You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acrylic fabrication questions? I can help!

- Thread starter JohnL

- Start date

weld on

weld on

Could someone tell me the difference between Weld-On 4, Weld-on 16, and Weld-on 40? I have been reading a few things on the web about building acrylic tanks and some of them say to use the 4 and some of them say to use the 40 and one of them said to use the 4 and then use the 16 to fill any gaps that were left after using the 4. I'm assuming that the higher the number the thicker the solvent? Is one better that another?

After some practice I was considering trying to build my own tank (96x 48 wide x 30 tall). I've never made my own tank before, but I'm pretty handy. I'm a technology teacher, so I have access to a wide range of tools/machines. Any suggestions or should I not even attempt to do this?

Thanks for any info

Jason

weld on

Could someone tell me the difference between Weld-On 4, Weld-on 16, and Weld-on 40? I have been reading a few things on the web about building acrylic tanks and some of them say to use the 4 and some of them say to use the 40 and one of them said to use the 4 and then use the 16 to fill any gaps that were left after using the 4. I'm assuming that the higher the number the thicker the solvent? Is one better that another?

After some practice I was considering trying to build my own tank (96x 48 wide x 30 tall). I've never made my own tank before, but I'm pretty handy. I'm a technology teacher, so I have access to a wide range of tools/machines. Any suggestions or should I not even attempt to do this?

Thanks for any info

Jason

hillscp

Soylent Green is People!!

This was posted in a separate thread but got no response. Maybe I'll do better here

I originally planned to build an acrylic sump from scratch but I got a killer deal on a Sea Clear 55 acrylic aquarium for 50 bucks. Now I'm backtracking on the design.

The plan right now is to add dividers and a fuge to this tank to go under my 125 long AGA build. I need some advice on how to add the dividers to an existing tank. I think the difficulty is that my original plan was to add the dividers during assembly by cementing them to the back before the front was cemented on. Having the tank assembled might make this a little trickier because there won't be any room for pins and such during the assembly. Also, the tolerances will be more difficult since the ends and dividers won't be cut at the same time.

The tank dimensions are 20" High X 13" Deep X 48 long. It will fit under the stand which has 31" between the floor and the top so that gives me 11" to spare.

There is 5" of material on the ends to plumb the returns with bulkheads. Also, is the center brace needed since I am going to add dividers? I am thinking that the dividers should keep the tank from bowing out.<br />

<img src="http://chicowoodnut.home.comcast.net/~chicowoodnut/aquarium/images/Sump/IMG_0800.JPG" border="0" alt="" />

<img src="http://chicowoodnut.home.comcast.net/~chicowoodnut/aquarium/images/Sump/IMG_0801.JPG" border="0" alt="" />

Here is a sketchup export of the plans for the guts. Can I make the baffles and fuge section taller? This tank is taller than the one I was designing to build from scratch. Would it be better to cut the top off of it or am I making it too hard?

<img src="http://chicowoodnut.home.comcast.net/~chicowoodnut/aquarium/images/Sump/55TankMod2Baffles.jpg" border="0" alt="" />

I originally planned to build an acrylic sump from scratch but I got a killer deal on a Sea Clear 55 acrylic aquarium for 50 bucks. Now I'm backtracking on the design.

The plan right now is to add dividers and a fuge to this tank to go under my 125 long AGA build. I need some advice on how to add the dividers to an existing tank. I think the difficulty is that my original plan was to add the dividers during assembly by cementing them to the back before the front was cemented on. Having the tank assembled might make this a little trickier because there won't be any room for pins and such during the assembly. Also, the tolerances will be more difficult since the ends and dividers won't be cut at the same time.

The tank dimensions are 20" High X 13" Deep X 48 long. It will fit under the stand which has 31" between the floor and the top so that gives me 11" to spare.

There is 5" of material on the ends to plumb the returns with bulkheads. Also, is the center brace needed since I am going to add dividers? I am thinking that the dividers should keep the tank from bowing out.<br />

<img src="http://chicowoodnut.home.comcast.net/~chicowoodnut/aquarium/images/Sump/IMG_0800.JPG" border="0" alt="" />

<img src="http://chicowoodnut.home.comcast.net/~chicowoodnut/aquarium/images/Sump/IMG_0801.JPG" border="0" alt="" />

Here is a sketchup export of the plans for the guts. Can I make the baffles and fuge section taller? This tank is taller than the one I was designing to build from scratch. Would it be better to cut the top off of it or am I making it too hard?

<img src="http://chicowoodnut.home.comcast.net/~chicowoodnut/aquarium/images/Sump/55TankMod2Baffles.jpg" border="0" alt="" />

troylee

In Memoriam

Weld on 4 is a water thin solvent and the strongest of all the glue/solvents you mention....it requires a perfectly smooth routed edge to work best....Could someone tell me the difference between Weld-On 4, Weld-on 16, and Weld-on 40? I have been reading a few things on the web about building acrylic tanks and some of them say to use the 4 and some of them say to use the 40 and one of them said to use the 4 and then use the 16 to fill any gaps that were left after using the 4. I'm assuming that the higher the number the thicker the solvent? Is one better that another?

After some practice I was considering trying to build my own tank (96x 48 wide x 30 tall). I've never made my own tank before, but I'm pretty handy. I'm a technology teacher, so I have access to a wide range of tools/machines. Any suggestions or should I not even attempt to do this?

Thanks for any info

Jason

Weldon 16 is garbage stay away from it!!!!!!!

Weldon 40 is a 2 part acrylic monomer and hardner. Althou ips. Claims it is stronger I have done test to shoe this is false....althou it is a very good glue and can be used by itself it is defenitly worth using but a pain int butt....do some searches here on rc. You will find all the answers you are looking for..good luck..

IMO you're making it too hard, you can make the baffles whatever height you choose provided it serves your purposes. Just add them and it's done.This was posted in a separate thread but got no response. Maybe I'll do better here

I originally planned to build an acrylic sump from scratch but I got a killer deal on a Sea Clear 55 acrylic aquarium for 50 bucks. Now I'm backtracking on the design.

The plan right now is to add dividers and a fuge to this tank to go under my 125 long AGA build. I need some advice on how to add the dividers to an existing tank. I think the difficulty is that my original plan was to add the dividers during assembly by cementing them to the back before the front was cemented on. Having the tank assembled might make this a little trickier because there won't be any room for pins and such during the assembly. Also, the tolerances will be more difficult since the ends and dividers won't be cut at the same time.

The tank dimensions are 20" High X 13" Deep X 48 long. It will fit under the stand which has 31" between the floor and the top so that gives me 11" to spare.

There is 5" of material on the ends to plumb the returns with bulkheads. Also, is the center brace needed since I am going to add dividers? I am thinking that the dividers should keep the tank from bowing out.

Here is a sketchup export of the plans for the guts. Can I make the baffles and fuge section taller? This tank is taller than the one I was designing to build from scratch. Would it be better to cut the top off of it or am I making it too hard?

The tank needs the centerbrace. This tank is underbuilt with the centerbrace so to remove it would not be wise IMO, even with the addition of baffles.

For the baffles cut them just small enough so that you can place it. Use wires where you can and don't worry about it. If necessary, you can add gussets along any seems that don't appear strong enough. And even if a baffle leaks - so what?

It's a sump that you got a good deal on, it doesn't have to be pretty or perfect, just functional

James

Dattack,

I assume you are talking about the divided flat panels about an inch thick? I asked a CPR rep years ago how the heck they welded 2 seams where you couldnt get your hand or the bottle into. He grinned and said "A really long needle". Makes perfect sense. Possibly mcmaster has some really fine gauge tubing.

Seasoned reefer,

I made a jig for my router to get it up in the air just for edge routing cuttoffs. This could be used for cutting tanks shorter and then prepping the edge for gluing on a new top. Using James' 90 degree acrylic router jig as an example, I made a nice one from MDF.

Then I had a situation where I needed to route not just the edges to the same height, but some middle sections too. I made a second jig that holds the router in the air vertically. It had to be beefy to keep from walking or waving to get a good cut. You do get a slightly funky edge with the end of the bit, but a cabinet scraper cleans it right up for gluing. Its a monster to use and store, but was the only thing that would give me the correct tolerances, (since I dont work in a machine shop, LOL)

OK, who wants to be the first to send their tank through a wood planer? :hammer:

I assume you are talking about the divided flat panels about an inch thick? I asked a CPR rep years ago how the heck they welded 2 seams where you couldnt get your hand or the bottle into. He grinned and said "A really long needle". Makes perfect sense. Possibly mcmaster has some really fine gauge tubing.

Seasoned reefer,

I made a jig for my router to get it up in the air just for edge routing cuttoffs. This could be used for cutting tanks shorter and then prepping the edge for gluing on a new top. Using James' 90 degree acrylic router jig as an example, I made a nice one from MDF.

Then I had a situation where I needed to route not just the edges to the same height, but some middle sections too. I made a second jig that holds the router in the air vertically. It had to be beefy to keep from walking or waving to get a good cut. You do get a slightly funky edge with the end of the bit, but a cabinet scraper cleans it right up for gluing. Its a monster to use and store, but was the only thing that would give me the correct tolerances, (since I dont work in a machine shop, LOL)

OK, who wants to be the first to send their tank through a wood planer? :hammer:

While it's possible he used long surgical tube, he was more than likely playin' with ya ChrisDattack,

I assume you are talking about the divided flat panels about an inch thick? I asked a CPR rep years ago how the heck they welded 2 seams where you couldnt get your hand or the bottle into. He grinned and said "A really long needle". Makes perfect sense. Possibly mcmaster has some really fine gauge tubing.

If you're building many of these things, it goes quickly and you don't have to let the solvent sit more than a few minutes.

Hope this makes sense

James

I can see that working James

The CPR guy was talking about a nano tank with the built in filtration behind it. I'm sure it could be done this way as well. I guess it just takes practice to not get a sloppy joint or solvent pooling at the bottom. Plus their material is only about 1/16" You could just show it the bottle of solvent and it'd be glued

The CPR guy was talking about a nano tank with the built in filtration behind it. I'm sure it could be done this way as well. I guess it just takes practice to not get a sloppy joint or solvent pooling at the bottom. Plus their material is only about 1/16" You could just show it the bottle of solvent and it'd be glued

dragonetti

New member

I have a question about 1/2" acylite ff (extruded). I picked up some for cheap and have heard it's a no-no to build a tank with it (after the fact). Will it be okay to build 36" x 18" x 16" (40 breader) with it? What about a 48" x 18" x 16"? Both braced.

Last edited:

LOL, that's the way I see extruded, glues so easily, could damn near glue the stuff with just vaporsPlus their material is only about 1/16" You could just show it the bottle of solvent and it'd be glued

Yep, it'll be fineI have a question about 1/2" acylite ff (extruded). I picked up some for cheap and have heard it's a no-no to build a tank with it (after the fact). Will it be okay to build 36" x 18" x 16" (40 breader) with it? What about a 48" x 18" x 16"? Both braced.

Other than not being as able to handle stresses as well as a good cell cast - there is little to no difference between the two. Virtually every other physical & optical quality is the same or *really* close.

HTH,

James

framschwaa

New member

Acrylics,

This has probably been asked, but this thread is like a 800 pound gorilla, so I'm going to ask again if that's ok?

I work in a machine shop(in Cleveland btw) and we machine all types of thermoplastics... We do not however do much bonding of acrylics, and definitely not for aquarium applications. Would an endmilled edge done on a CNC Router/VMC give an edge finish(if done correctly of course) that would lend it self to bonding for an aquarium? Could you recommend a type of endmill that would give an appropriate finish if possible? We deal with Onsrud for plastic cutting mills if that helps.

Second question while I'm at it: Looking into making a rimless tank say 50 x 24 x 16....would 1" thick Polycast be thick enough for this?(without bracing of course).

TIA.

This has probably been asked, but this thread is like a 800 pound gorilla, so I'm going to ask again if that's ok?

I work in a machine shop(in Cleveland btw) and we machine all types of thermoplastics... We do not however do much bonding of acrylics, and definitely not for aquarium applications. Would an endmilled edge done on a CNC Router/VMC give an edge finish(if done correctly of course) that would lend it self to bonding for an aquarium? Could you recommend a type of endmill that would give an appropriate finish if possible? We deal with Onsrud for plastic cutting mills if that helps.

Second question while I'm at it: Looking into making a rimless tank say 50 x 24 x 16....would 1" thick Polycast be thick enough for this?(without bracing of course).

TIA.

framschwaa,

I like router bits for edge prep, much more cutting speed but an end mill can work. Highest cutting speed possible so 20,000 rpm or better. IMO you also want to use fat cutters; 1" diameter or better, small cutters tend to flex too much with thick acrylic and high feed rates. If you slow the feed rate down too much, the material will melt from the friction alone. If you speed it up too much, the edges will pit so do a little experimenting with different cutters and feed rates and see what works best for you.

FWIW, I use 1.5" dia carbide tipped 2 flute cutters at 21,000 rpm and feed rates of ~200"/minute on 1" but see what works best for you. It's kinduva "feel" thing at this point. Get close to the above and adjust as necessary

1" Polycast would be good, it'll bow a little (and I mean just a little) but will do nicely.

HTH,

James

I like router bits for edge prep, much more cutting speed but an end mill can work. Highest cutting speed possible so 20,000 rpm or better. IMO you also want to use fat cutters; 1" diameter or better, small cutters tend to flex too much with thick acrylic and high feed rates. If you slow the feed rate down too much, the material will melt from the friction alone. If you speed it up too much, the edges will pit so do a little experimenting with different cutters and feed rates and see what works best for you.

FWIW, I use 1.5" dia carbide tipped 2 flute cutters at 21,000 rpm and feed rates of ~200"/minute on 1" but see what works best for you. It's kinduva "feel" thing at this point. Get close to the above and adjust as necessary

1" Polycast would be good, it'll bow a little (and I mean just a little) but will do nicely.

HTH,

James

framschwaa

New member

framschwaa,

...

1" Polycast would be good, it'll bow a little (and I mean just a little) but will do nicely.

HTH,

James

I mentioned we machined thermoplastics, but our specialty is in polyesters and the like. It's amazing though the speeds at which can run this stuff at. I'll definitely keep that in mind. I know our large bed routers will go well upwards of 20k, but I'm not sure about spinning a 1-1/2 router bit that high. I'm thinking I'd get some looks from the guys......seems safer for some reason run in a router table as you seem to do. Might just have to find out anyways :rollface:

Back to the Polycast though. Is it that much "nicer" than Plexiglas G? I have a quote here with a $200 price difference on 1" x 4' x 8' from two of our vendors--one carries the Polycast, the other G.

once again, thanks for your time.

Give it a shot. I use a router table but still spin 1 1/2" cutters at 21,000 all day long so perfectly safe, just not many folks are exactly comfy with it.I mentioned we machined thermoplastics, but our specialty is in polyesters and the like. It's amazing though the speeds at which can run this stuff at. I'll definitely keep that in mind. I know our large bed routers will go well upwards of 20k, but I'm not sure about spinning a 1-1/2 router bit that high. I'm thinking I'd get some looks from the guys......seems safer for some reason run in a router table as you seem to do. Might just have to find out anyways :rollface:

Polyesters like PET and PETG won't chip or pit as bad as acrylic, acrylic is a harder material so these things become something to think about.

Hmm, *I* won't use anything for tanks other than Polycast, but then my price difference isn't nearly that high - maybe a buck or two per sq ft difference. You can use Plex G, many companies will and do and I don't have a problem with that - it's good material. Just that for me, I'll happily pay the minor difference for a better material. If the difference was $6/sq ft as yours is, I might think differently.Back to the Polycast though. Is it that much "nicer" than Plexiglas G? I have a quote here with a $200 price difference on 1" x 4' x 8' from two of our vendors--one carries the Polycast, the other G.

I've worked with Polycast for decades now and we have relationship built up. Couple that with the standard sheet sizes that Polycast makes vs Plex G, kind of an easy choice for me. Polycast carries as standards 4x8, 5x8, 6x8, & 6x10' while and will make custome colors (spendy but they'll do it) Plex G only comes in 4x8' and only in a few colors. Plex folks *say* they'll make bigger sheets for me but I've yet to see them put their money where their mouth is, so to speak. When considering sheet yields, the price difference per sq ft becomes somewhat inconsequential.

HTH,

James

Belgian Anthias

New member

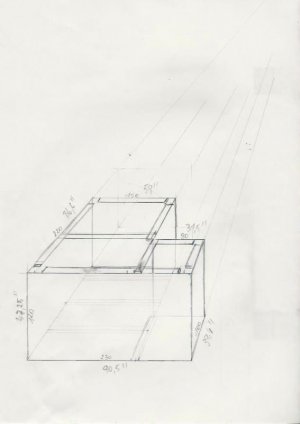

Big acrylic tank diy

Big acrylic tank diy

We are going to build this 47" high tank in plexi GS. For the 2 big windows we are going to use 35mm thick ' about 1 1/2". The other sides are not visible so we think about using 25mm ,1", for these windows and eventualy place braces in the middle. These supporting braces, are they best put verically or horizontal? or both?

For the top euro-brace we want to put the braces on the inside, not on top, because we can not turn the tank to seal them. As they are used against bowing of the pane, must they come in the corners? With glass aqua this is not done to prevent breaking of some glass. We would use 4"w 1" thick acryl for the top bracing. the big centerbrace will be 8" w and the other 4".

For the bottom we think using 20mm +- 3/4"thick acryl pane. The bottom comes on a 1 1/2" thick multiplex sufficiantely supported.

Would this be OK so far?

On the website of plexi-glas ( Evonics) they say we have to use a 2 component solvent to make the seams. In this thread other solvents are used.

Witch solvent is best to do this job.

We are just starting to read this magnificent thread. probably all the answers are already given.

Sincerely Yours

Big acrylic tank diy

We are going to build this 47" high tank in plexi GS. For the 2 big windows we are going to use 35mm thick ' about 1 1/2". The other sides are not visible so we think about using 25mm ,1", for these windows and eventualy place braces in the middle. These supporting braces, are they best put verically or horizontal? or both?

For the top euro-brace we want to put the braces on the inside, not on top, because we can not turn the tank to seal them. As they are used against bowing of the pane, must they come in the corners? With glass aqua this is not done to prevent breaking of some glass. We would use 4"w 1" thick acryl for the top bracing. the big centerbrace will be 8" w and the other 4".

For the bottom we think using 20mm +- 3/4"thick acryl pane. The bottom comes on a 1 1/2" thick multiplex sufficiantely supported.

Would this be OK so far?

On the website of plexi-glas ( Evonics) they say we have to use a 2 component solvent to make the seams. In this thread other solvents are used.

Witch solvent is best to do this job.

We are just starting to read this magnificent thread. probably all the answers are already given.

Sincerely Yours

Attachments

Hmm, I guess I do not follow, what supporting braces? do you have a drawing of such?The other sides are not visible so we think about using 25mm ,1", for these windows and eventualy place braces in the middle. These supporting braces, are they best put verically or horizontal? or both?

Personally, I'd use 1.25" rather than the 1"

Correct, and glued well to the adjacent side.For the top euro-brace we want to put the braces on the inside, not on top, because we can not turn the tank to seal them. As they are used against bowing of the pane, must they come in the corners?

I would recommend at least on more crossbrace if possible. I don't like the idea of a 4" crossbrace for a tank this size, 6-8" is best.We would use 4"w 1" thick acryl for the top bracing. the big centerbrace will be 8" w and the other 4".

no problemFor the bottom we think using 20mm +- 3/4"thick acryl pane. The bottom comes on a 1 1/2" thick multiplex sufficiantely supported.

Depends entirely on how well you can machine your parts and how good the edge preparation is. If you do a good job, either is fine.On the website of plexi-glas ( Evonics) they say we have to use a 2 component solvent to make the seams. In this thread other solvents are used.

Evonics states to use 2-part because they know that most people will not get better than a 50% glue joint. While the 2-part will be better in this regard, it will be filled with tons of bubbles unless you put it through a vacuum or centrifuge. Weld-On 42 helps with this but you will need to buy the applicator gun and static mixing tips.

Please do not pay any attention to Evonics stating that the 2-part is stronger. It is only stronger if annealed which your tank cannot be and is only stronger in the joint itself and has zero bearing on it's adhesion to the acrylic. 2-part adhesive (not annealed) is about on par with a good solvent at 2700-3000PSI which is far above any pressure we will see in hobbyist size tanks - yours included.

I have much bigger tanks in service that are ~20 years old and in public aquariums where they are drained and filled often. Solvent is just fine for this application if you do your part.

I thought you were going to use glass for this?

FWIW: For those not familiar with Plexi-Glas GS, it is the same material is Acrylite GP. Evonics owns Cyro (mfrs of Acrylite) and the European rights to the name "Plexi-Glas"

HTH,

James

hello i got my hands of a few good sized peices of 1.5 in spartech the tank i want to build is 68"x48"x24"high with a 4" 1.25 euro brace do you foresee any problems? gonna be gluing with wo#4 have built a couple small thing but nothing this size and suggestions for me?

thanks in advance

thanks in advance

hello i got my hands of a few good sized peices of 1.5 in spartech the tank i want to build is 68"x48"x24"high with a 4" 1.25 euro brace do you foresee any problems? gonna be gluing with wo#4 have built a couple small thing but nothing this size and suggestions for me?

thanks in advance

Mighty thick material for a tank that size, love it

No problems at all, could use slightly smaller eurobrace if desired but no problems whatsoever with size/material. The only concern I have is many folks have a hard time getting the edges prepped well, thicker material causes more flexing in cutters, but that's about it

For wires on material that size I use twist-ties from Hefty bags or produce section at grocery store. Just strip off the paper with wire strippers or razor blade. Wire is .014" and perfect for these thicknesses.

HTH,

James

Similar threads

- Replies

- 2

- Views

- 740

- Replies

- 4

- Views

- 359

- Replies

- 12

- Views

- 2K