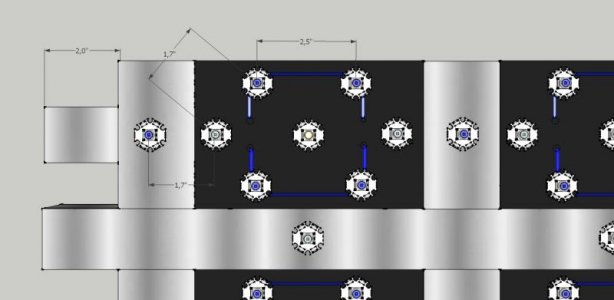

I don't want to overdo the blue LEDs so was thinking of not using optics in the aim of getting more spread.

It may sound contradictory, but it seems the RBs don't reach that far down without optics. They - China - gave me 30/40 degree optics instead of 80 degrees and the spotlight effect was clearly visible, as you can see in the picture, so I pulled them off after a few days and that's when I noticed it.

I have a big Nephthea close to the front reaching halfway towards the centre of the tank (the pink softcoral)

In the picture, the optics were still on the LEDs, and there's a little color difference between the top of the coral and the part near the bottom.

Without the optics the part near the bottom looks a lot more brownish like the top left side of the coral.

So I thought that could be due to the XM-Ls which I am using. They are @ 800mA while the RBs are @ 750mA. Dailing down the XM-Ls didn't help much, and dispite the fact that the front row consists of royal blues, like the picture shows, the difference was still clearly visible.

So you might try the RBs without optics, but make sure you have them around when you need them.

Attachments

Last edited: