare, and the display tank will look more dramatic.

Do you have some kind of protection against sand damaging the tank when the wind blows? My wife & I went out on ATV's and camels in Egypt last year and she ruined her eye glasses in a couple of days. Lesson learned, don't mess with natures sandblaster

Here is a drawing of how you could use a simple air & ozone system for disease control, water quality management, and water flow dynamics.