You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acrylic fabrication questions? I can help!

- Thread starter JohnL

- Start date

How many baffles how tall and how far apart are they?

Overall pic

Drain side: top brace is about 2.5" wide, baffle is about 7" from the edge, then about 6" to the next baffle (connected by the filter sock holder,) then 1.5" to the next baffle, about 4" from that is another top brace thats about 4" wide

Return side: top brace is 6" wide, about 13" from the end the baffles/braces start (9" tall then 1.5" and a 13.5" tall thats 1.5" from the bottom followed by a 9" then a 13.5" then another 9")

I think its more than strong enough, but I just wanted some outside input. I know I went a bit overboard, but it was my first DIY acrylic project and I wanted the experience. I learned a lot, and won't be making the same mistakes the next time I have a DIY acrylic project.

Floyd R Turbo

Either busy or sleeping

I make sure the pins are at least in the depth of the acrylic, maybe a tad more.

IMO, this is wrong, and that has also been mentioned several times by James and others throughout this thread. You do not want the pins to go all the way through the joint as it will create a dam, and not allow the solvent bead to get past it, and you risk getting bubbles in the joint as you have to start a new bead at every pin. I'm not saying it won't work, but it is certainly not the best way to do it. You only want the pins inserted into the joint far enough to keep it apart, or about 2mm.

For a thicker piece with some weight to it, you want to make sure that the pin is inserted far enough into the joint such that the weight of the material on the tip of the pin doesn't cause the pin to cause damage to the upper piece (the prepped edge). I started to see this when putting the bottom on a 120 tall which was 48x19x30 and 3/4" walls, the weight pushed down on the tips of the pins and made dents in the prepped bottom edge of the walls. It didn't end up mattering, because the solvent and fillet pretty much took care of it, but it is to be avoided IMO.

Floyd R Turbo

Either busy or sleeping

I think its more than strong enough, but I just wanted some outside input. I know I went a bit overboard, but it was my first DIY acrylic project and I wanted the experience. I learned a lot, and won't be making the same mistakes the next time I have a DIY acrylic project.

Haha yeah it's a never ending learning process man! I think you're fine with the baffle and brace placement you show.

I was told by the plastic retailer, that I could use Weldon 3 to weld Polycarbonate. Is this true? Will it bond to Plexiglas-G. or just go strictly with the polycarbonate. Would it hold together a 25 gal tank?? 1/2'' polycarb.

If PC was the best material to make it out of, everyone would be doing it. I would not even try it.

Also is Plexiglas MC suitable for the building of a skimmer? and or a 40gal sump, 3/8 material?

Skimmer, yes. If you're using extruded tube, that's a whole 'nother discussion (edge prep is tricky)

You can use MC on a sump also, no problems. It just tends to bow more. 3/8" is the minimum wall thickness I use on almost everything I build, mainly because it's only about 10% more expensive so it's totally worth it. IMO the cost difference between cell cast and extruded is not enough to make extruded worth it either.

If you're matching dimensions on a glass 40B I would put on a top euro and consider a crossbrace.

Last edited:

hvacman250

New member

IMO, this is wrong, and that has also been mentioned several times by James and others throughout this thread. You do not want the pins to go all the way through the joint as it will create a dam, and not allow the solvent bead to get past it, and you risk getting bubbles in the joint as you have to start a new bead at every pin. I'm not saying it won't work, but it is certainly not the best way to do it. You only want the pins inserted into the joint far enough to keep it apart, or about 2mm.

For a thicker piece with some weight to it, you want to make sure that the pin is inserted far enough into the joint such that the weight of the material on the tip of the pin doesn't cause the pin to cause damage to the upper piece (the prepped edge). I started to see this when putting the bottom on a 120 tall which was 48x19x30 and 3/4" walls, the weight pushed down on the tips of the pins and made dents in the prepped bottom edge of the walls. It didn't end up mattering, because the solvent and fillet pretty much took care of it, but it is to be avoided IMO.

Can you show any pictures of a joint ready for glue, because I am now confused.

I have only done a few projects, but I lay the back down, with the side panel pointing up at 90*. My 90* jig is on the "inside" of the tank with clamps holding it in place. I have been putting my pins in the front/outside edge and glueing from there, but having to run my bead of WO 4 over the pin.

How can I baely put the pin in and not glue over it unless I pin from the back side? But the back is where my jig is? Should I cut spaces in the jig for the pins?

Floyd R Turbo

Either busy or sleeping

You're doing it exactly the way I do it. Maybe I misunderstood madmike's advice (I know he knows what he is talking about - I just jumped on a response without looking at the username - if that's the case, sorry mike!!).

To me the way I read his advice..."make sure the pins are at least in the depth of the acrylic"...was that you should insert the pins fully such that they poke out the other side of the joint. I didn't want anyone reading this to interpret it as such and think that is the right way to do it, because it will cause you problems.

Yes, you want the pins sticking out of the joint and your solvent needle tip will 'tick' over them as you run the solvent in the joint. The point I'm making here is that you only want the pin inserted into the joint just far enough to keep the joint apart, and allow the solvent bead to cruise along ahead of the needle so that you end up with a nice bubble-free joint, as long as you've prepped, cleaned, and blown off the edges right...

To me the way I read his advice..."make sure the pins are at least in the depth of the acrylic"...was that you should insert the pins fully such that they poke out the other side of the joint. I didn't want anyone reading this to interpret it as such and think that is the right way to do it, because it will cause you problems.

Yes, you want the pins sticking out of the joint and your solvent needle tip will 'tick' over them as you run the solvent in the joint. The point I'm making here is that you only want the pin inserted into the joint just far enough to keep the joint apart, and allow the solvent bead to cruise along ahead of the needle so that you end up with a nice bubble-free joint, as long as you've prepped, cleaned, and blown off the edges right...

hvacman250

New member

You're doing it exactly the way I do it. Maybe I misunderstood madmike's advice (I know he knows what he is talking about - I just jumped on a response without looking at the username - if that's the case, sorry mike!!).

To me the way I read his advice..."make sure the pins are at least in the depth of the acrylic"...was that you should insert the pins fully such that they poke out the other side of the joint. I didn't want anyone reading this to interpret it as such and think that is the right way to do it, because it will cause you problems.

Yes, you want the pins sticking out of the joint and your solvent needle tip will 'tick' over them as you run the solvent in the joint. The point I'm making here is that you only want the pin inserted into the joint just far enough to keep the joint apart, and allow the solvent bead to cruise along ahead of the needle so that you end up with a nice bubble-free joint, as long as you've prepped, cleaned, and blown off the edges right...

Ahh, gotcha. you made me second guess my procedure

What is the consensus on timing: once I lay by back piece, solvent both sides (sticking up in the air), pull pins, etc and finish both joints...how long do I let the joints cure before I flip the piece and glue the front? Is overnight sufficient?

I read in this thread somwhere someone mentioned 2-3 days before flush cutting edges when the piece is completely finished. Agreed?

Floyd R Turbo

Either busy or sleeping

What I have read James post and gone by as a good rule of thumb is 2 to 4 hours before touching/moving, overnight if possible, and 20 hours before routing.

The only time I break this rule is when I'm putting in baffles. I will bond the ends onto the back and leave that for at least overnight, then bond all the baffles in and not touch them for a couple hours (usually 4) and then carefully flip the whole thing and bond one end to the front and let that sit overnight (since it's structural), then bond all the rest of the baffles and the end in succeeding order one right after the other, finishing off on the other end panel and let sit for a day, then flush trim.

The only time I break this rule is when I'm putting in baffles. I will bond the ends onto the back and leave that for at least overnight, then bond all the baffles in and not touch them for a couple hours (usually 4) and then carefully flip the whole thing and bond one end to the front and let that sit overnight (since it's structural), then bond all the rest of the baffles and the end in succeeding order one right after the other, finishing off on the other end panel and let sit for a day, then flush trim.

Haha yeah it's a never ending learning process man! I think you're fine with the baffle and brace placement you show.

If PC was the best material to make it out of, everyone would be doing it. I would not even try it.

Skimmer, yes. If you're using extruded tube, that's a whole 'nother discussion (edge prep is tricky)

You can use MC on a sump also, no problems. It just tends to bow more. 3/8" is the minimum wall thickness I use on almost everything I build, mainly because it's only about 10% more expensive so it's totally worth it. IMO the cost difference between cell cast and extruded is not enough to make extruded worth it either.

If you're matching dimensions on a glass 40B I would put on a top euro and consider a crossbrace.

Thanks Floyd,

The PC was a freebee, Just thought I could use it for a small project.

blakecorcoran

New member

I have not read this entire thread, but at least 100+ pages. Sorry if this is a repetitive question.

I would like to construct a sump (24''Lx24''Wx12''H) out of 1/4'' Acrylite FF. I understand FF is good for Chinese extruded acrylic and bad relative to what I could use. However, I'm deciding between buying a glass tank vs. this option based on budget.

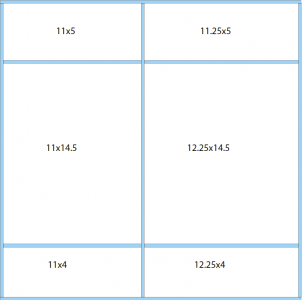

Can I get away with this if the sump will have 9'' water max throughout as well as a 11x14x6'' DSB in one compartment? A rough sketch is attached. I would cement the baffles into place for support. I was about to place the order thinking 1/4'' extruded for a sump holding 9'' H20 with multiple baffles would surely be enough...but then I thought I should see if am wrong. Thank you for the help and for answering so many similar questions.

I would like to construct a sump (24''Lx24''Wx12''H) out of 1/4'' Acrylite FF. I understand FF is good for Chinese extruded acrylic and bad relative to what I could use. However, I'm deciding between buying a glass tank vs. this option based on budget.

Can I get away with this if the sump will have 9'' water max throughout as well as a 11x14x6'' DSB in one compartment? A rough sketch is attached. I would cement the baffles into place for support. I was about to place the order thinking 1/4'' extruded for a sump holding 9'' H20 with multiple baffles would surely be enough...but then I thought I should see if am wrong. Thank you for the help and for answering so many similar questions.

Attachments

blakecorcoran

New member

I'm really tempted to buy the FF...somebody stop me!

Floyd R Turbo

Either busy or sleeping

Check out post #2005 in this thread, Acrylite FF is probably the best extruded material you could use, so if you were going to do this build with 1/4" FF that would be best. But I'm not sure that I would, even though your operating level in the sump will be 9" (which is pretty high actually) you have to figure for the worst case scenario which would be power-off and sump full. At that point, during which you do not want a failure, is where you are putting the maximum stress on the vessel. Will it hold? Maybe, it depends largely on your fabrication technique (i.e. study this thread diligently).

But if it were me, I would build the walls out of 3/8" and put 2" perimeter 1/4" thick eurobrace on the top, but that's just off the top of my head, James might have additional (and more experience-based) advice. All that is for peace of mind knowing that it will have a much higher chance of holding.

Extruded is fine for sumps, it just may bow a little bit more, which would be made up for with the eurobrace to some extent.

The other thing to consider is that your baffles can really only be considered structural if you do them right, IMO. If you build the walls/top/bottom then put the baffle in, they're going to be fit tight (hard to use pins method) so basically tacked in place so they're watertight, or at least mostly, and this doesn't provide the best bond and might break or weaken under stress. What I do is put the baffles in after bonding the sides to the back so I can use pins, then put the front on, then the top/bottom. That comes with it's own set of difficulties, but makes for a better cleaner looking build, and structural bonds. Getting internal baffles perfectly square is kind of a PITA but so is getting anything perfectly square, especially without the right equipment.

HTH

But if it were me, I would build the walls out of 3/8" and put 2" perimeter 1/4" thick eurobrace on the top, but that's just off the top of my head, James might have additional (and more experience-based) advice. All that is for peace of mind knowing that it will have a much higher chance of holding.

Extruded is fine for sumps, it just may bow a little bit more, which would be made up for with the eurobrace to some extent.

The other thing to consider is that your baffles can really only be considered structural if you do them right, IMO. If you build the walls/top/bottom then put the baffle in, they're going to be fit tight (hard to use pins method) so basically tacked in place so they're watertight, or at least mostly, and this doesn't provide the best bond and might break or weaken under stress. What I do is put the baffles in after bonding the sides to the back so I can use pins, then put the front on, then the top/bottom. That comes with it's own set of difficulties, but makes for a better cleaner looking build, and structural bonds. Getting internal baffles perfectly square is kind of a PITA but so is getting anything perfectly square, especially without the right equipment.

HTH

blakecorcoran

New member

Thanks, Floyd. If I pump the FF up to 3/8'', than going glass will be cheaper. Plus, as you said, a lot depends on fabrication techniques, and I have no experience. Sounds like I might need to go glass...I'll keep debating. My lack of experience is both what makes me want to try, and nervous to do so. Good advice RE the baffles for structural support. I had accounted for this before, but forgot...too much to keep straight.

You're doing it exactly the way I do it. Maybe I misunderstood madmike's advice (I know he knows what he is talking about - I just jumped on a response without looking at the username - if that's the case, sorry mike!!).

To me the way I read his advice..."make sure the pins are at least in the depth of the acrylic"...was that you should insert the pins fully such that they poke out the other side of the joint. I didn't want anyone reading this to interpret it as such and think that is the right way to do it, because it will cause you problems.

Yes, you want the pins sticking out of the joint and your solvent needle tip will 'tick' over them as you run the solvent in the joint. The point I'm making here is that you only want the pin inserted into the joint just far enough to keep the joint apart, and allow the solvent bead to cruise along ahead of the needle so that you end up with a nice bubble-free joint, as long as you've prepped, cleaned, and blown off the edges right...

Thanks Floyd and Mike.

If my pieces are flush cut will I still be able to glue from the outside with the pins on the outside and the plastic angles on the inside. Or should I then glue from the inside requiring me to pick up the bottle to go around the angle brackets and then continuing to glue.

Floyd R Turbo

Either busy or sleeping

I can't really say as I've never really tried it that way. I would think that you could do the solvent on the outside and then pull the pins and get it lined up flush, what you lose is the action of the fillet on the outside edge which prevents bubbles from sucking into the joint, that is really the point of the fillet.

What I think would happen is that you would also end up with some solvent running down the edge of the bottom piece you're bonding to when you pull the pins, which is unsightly, but probably doesn't weaken the material. This of course means the solvent you just applied will run out of the joint though. Bubbles in the joint would be what would weaken it, and to what extent would depend on the edge prep technique.

That being said, I've ran across some DIY methods online for building tanks that turned out fine, one comes to mind and it was an "L" shaped tank where they put pieces of black electrical tape on the bottom sticking out, ran the solvent, then pulled the tape up the side of the vertical panel to hold it together. Not the best technique, but it worked for that guy. Who knows if it's still holding water though

What I think would happen is that you would also end up with some solvent running down the edge of the bottom piece you're bonding to when you pull the pins, which is unsightly, but probably doesn't weaken the material. This of course means the solvent you just applied will run out of the joint though. Bubbles in the joint would be what would weaken it, and to what extent would depend on the edge prep technique.

That being said, I've ran across some DIY methods online for building tanks that turned out fine, one comes to mind and it was an "L" shaped tank where they put pieces of black electrical tape on the bottom sticking out, ran the solvent, then pulled the tape up the side of the vertical panel to hold it together. Not the best technique, but it worked for that guy. Who knows if it's still holding water though

IMAMONSTER

New member

Tank Build Need HELP!

Tank Build Need HELP!

Hi everyone im new to this forum. And have some questions about a new tank build. Its 8x3x3 one inch cellcast. I plan on using Weld on 42. Has any one used Weld on 42 and what is the bestway/tricks to Weld when welding sheets this big any special way to do this or process to follow.

IMAMONSTER

Tank Build Need HELP!

Hi everyone im new to this forum. And have some questions about a new tank build. Its 8x3x3 one inch cellcast. I plan on using Weld on 42. Has any one used Weld on 42 and what is the bestway/tricks to Weld when welding sheets this big any special way to do this or process to follow.

IMAMONSTER

Floyd R Turbo

Either busy or sleeping

I would just use solvent, get straight MC and mix in about 5-7% glacial AA and use high flow needles and a few skilled friends and do it with the pins method. The bond strength is better with solvent and you know if it's good right away vs WO40/42 where you have to put it under stress to find out if you did it right. Read through this thread and you'll see IIRC James/Acrylics has stated that he uses solvent for joints up to 2", granted he also mixes in EDC which is a bit harder to get a hold of and expensive, but I would use solvent unless you have some particular reason you want to use 40/42.

For my external overflow I had my pieces cut to the exact dimensions. So my plan was to have the 3 sides sitting on top of the bottom piece. Therefore, my pieces cut was using 3/8" material:

Bottom=30"x5"

Two Sides= 4 5/8" x 6"

Front = 30" x 6"

Since this is looking difficult to get a clean joint when the pieces were cut to be flush, I'm going to have to make my overflow slightly smaller so I can get the 1/16" excess on the outer edges which will be routed flush afterward.

So my question is how do I flush out the left and right sides to match the bottom piece on the open ended side that will attach to the tank?

So basically, what I'm asking is if I'm making an external overflow that has a bottom, front, and two sides (left and right), how do I get the left and right pieces to be flush with the bottom piece on the edge that will attach to the tank? Do I simply line it up flush when I glue. Because I can't see how this edge will be flush trimmed afterward.

Bottom=30"x5"

Two Sides= 4 5/8" x 6"

Front = 30" x 6"

Since this is looking difficult to get a clean joint when the pieces were cut to be flush, I'm going to have to make my overflow slightly smaller so I can get the 1/16" excess on the outer edges which will be routed flush afterward.

So my question is how do I flush out the left and right sides to match the bottom piece on the open ended side that will attach to the tank?

So basically, what I'm asking is if I'm making an external overflow that has a bottom, front, and two sides (left and right), how do I get the left and right pieces to be flush with the bottom piece on the edge that will attach to the tank? Do I simply line it up flush when I glue. Because I can't see how this edge will be flush trimmed afterward.

Last edited:

Floyd R Turbo

Either busy or sleeping

I am building one exactly as you describe right now. The sides and back have the same (vertical) dimension. You bond the sides to the back, leaving the lip, let sit overnight (20 hours if you can) and flush trim. Then you bond the bottom to that assembly and after you pull the pins, you adjust the pieces such that the sides and bottom that will bond to the back of the tank are lined up. I do this by running my fingernail back and forth to see if there is a 'lip' I can feel, and adjust the top piece accordingly until there is no lip. The trick is doing this at the same time at both points without rotating the back/sides assembly and putting the other point out of alignment, and you only have about 15 seconds or so to do this (maybe 30) after pulling the pins.

After that, you flush trim the bottom piece along the sides and back. I think you were trying to think of how to flush trim the edge that you bond to the tank, which you don't do.

HTH.

After that, you flush trim the bottom piece along the sides and back. I think you were trying to think of how to flush trim the edge that you bond to the tank, which you don't do.

HTH.

Similar threads

- Replies

- 2

- Views

- 721

- Replies

- 2

- Views

- 299

- Replies

- 12

- Views

- 2K