Raul-7

Member

Let me start by saying the software is fool-proof, so easy a cave man can do it...But the PL is the controller's Achilles-heel.

Is there any plans to revamp it and make it more understandable?

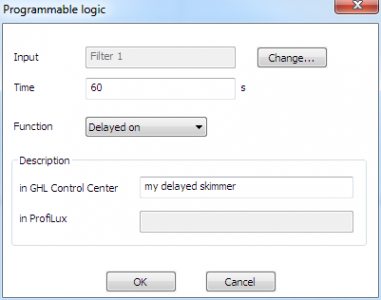

It would be invaluable as it would allow the user to add max on times for drain and fill [AWC] or delay the skimmer after a feed cycle.

Is there any plans to revamp it and make it more understandable?

It would be invaluable as it would allow the user to add max on times for drain and fill [AWC] or delay the skimmer after a feed cycle.