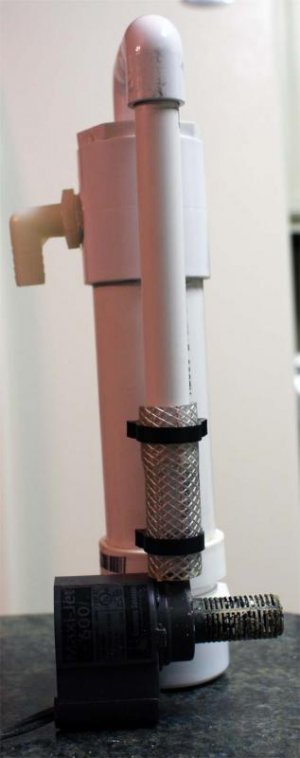

With all of the fuss over biopellets, I decided to try them out.

I'm not claiming to be an early adopter or the first person to DIY such a reactor -- I'm just sharing some picts to help others decide if they want to save a few bucks and make their own.

Yes, a $40 TLF reactor looks better -- hell, you can even see the pellets moving around in it.

Function was priority. It's in my sump. It looks ok, but it's not going to win any beauty pageants.

That said, here we go...

I'm not claiming to be an early adopter or the first person to DIY such a reactor -- I'm just sharing some picts to help others decide if they want to save a few bucks and make their own.

Yes, a $40 TLF reactor looks better -- hell, you can even see the pellets moving around in it.

Function was priority. It's in my sump. It looks ok, but it's not going to win any beauty pageants.

That said, here we go...