ExitTrauma

Member

Hello all.

This is my journal for my new build. I’ve been keeping reefs for most of my life off and on. I’m sure everyone knows how it goes. My last two tanks ended in total catastrophe so I got fed up and dumped everything into storage.

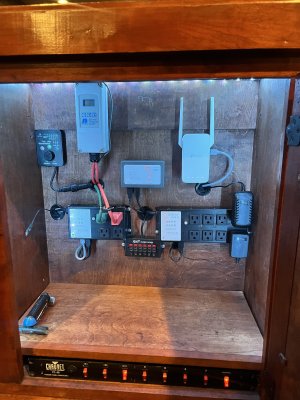

That was around a decade ago. Now, I’ve decided that i want another build. I’m looking for something simple. I had a RO/di setup but sold that and really just looking to handle everything with store bought water. This build, I’m looking for simplicity. My last tank changed its own water through the apex, and the entire thing was basically a Rube Goldberg device. I’m looking for the opposite of that lol.

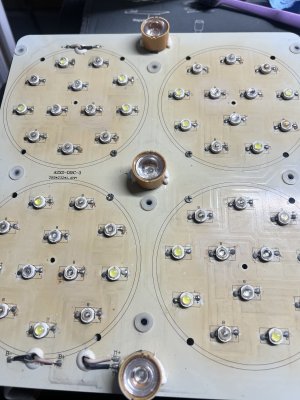

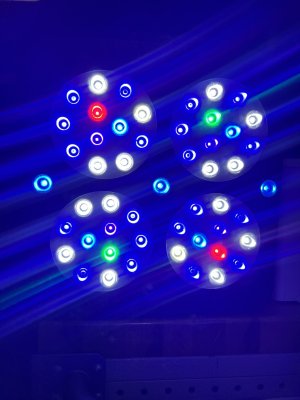

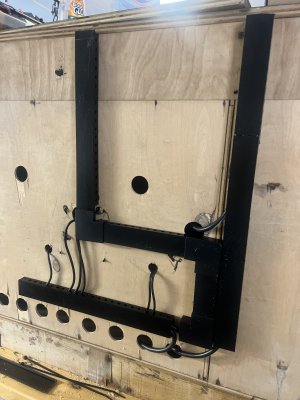

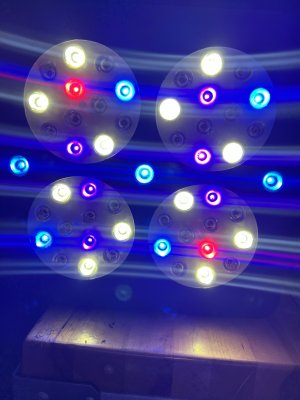

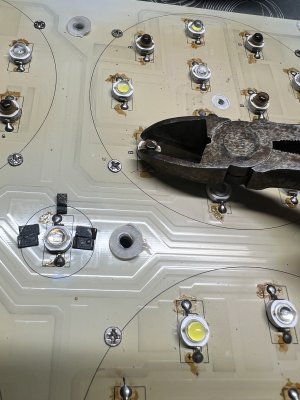

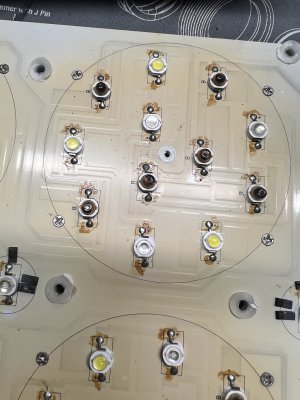

I went through all my old gear and have been cleaning it up. First up is the light, I attached all the pics of the progress pics. Spoiler alert, the light has broken LEDs lol. So basically I wasted a day and a half cleaning it up. I have another one that seems to have all the diodes working but the controller on the front seems to be broken. I’ll tear that one down and clean it and see if I can get it functional.

I know what you’re thinking. “Hey fellow reef enthusiast. Why don’t you just buy new equipment?”

Well, allow me to retort.

“Why, fellow forum goer, would I do that, when I can do 10x the work for half the result? Or even, as we see here, for no result?”

If that makes no sense, then feel free to join my wife with that slow disappointed head shake that she does.

It seems as though the acrylic lens over the diode melted and left the lens brittle. So I pulled the domes off in hopes that the bulbs functioned but were just blocked from the opaque dome. Unfortunately that was not the case.

This is my journal for my new build. I’ve been keeping reefs for most of my life off and on. I’m sure everyone knows how it goes. My last two tanks ended in total catastrophe so I got fed up and dumped everything into storage.

That was around a decade ago. Now, I’ve decided that i want another build. I’m looking for something simple. I had a RO/di setup but sold that and really just looking to handle everything with store bought water. This build, I’m looking for simplicity. My last tank changed its own water through the apex, and the entire thing was basically a Rube Goldberg device. I’m looking for the opposite of that lol.

I went through all my old gear and have been cleaning it up. First up is the light, I attached all the pics of the progress pics. Spoiler alert, the light has broken LEDs lol. So basically I wasted a day and a half cleaning it up. I have another one that seems to have all the diodes working but the controller on the front seems to be broken. I’ll tear that one down and clean it and see if I can get it functional.

I know what you’re thinking. “Hey fellow reef enthusiast. Why don’t you just buy new equipment?”

Well, allow me to retort.

“Why, fellow forum goer, would I do that, when I can do 10x the work for half the result? Or even, as we see here, for no result?”

If that makes no sense, then feel free to join my wife with that slow disappointed head shake that she does.

It seems as though the acrylic lens over the diode melted and left the lens brittle. So I pulled the domes off in hopes that the bulbs functioned but were just blocked from the opaque dome. Unfortunately that was not the case.

Attachments

-

IMG_3236.jpeg2.2 MB · Views: 126

IMG_3236.jpeg2.2 MB · Views: 126 -

IMG_3276.jpeg1.4 MB · Views: 124

IMG_3276.jpeg1.4 MB · Views: 124 -

IMG_3265.jpeg2.4 MB · Views: 117

IMG_3265.jpeg2.4 MB · Views: 117 -

IMG_3245.jpeg1.5 MB · Views: 120

IMG_3245.jpeg1.5 MB · Views: 120 -

IMG_3242.jpeg1.2 MB · Views: 113

IMG_3242.jpeg1.2 MB · Views: 113 -

IMG_3241.jpeg1.5 MB · Views: 109

IMG_3241.jpeg1.5 MB · Views: 109 -

IMG_3240.jpeg2.5 MB · Views: 121

IMG_3240.jpeg2.5 MB · Views: 121 -

IMG_3239.jpeg2.3 MB · Views: 109

IMG_3239.jpeg2.3 MB · Views: 109 -

IMG_3238.jpeg2.3 MB · Views: 119

IMG_3238.jpeg2.3 MB · Views: 119 -

IMG_3237.jpeg2.2 MB · Views: 123

IMG_3237.jpeg2.2 MB · Views: 123