My thoughts on this:

The corners on the cutouts are very small radius, meaning the stress is going to focus here and it's going to be prone to cracking out here. This is probably the #1 mistake made when doing the euro cutouts

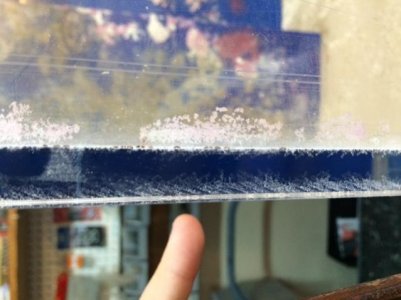

In that 2nd pic, the seam looks like it is starting to fail, either that, or it wasn't very good to begin with. The pattern of air however is not what I normally see with a seam that is coming apart, but rather it looks like the edges were not routed but rather saw cut, because you can literally see the saw cut pattern where the air bubbles or crazing has occurred (hard to tell, low res pic)

Used acrylic tanks are a gamble because what happens is that a tank will settle into the stand that it's on and all it's imperfections. It will adsorb water and expand slightly over the first 4 months. When you take the water out this process reverses somewhat. and the tank can change shape a bit. If you then take that tank and put it on a different stand (even a better one) then the tank can go through another settling process and all of the stress that it was "used to" has now changed, and that could (repeat, could) result in some kind of failure down the line. The advice I typically give with used acrylic tanks is therefore to get the stand that came with the tank, or at least, get a really good look at it and make sure it was done right so that if you build one right, you have a much better chance.

Overall though I would walk away. That seam raises many red flags about the construction of the tank, or the stand that it was on (something has resulted in undue stress somewhere)