scubasamdo

New member

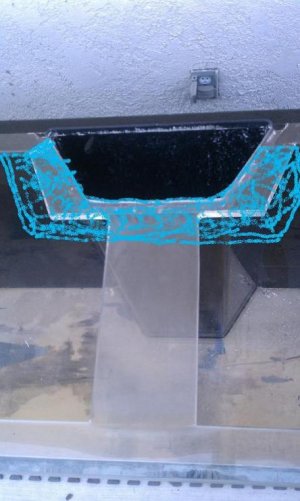

Question about a topbrace crack.

I recently purchased an aprox 5 year old 300+ tank setup. During the move the topcrossbrace was cracked. The tank is 84"L x 36"H x 24"W, it has 1 inch acrylic for the sides and I think the bottom, the top brace is 3/4 inch. There is only one overflow box in the back center with 2 drain and 2 return holes in the bottom. The remainder of the tank appears sound w good joints / structure. It holds water (clamp was used for safety) the max seperation of the crack was just under 1/4 inch. Here are the picts. My ideas to follow but recomendations are sought on this matter. The tank manufacturer is unknown.

Thanks

Sam

I recently purchased an aprox 5 year old 300+ tank setup. During the move the topcrossbrace was cracked. The tank is 84"L x 36"H x 24"W, it has 1 inch acrylic for the sides and I think the bottom, the top brace is 3/4 inch. There is only one overflow box in the back center with 2 drain and 2 return holes in the bottom. The remainder of the tank appears sound w good joints / structure. It holds water (clamp was used for safety) the max seperation of the crack was just under 1/4 inch. Here are the picts. My ideas to follow but recomendations are sought on this matter. The tank manufacturer is unknown.

Thanks

Sam