TheRealRuk

New member

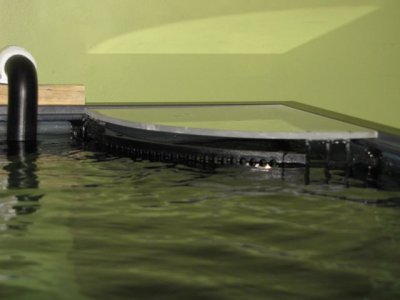

As the title states, this is my post build thread. The tank has been up and running for about 8 months. I value and appreciate everyone's experience and comments (especially moving forward) and as you'll see (and probably already know from your own experience) my tank seams to be ever evolving. I think I've completely redone my sump 3 times, the entire aqua-scaping twice, and plan to redo the returns next, then the canopy, then the... I should have started this a long time ago, but I'm a little behind in the art of doing our tanks justice with a camera. Being very new and inexperienced when I (and the wife) set it up; I hope by posting some of my mistakes, I can save someone unnecessary aggravation.

Prior to setting up this tank, my wife, scratch that... Santa got me a 24g Aquapod for ChrisTmas 2 years ago. We did okay but were having problems keeping some of the coral alive long term. We figured it was the lights and instead of popping a couple hundred on decent lights decided to upgrade the system all together... The next short sequence of events was a blur and somehow we ended up going from a 24g to a 150g. During this experience I learned:

Lesson #1, as much as my wife plays the voice of reason when it comes to the reef budget; when she's in the local fish shop, the sky's the limit...

The real reason we were having so much trouble was the digital thermometer we had was ten degrees off... The tank was running in the 90's; which led to:

Lesson #2, Redundant thermometers or temp probes...

My name is Matt, this is my story... and I'm sticking to it.

Prior to setting up this tank, my wife, scratch that... Santa got me a 24g Aquapod for ChrisTmas 2 years ago. We did okay but were having problems keeping some of the coral alive long term. We figured it was the lights and instead of popping a couple hundred on decent lights decided to upgrade the system all together... The next short sequence of events was a blur and somehow we ended up going from a 24g to a 150g. During this experience I learned:

Lesson #1, as much as my wife plays the voice of reason when it comes to the reef budget; when she's in the local fish shop, the sky's the limit...

The real reason we were having so much trouble was the digital thermometer we had was ten degrees off... The tank was running in the 90's; which led to:

Lesson #2, Redundant thermometers or temp probes...

My name is Matt, this is my story... and I'm sticking to it.