I'm in the beginning stages of planning a 75 gal build. I've done some stand plans and plumbing plans and it's time to check my work. I've attached some renderings in the thread and I'd like to get some feedback on what you all think. If you see anything missing, or if there's a better way, please chime in. I'd rather take the advice/criticism now and build it right the first time

Equipment I already have from a previous build is a Trigger Systems sump, an Eheim 1262 return pump, BRS reactor (I'll be adding a second for GFO), Apex w/ various IO's, Tunze ATO, a VorTec MP10 (I'll be adding a second), and some Marine Pure.

Equipment I need to get and would like some suggestions on are heaters (I want to replace the one I have with dual, more reliable heaters), a skimmer, an overflow (planning on using Reef Saavy), lighting (Leaning towards two or three Kessil A360W) and anything else I might be missing.

The previous build was a 55 gal freshwater tank and was really to test out the sump, Apex, and some other things I had never done before. I'm moving so I had to break that down, but now that the testing is out of the way, it's on to a bigger set up. I do plan to start FOWLR and get maintenance schedules down, the tank stable, etc, before approaching corals.

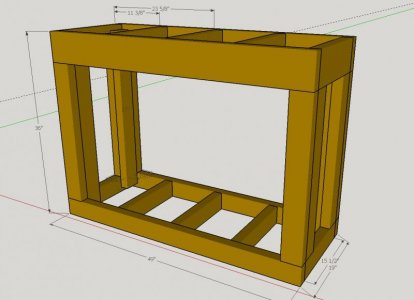

Pics are attached. I couldn't get embedded links to work from dropbox or google photos. The stand is the Rocket design.

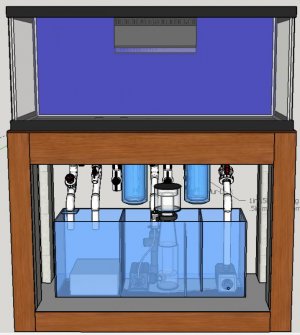

Next is a front and rear view of the whole set up.

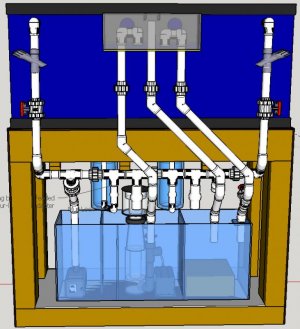

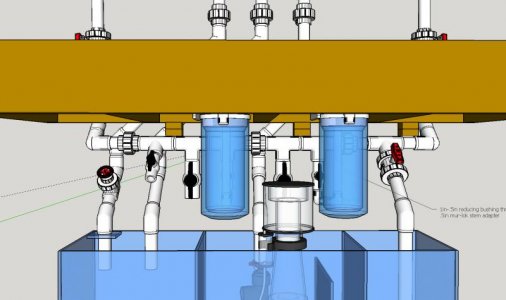

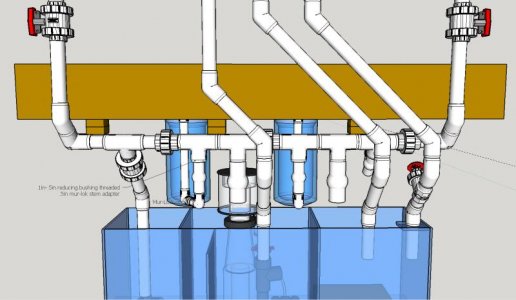

The last two are close ups of the Plumbing. All pipe is 1in. You can see the three drains, one with a gate valve. The main drain has a filter sock on it. I plan to use some silicone tubing to connect the return pump to the PVC though it's not shown. The manifold from left to right is:

Spare 0.5in mur-lok valve, spare 1in PVC valve, 0.5in mur-lok valve for GFO reactor, spare 1in PVC valve, 0.5in mur-lok valve for carbon reactor, and return valve.

There are valves for each of the return lines along with Wye check valves. Unions are in positions I think would make the whole thing easy to disassemble and clean/repair when needed. You can also see some blocking I plan to use to attach the PVC to the frame for support. Anyone have anything they use for this that works well?

Some questions I have on the setup:

Bulkheads - for the return bulkheads, is there a way to plumb them so they can be removed if they ever need to be? If I glue a fitting on the back, how will it will pull through the hole in the glass. Are threaded bulkheads reliable for connecting plumbing? I could also be totally missing something...

Overflow - is it necessary to have the full siphon elbow just a little lower than the secondary drain? I'm not showing the air inlet on the secondary drain, but I know it needs to be there. Is there a guideline for how high the emergency drain should sit?

Possible Additions - I have some spare valves built into the manifold. Not sure what I will use them for, but one idea is to use one as a drain for water changes. I could theoretically open it to drain and use another pump to put water back in at the same time while keeping everything running. I also might use the spares to help circulate water in the sump sections to keep detritus off the bottom. If I go that route, I may change the 1in spares to mur-lok.

I don't show the ATO tank yet. It's in a yet to be drafted side addition to the stand. I'm thinking one side will hold ATO, chemicals, parts, etc, and the other side will hold electrical.

Anyone else have anything fun they have in their plumbing set ups?

Anyway, that's all I've got for now. Hopefully I'm not too far off with the design. I appreciate the help!

Equipment I already have from a previous build is a Trigger Systems sump, an Eheim 1262 return pump, BRS reactor (I'll be adding a second for GFO), Apex w/ various IO's, Tunze ATO, a VorTec MP10 (I'll be adding a second), and some Marine Pure.

Equipment I need to get and would like some suggestions on are heaters (I want to replace the one I have with dual, more reliable heaters), a skimmer, an overflow (planning on using Reef Saavy), lighting (Leaning towards two or three Kessil A360W) and anything else I might be missing.

The previous build was a 55 gal freshwater tank and was really to test out the sump, Apex, and some other things I had never done before. I'm moving so I had to break that down, but now that the testing is out of the way, it's on to a bigger set up. I do plan to start FOWLR and get maintenance schedules down, the tank stable, etc, before approaching corals.

Pics are attached. I couldn't get embedded links to work from dropbox or google photos. The stand is the Rocket design.

Next is a front and rear view of the whole set up.

The last two are close ups of the Plumbing. All pipe is 1in. You can see the three drains, one with a gate valve. The main drain has a filter sock on it. I plan to use some silicone tubing to connect the return pump to the PVC though it's not shown. The manifold from left to right is:

Spare 0.5in mur-lok valve, spare 1in PVC valve, 0.5in mur-lok valve for GFO reactor, spare 1in PVC valve, 0.5in mur-lok valve for carbon reactor, and return valve.

There are valves for each of the return lines along with Wye check valves. Unions are in positions I think would make the whole thing easy to disassemble and clean/repair when needed. You can also see some blocking I plan to use to attach the PVC to the frame for support. Anyone have anything they use for this that works well?

Some questions I have on the setup:

Bulkheads - for the return bulkheads, is there a way to plumb them so they can be removed if they ever need to be? If I glue a fitting on the back, how will it will pull through the hole in the glass. Are threaded bulkheads reliable for connecting plumbing? I could also be totally missing something...

Overflow - is it necessary to have the full siphon elbow just a little lower than the secondary drain? I'm not showing the air inlet on the secondary drain, but I know it needs to be there. Is there a guideline for how high the emergency drain should sit?

Possible Additions - I have some spare valves built into the manifold. Not sure what I will use them for, but one idea is to use one as a drain for water changes. I could theoretically open it to drain and use another pump to put water back in at the same time while keeping everything running. I also might use the spares to help circulate water in the sump sections to keep detritus off the bottom. If I go that route, I may change the 1in spares to mur-lok.

I don't show the ATO tank yet. It's in a yet to be drafted side addition to the stand. I'm thinking one side will hold ATO, chemicals, parts, etc, and the other side will hold electrical.

Anyone else have anything fun they have in their plumbing set ups?

Anyway, that's all I've got for now. Hopefully I'm not too far off with the design. I appreciate the help!