saltwatershark

New member

Hey everyone, I'm starting a new thread on my current reef project that I started planning a couple years ago, but only recently began implementing. Based on a borderline obsessive compulsive set of plans that kept me up for many nights, I decided to start putting those plans in place: I recently pulled the trigger and started the build. Depending on everyone's level of interest, I'll post more information and pics as they arise.

I have experience with saltwater fish keeping generally, but nothing of this magnitude. I got thoroughly hooked on saltwater reef keeping because I have an hour long commute each way to/from work everyday, and I started listening (on YouTube) to American Reef, NY Steelo, Jim Stime LA Fish Guy, Ryan at Bulk Reef Supply, and Dave at Vivid Aquariums. These guys got me hooked!

Anyhow, here are the basics of what I have in process:

1. 715 Gallon Display Tank (DT). The DT will be on the main floor of my home in the hearth room. This room is connected to my kitchen and is where my family spends the lion's share of time together. I selected this location in consultation with my wife because we want to maximize our family's enjoyment. Other locations were considered but ultimately this place looked best and structurally it is appealing (see discussion below). The DT will be approximately 715 gallons and measure 144" (l) x 31" (w) x 37.5" (h). I have not ordered the DT tank because I want to make more progress on the fish room before ordering the DT, and I have to remove a built in desk and cabinets.

2. Glass Versus Acrylic. I decided on 3/4" starphire glass for the front and sides, and standard grade 3/4" glass for the bottom and back. I want the DT to be as close to "scratch free" as possible, and I want the extra thick glass to make it super strong. I have 3 little kids that love to bang toys on everything so having this thickness should help. The starphire glass, while adding significantly to the overall cost, will make this tank a transparent as possible. I respect acrylic tank people, but if my little kids scratch a tank of this size (and expense) i might go over the edge!

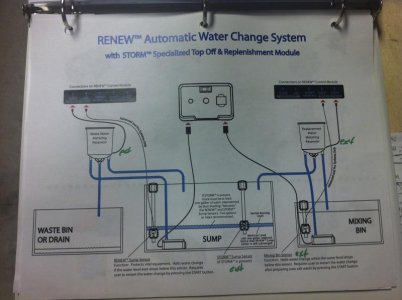

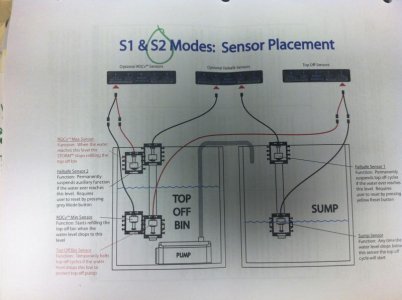

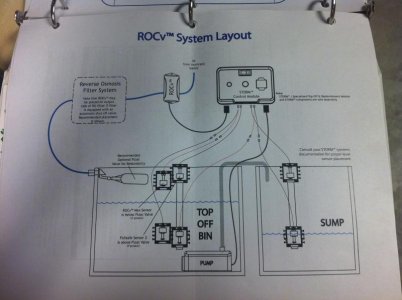

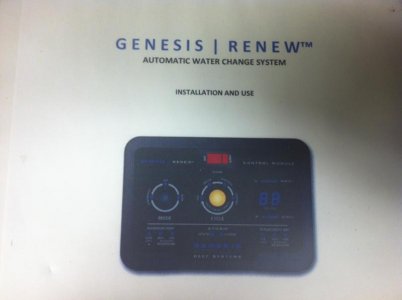

3. Downstairs Fish Room. Our basement is only partially finished. We live in a small community called Saint Albans which is near Saint Louis, Missouri. Basements are standard to prevent home plumbing from freezing. Directly underneath the hearth room (where the DT will be installed) is an unfinished room that my son calls "Daddy's Workshop." I keep my tools, pool supplies, and now the sump and filtration components here. Water will drain from the DT overflows and empty into the sump downstairs. The sump is a 240 gallon glass tank that has been drilled and fitted with 9 bulkheads (7 are 1" and 2 are 1.5"). I had numerous glass dividers cut to specification, which I will silicone into place upon finalization of the sump design. The sump is connected to two reservoirs, each are 150 gallons. One of the reservoirs will hold RO/DI water for auto top off (ATO) purposes and the other reservoir will hold saltwater for water change purposes. I added a saltwater mixing station that feeds into the saltwater reservoir based on another posting that I have found to be quite inspirational (see "Triple S Fish Ranch" thread which is an amazing thread). I tied the reservoirs into the sump with a Genesis reef ATO and water changing system has been installed. Also connected to the sump is a 29 gallon aquarium that has been drilled and fitted with 3 bulkheads (1" each). This will be an acclimation tank when no fish or corals are obtained, or as a frag growing tank when new fish are not in quarantine. It can be tied into the sump or segregated with the simple turn of a calve. I may add more tank volume downstairs if needed, but for now it'll suffice. The nice thing about having the fish room is that it is expandable based upon needs.

4. Plumbing. Piping, true union ball valves, gate valves, T's, Wyes, 45's, L's, check valves and other fittings are Schedule 80 PVC for all fittings. Valves are either Cepex true union ball valves (TUBV) or Spears industrial gate valves. They serve different functions but I greatly prefer the

TUBVs because they are much easier to turn. I plan to run the return pipes through the floor in between the walls with only the ends emerging from the wall and tying into the DT bulkheads.

5. Other Filtration. The system includes UV sterilization (150 watt high output smart UV by Emperor Aquatics), ozone generator with air dryer and O3 reactor, carbon reactor, GFO reactor, protein skimmer, and 2-part doser. A refugium will be built into the sump. All reactors and the skimmer are external to the sump to maximize water volume. I have not selected a heater or determined if a chiller will be needed.

6. Water Pumps. The return pumps are 2 Reeflo hammerhead gold pumps which produce about 3000-3500 gallons per hour (GPH) a piece. In addition there are 2 Reeflo blowhole 840s and 1 Reeflo 1140. Each of these pumps is external and hard plumbed to the sump. I'm also considering a Sicce 2400 GPH submersible pump which will power the acclimation tank. A separate canister filter will be hooked into the acclimation tank but will only run when new fish are quarantined. Upstairs in the DT the Reeflo hammerheads will deliver 6000-7000 GPH through 6 inlets: two will be on oscillating sea swirls, and 4 will alternate through an "oceans motions" current divertor. I'm debating what else is needed but I'm thinking a couple Vortech MP60s with battery backups. Not sure yet about the Vortechs but I've heard they're great.

7. Lighting. I need lights upstairs over the DT and a light over the refugium downstairs. I want everything to be LED based on LED unit size, long term operating cost, and heat production and disbursement. Given the depth of the DT (37") I think LED pendants are needed but I'm not yet sure. I'm leaning towards the ecoxotic 100 watt cannon, the ecoxotic 120 watt cannons, or the orphek 110 watt DIF-XP pendant. I need to conduct more research regarding light dispersal, coverage, color, and PAR levels. The refugium LED can be less precise because all I need it to do is grow macro algae 24/7 as a nutrient export strategy.

8. Structural Considerations. A 715 gallon aquarium-- 144" (L) x 31" (W) x 37" (H)-- on the first floor of my home begs the question whether the floor cAn hold the weight. With water, rocks and stand, the tank will weigh around 8000-9000 lbs. (or more). That's like parking 2 suburbans in your family room, but stacking them one on top of the other and condensing all of that weight and spreading it accords a much smaller area. The DT will run across 9 floor joists, with the cement foundation wall on one side, an "I-Beam" directly underneath the full length of the aquarium, with one metal upright/floor jack connecting the I-beam to the foundation floor. I'm also adding 4 foot sections to each side of the existing 2x12 floor joists and then running additional floor jacks from a new cross beam down to the foundation. My wife will kill me if I destroy our new home, and she does not want a new staircase to be added Asa result of the tank falling through the floors. Pictures are attached.

There's a whole lot more to discuss and I really hope everyone jumps in and provides their advice and opinion. This forum is loaded with valuable information-- what a great resource!

I have experience with saltwater fish keeping generally, but nothing of this magnitude. I got thoroughly hooked on saltwater reef keeping because I have an hour long commute each way to/from work everyday, and I started listening (on YouTube) to American Reef, NY Steelo, Jim Stime LA Fish Guy, Ryan at Bulk Reef Supply, and Dave at Vivid Aquariums. These guys got me hooked!

Anyhow, here are the basics of what I have in process:

1. 715 Gallon Display Tank (DT). The DT will be on the main floor of my home in the hearth room. This room is connected to my kitchen and is where my family spends the lion's share of time together. I selected this location in consultation with my wife because we want to maximize our family's enjoyment. Other locations were considered but ultimately this place looked best and structurally it is appealing (see discussion below). The DT will be approximately 715 gallons and measure 144" (l) x 31" (w) x 37.5" (h). I have not ordered the DT tank because I want to make more progress on the fish room before ordering the DT, and I have to remove a built in desk and cabinets.

2. Glass Versus Acrylic. I decided on 3/4" starphire glass for the front and sides, and standard grade 3/4" glass for the bottom and back. I want the DT to be as close to "scratch free" as possible, and I want the extra thick glass to make it super strong. I have 3 little kids that love to bang toys on everything so having this thickness should help. The starphire glass, while adding significantly to the overall cost, will make this tank a transparent as possible. I respect acrylic tank people, but if my little kids scratch a tank of this size (and expense) i might go over the edge!

3. Downstairs Fish Room. Our basement is only partially finished. We live in a small community called Saint Albans which is near Saint Louis, Missouri. Basements are standard to prevent home plumbing from freezing. Directly underneath the hearth room (where the DT will be installed) is an unfinished room that my son calls "Daddy's Workshop." I keep my tools, pool supplies, and now the sump and filtration components here. Water will drain from the DT overflows and empty into the sump downstairs. The sump is a 240 gallon glass tank that has been drilled and fitted with 9 bulkheads (7 are 1" and 2 are 1.5"). I had numerous glass dividers cut to specification, which I will silicone into place upon finalization of the sump design. The sump is connected to two reservoirs, each are 150 gallons. One of the reservoirs will hold RO/DI water for auto top off (ATO) purposes and the other reservoir will hold saltwater for water change purposes. I added a saltwater mixing station that feeds into the saltwater reservoir based on another posting that I have found to be quite inspirational (see "Triple S Fish Ranch" thread which is an amazing thread). I tied the reservoirs into the sump with a Genesis reef ATO and water changing system has been installed. Also connected to the sump is a 29 gallon aquarium that has been drilled and fitted with 3 bulkheads (1" each). This will be an acclimation tank when no fish or corals are obtained, or as a frag growing tank when new fish are not in quarantine. It can be tied into the sump or segregated with the simple turn of a calve. I may add more tank volume downstairs if needed, but for now it'll suffice. The nice thing about having the fish room is that it is expandable based upon needs.

4. Plumbing. Piping, true union ball valves, gate valves, T's, Wyes, 45's, L's, check valves and other fittings are Schedule 80 PVC for all fittings. Valves are either Cepex true union ball valves (TUBV) or Spears industrial gate valves. They serve different functions but I greatly prefer the

TUBVs because they are much easier to turn. I plan to run the return pipes through the floor in between the walls with only the ends emerging from the wall and tying into the DT bulkheads.

5. Other Filtration. The system includes UV sterilization (150 watt high output smart UV by Emperor Aquatics), ozone generator with air dryer and O3 reactor, carbon reactor, GFO reactor, protein skimmer, and 2-part doser. A refugium will be built into the sump. All reactors and the skimmer are external to the sump to maximize water volume. I have not selected a heater or determined if a chiller will be needed.

6. Water Pumps. The return pumps are 2 Reeflo hammerhead gold pumps which produce about 3000-3500 gallons per hour (GPH) a piece. In addition there are 2 Reeflo blowhole 840s and 1 Reeflo 1140. Each of these pumps is external and hard plumbed to the sump. I'm also considering a Sicce 2400 GPH submersible pump which will power the acclimation tank. A separate canister filter will be hooked into the acclimation tank but will only run when new fish are quarantined. Upstairs in the DT the Reeflo hammerheads will deliver 6000-7000 GPH through 6 inlets: two will be on oscillating sea swirls, and 4 will alternate through an "oceans motions" current divertor. I'm debating what else is needed but I'm thinking a couple Vortech MP60s with battery backups. Not sure yet about the Vortechs but I've heard they're great.

7. Lighting. I need lights upstairs over the DT and a light over the refugium downstairs. I want everything to be LED based on LED unit size, long term operating cost, and heat production and disbursement. Given the depth of the DT (37") I think LED pendants are needed but I'm not yet sure. I'm leaning towards the ecoxotic 100 watt cannon, the ecoxotic 120 watt cannons, or the orphek 110 watt DIF-XP pendant. I need to conduct more research regarding light dispersal, coverage, color, and PAR levels. The refugium LED can be less precise because all I need it to do is grow macro algae 24/7 as a nutrient export strategy.

8. Structural Considerations. A 715 gallon aquarium-- 144" (L) x 31" (W) x 37" (H)-- on the first floor of my home begs the question whether the floor cAn hold the weight. With water, rocks and stand, the tank will weigh around 8000-9000 lbs. (or more). That's like parking 2 suburbans in your family room, but stacking them one on top of the other and condensing all of that weight and spreading it accords a much smaller area. The DT will run across 9 floor joists, with the cement foundation wall on one side, an "I-Beam" directly underneath the full length of the aquarium, with one metal upright/floor jack connecting the I-beam to the foundation floor. I'm also adding 4 foot sections to each side of the existing 2x12 floor joists and then running additional floor jacks from a new cross beam down to the foundation. My wife will kill me if I destroy our new home, and she does not want a new staircase to be added Asa result of the tank falling through the floors. Pictures are attached.

There's a whole lot more to discuss and I really hope everyone jumps in and provides their advice and opinion. This forum is loaded with valuable information-- what a great resource!