IUfan

Member

Trying to come up with a way to place a QT tank in my fish room without needing another stand for it to sit on.

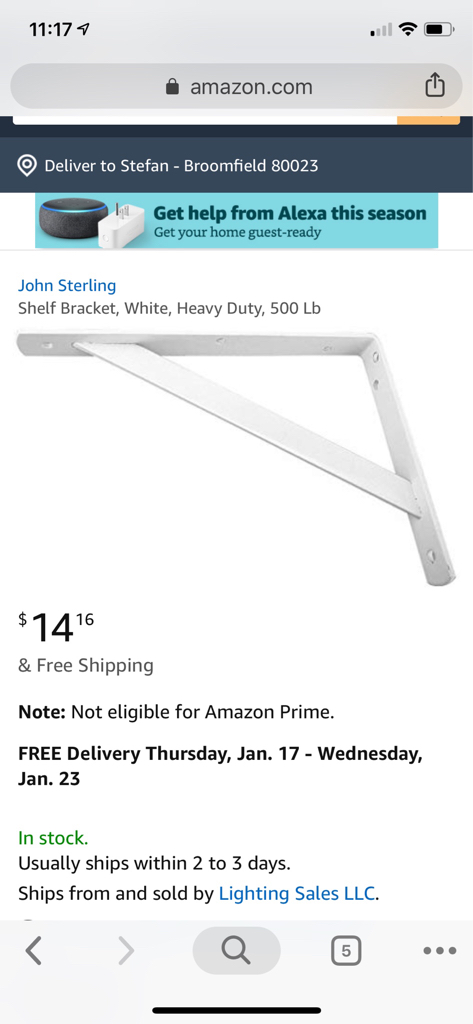

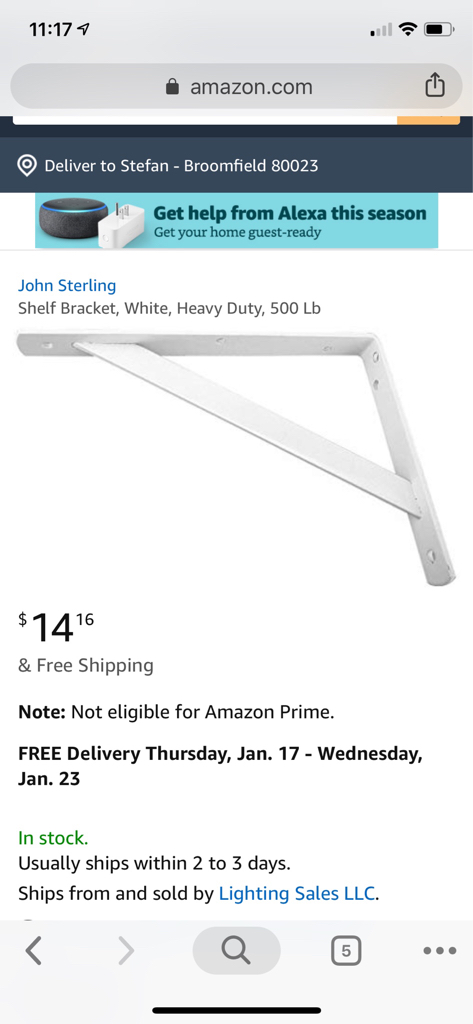

Was thinking of using 2 of these heavy duty shelf brackets and then some 1/2" plywood as the shelf.

It says it can handle 500lbs (x2 should be 1000lbs) but I am still concerned, just worries me for some reason. Would be on a studded wall, so each bracket will be mounted into a 2x4 stud. Can the wall handle this?

The qt tank would be a small 10 gallon tank, 20"x10.5"x11".

Thoughts?

Sent from my iPhone using Tapatalk

Was thinking of using 2 of these heavy duty shelf brackets and then some 1/2" plywood as the shelf.

It says it can handle 500lbs (x2 should be 1000lbs) but I am still concerned, just worries me for some reason. Would be on a studded wall, so each bracket will be mounted into a 2x4 stud. Can the wall handle this?

The qt tank would be a small 10 gallon tank, 20"x10.5"x11".

Thoughts?

Sent from my iPhone using Tapatalk

Last edited: