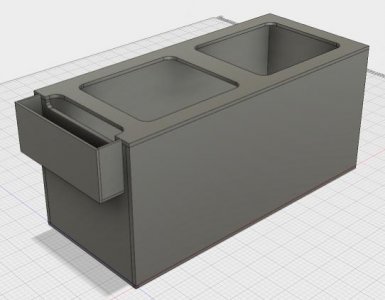

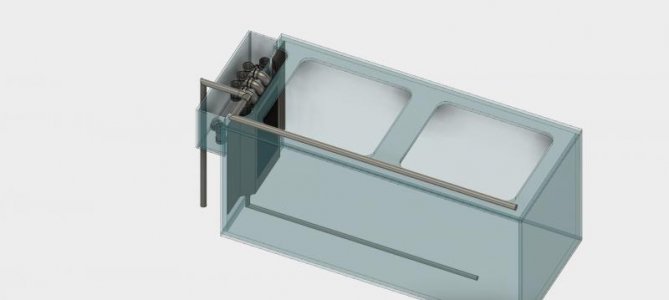

I am almost ready to start cutting acrylic for peninsula tank, need your opinion on a few details. The tank is about 68"x30"x30", 1" thick sides, 3/4" top and bottom, 1/2" overflow box. The top braces are 4" wide, and the big central one is 6" wide.

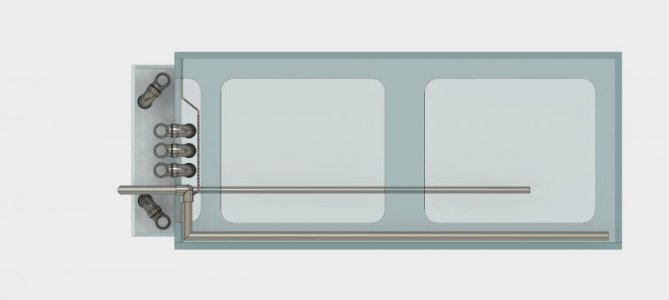

One thing I am concerned about is the overflow area. The cross-brace there is 7" wide, but has 3" cutout almost along the whole length making it effectively 4" wide, and not attached to the back.

Another question (a few actually) is about drilling the eurobrace for CL returns. Where is a safe/good place to drill and are there any special considerations about it? I plan to drill at least 3, one inch holes on each side. Apologies if this seems like a basic question, it was certainly done many times, but I could not find any specific info about it.

So:

1. How is the plan in general?

2. Do you see any problems with the overflow area?

3. Are (all, or some of) the braces wide enough.

4. Where would you drill the CL holes in the brace? How large can they be/are the braces wide enough for them? Do I need to do anything special there, e.g., make brace wider, reinforce, etc.. (btw, I do plan to route them to have a clean hole)?

Thanks a lot,

Andrey