Can anyone comment on puckboard as to what it is made from? I want to use it to skin my stand (magnets to hold it) and to fabricate canopies for my LED pendants. Any idea if weld on will weld it together? I don't even know if it is similar or the same as acrylic. It's much cheaper for me though so I would like to give it a try.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acrylic fabrication questions? I can help!

- Thread starter JohnL

- Start date

pico-reefer

New member

not really a acrylic question, but can you bond acrylic to regular sch.40 pvc with weldon 16?

RokleM

Premium Member

not really a acrylic question, but can you bond acrylic to regular sch.40 pvc with weldon 16?

I prefer WO40, but yes 16 will indeed do the trick.

Floyd R Turbo

Either busy or sleeping

IMO, WO 16 will not work well to bond PVC to acrylic. It will bond it, if you do it right, but the bond is easily broken. I don't think it's really made to bond PVC to acrylic. WO 4052 is probably a better choice

pico-reefer

New member

i was looking to put a "viewing window" into the side of a peice of 4" PVC pipe, i would heat the acrylic up and have it bend into the shape of the pvc. the pvc would be 9" tall, and the window would be 3x5"

nlgill13

New member

Im trying to protect my new acrylic tank from scratching.....mostly what i have seen is people saying don't scratch the tank...i do have an idea and wanted to run it pass you all.

Would it be possible to get the outside of the tank clearbra'ed like you would do to the front of your car...The material is strong and very clear (to withstand the punishment of a car at high speeds & clear enough that you can't see it if installed properly).

If anyone has tried this or has any other suggestions let me know

Would it be possible to get the outside of the tank clearbra'ed like you would do to the front of your car...The material is strong and very clear (to withstand the punishment of a car at high speeds & clear enough that you can't see it if installed properly).

If anyone has tried this or has any other suggestions let me know

Floyd R Turbo

Either busy or sleeping

i was looking to put a "viewing window" into the side of a peice of 4" PVC pipe, i would heat the acrylic up and have it bend into the shape of the pvc. the pvc would be 9" tall, and the window would be 3x5"

I suppose that's cheaper that paying $200+ for a 10' clear PVC pipe. I wouldn't allow it to be a pressure/return pipe, just to be on the safe side. But you have the general idea. You can bend acrylic around PVC pipe just by draping it over it and heating it up with a heat gun, keeping the heat even by constantly moving the gun back and forth until it starts draping over it. Could take a while. Then trim off the excess, cut the hole in the pipe, bond it, and clamp it (after a little soak time, not sure how long, but 30 sec should do). I think WO 16 will be your choice for this if you don't have WO 40. You would have to get the 2 pieces to fit together perfectly for 4052 to work I would think, which may or may not be tough.

Anyone know what happened to James / Acrylics? Maybe a much needed vacation?

Floyd R Turbo

Either busy or sleeping

Finished up my router table

And put it to use this week making baffles for a tank-to-sump conversion. Cut up an old busted sump for the baffles. I won't be doing that again. Too much work, but got lots of practice squaring corners and trim routing. Also discovered the dangers of a 3/4" bit running at 26,000 RPM. One piece got caught on my fence (which was a level) as I was feeding it and it took out a gouge and sprayed me with shavings. Had to shut the router off midway through. Happened one other time too when doing a freehand cut, those shavings actually broke my skin in a couple spots. So I won't be doing that again anytime soon. It's a new (proper) fence, a leather apron, and custom templates for me from now on...and no trying anything 'new' unless I've read up on it. I felt pretty stupid.

PS Lemon Pledge Rocks.

And put it to use this week making baffles for a tank-to-sump conversion. Cut up an old busted sump for the baffles. I won't be doing that again. Too much work, but got lots of practice squaring corners and trim routing. Also discovered the dangers of a 3/4" bit running at 26,000 RPM. One piece got caught on my fence (which was a level) as I was feeding it and it took out a gouge and sprayed me with shavings. Had to shut the router off midway through. Happened one other time too when doing a freehand cut, those shavings actually broke my skin in a couple spots. So I won't be doing that again anytime soon. It's a new (proper) fence, a leather apron, and custom templates for me from now on...and no trying anything 'new' unless I've read up on it. I felt pretty stupid.

PS Lemon Pledge Rocks.

Floyd R Turbo

Either busy or sleeping

dodofish

New member

Hello,

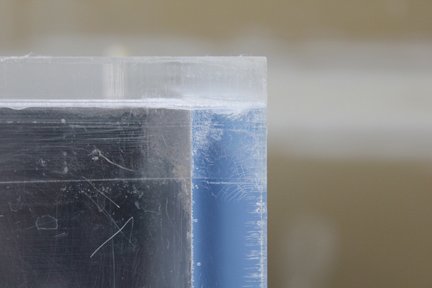

I received this tank and want to know if it is safe. Tank dimensions 72x24x30. I posted a seperate thread the input was that it was not safe but they said I should post the pics in this thread.

Any advise would be much appreciated.

I received this tank and want to know if it is safe. Tank dimensions 72x24x30. I posted a seperate thread the input was that it was not safe but they said I should post the pics in this thread.

Any advise would be much appreciated.

Attachments

Floyd R Turbo

Either busy or sleeping

Hard to see from the pics. If the crazing is in the joint, then the seam is on it's way out. Hard to say how long it would last, and depending on how old & brittle the tank is, how fast it would go when it does go. If the crazing is on the polished edge of the corner, it's a little less to worry about, but it's a sign of stress nonetheless. Might have been flame polished instead of hand polished, which induces stress into the material.

It looks to me like the crazing is both in the joint and on the outside edge - is that correct? I'd say it's a gamble.

It looks to me like the crazing is both in the joint and on the outside edge - is that correct? I'd say it's a gamble.

dahenley

New member

James...

i ordered some cut pieces of clear cast acrylic, and when i recieved it, it was Chemcast GP...

I know by looking back, its def not in your top 3, and you even go as far as saying you wont touch it...

but WAY back, you said that if you take a piece of it and glue it up and test it, it may be useable, but def not as a tank. (im going to build a 3/8 thick 18x18x18 ATO tank with it. )

what are your thoughts..... (i have 3 sheets of 3/8 x 18 x 36 chemcast now...)

Thanks.

i ordered some cut pieces of clear cast acrylic, and when i recieved it, it was Chemcast GP...

I know by looking back, its def not in your top 3, and you even go as far as saying you wont touch it...

but WAY back, you said that if you take a piece of it and glue it up and test it, it may be useable, but def not as a tank. (im going to build a 3/8 thick 18x18x18 ATO tank with it. )

what are your thoughts..... (i have 3 sheets of 3/8 x 18 x 36 chemcast now...)

Thanks.

Floyd R Turbo

Either busy or sleeping

WO3 and WO4 should work for poly to poly for brackets and such. As long as you do not try to make a watertight box. if it needs to support any weight, you might want to test it. I've never worked with poly but WO4's sheet says it will bond poly to poly, but it's kind of a 'jack of all trades' product. there might be something better out there for bonding poly

I came across some "acrylic" or plexi. It is coverd in a white plastic but has no writing on it anywhere, so with out being an acrylic pro is there a way to tell what kind of acrylic it is? Does the cell cast acrylic look different than other kinds or have any other tell tale signs? It is 1/4" material, so if nothing else I may use it for small projects/ brackets instead of the lexan...

Floyd R Turbo

Either busy or sleeping

Plastic masked acrylic is generally extruded. Plexiglas-MC (extruded) usually comes with a paper mask. So does Acrylite FF. It's probably an imported (cheap) extruded. It will probably be fine for small projects, but not for a pressure vessel.

Similar threads

- Replies

- 2

- Views

- 719

- Replies

- 2

- Views

- 298

- Replies

- 12

- Views

- 2K