Nice work DreamLand!

You may want to consider enclosing the motor as the saltwater environment will make quick work of the metals used on these motors.

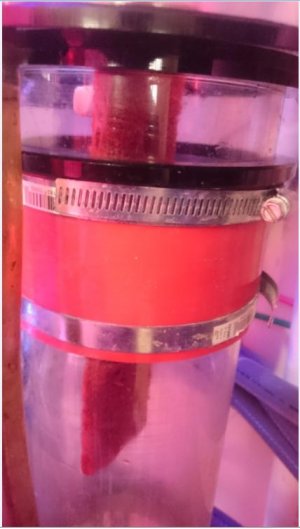

Here's mine which includes a freshwater wash down (I've since changed the micro jets to ones without valves) and a salad bowl dome mod to increase foam height and direct the skim toward the cup rather the flat top of the lid. I just used a rubber pipe cap as the enclosure for quick and easy motor replacement if needed.

You may want to consider enclosing the motor as the saltwater environment will make quick work of the metals used on these motors.

Here's mine which includes a freshwater wash down (I've since changed the micro jets to ones without valves) and a salad bowl dome mod to increase foam height and direct the skim toward the cup rather the flat top of the lid. I just used a rubber pipe cap as the enclosure for quick and easy motor replacement if needed.