Maryland Guppy

New member

ya.....that is why i suck at it. i read that and get all confused im a DIYer with just enough electronics knowledge to screw something up good

You could check out some of the TI datasheets for there drivers.

A longer document from TI with calculation examples.

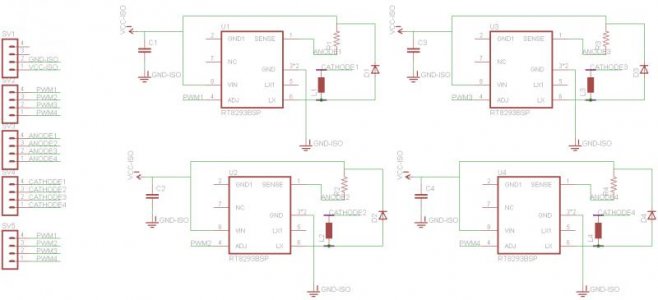

I was driving for a very low part count so no TI drivers.

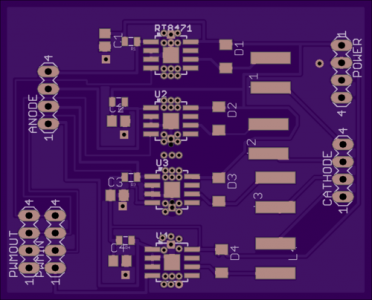

I have not etched a copper board since 1984.

It was a frequency counter with like a 9 digit display.

All through hole components at that.

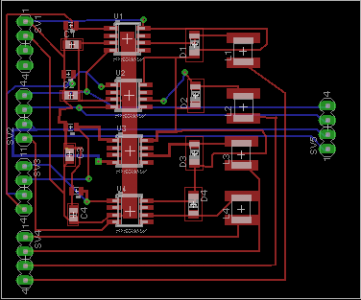

Now I have to rethink surface mount devices and configuration.

I have been researching for about 1 year now and am ready.

Up until now I have been using all LDD drivers on boards with sockets.

LDD's cost $6 each, I can build a driver for $2.31 each plus cost of boards.

I may not save money when it's done but it keeps my brain ticking.

I belong to many forums, most inspired with DIY from several people here.

I am an AutoCAD geek since version 8 I think on 5.25 floppies.

No one wants to build a board from ACAD files though.