Good question!!

Here is what I would do.

Step 1: refinish.

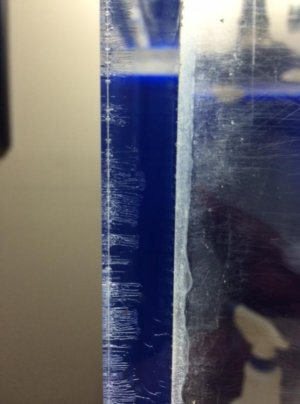

This is easiest to do now. Take vinegar soaked paper towels or cotton cloth (old t-shirt material, or the wipe you can buy at Lowes) and soak off all the coralline/etc.

Then, get yourself a Preppin' Weapon (google it) and some wet/dry sandpaper and have at it. Depending on the scratches, you might need to start with 400 on some but should need more than that. Then work your way through the grades. If you really want to get fancy, rent an air compressor and an air-driven orbital wet/dry sander and do it that way. Remember always sand wet, rinse a lot.

Finish it off with a high-speed polisher with Meguiar's Ultra-cut first, then Swirl-free polish next, using a different pad for each (the magenta one).

After you finish each side, mask it with new paper mask (you can buy these in rolls). This is kind of a PITA but you will be happy you did it.

Step 2: cut & prep

So figure out what you can make, and design the tank using the material you will have available. Rough cut and router edge prep as normal, per info in this thread.

Step 3: build.

What it says.