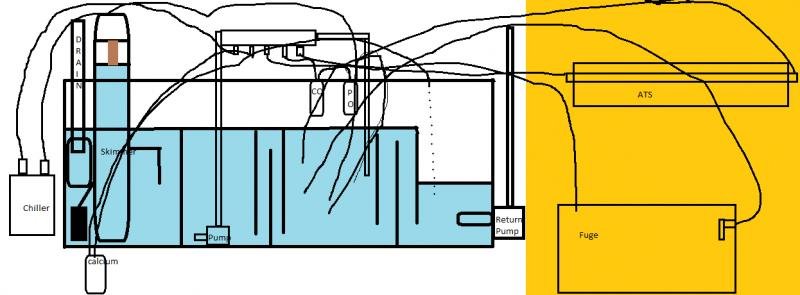

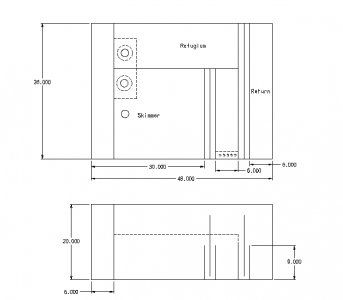

I was reluctant to start this thread since I didn't actually order my tank yet, but here goes! I am planning on a 305 gallon glass tank. The dimensions will be 84" long X 30" deep X 28" high. The tank will be 3 sided starfire with an external overflow and euro bracing. In the past I have had many reef tanks, the last one was an Elos 120xl that I broke down 3 years ago. I sold my tank because my first child was on the way and we lived in a small apartment and needed the space. Since then I moved to a larger house. While renovating my house I put a few things in place for a future tank. I have 4 20 amp breakers wired to my tank and what will be a fish room in my basement using GFI outlets. I also have a water line plumbed to my tank room for a sink along with a floor drain in place for emergencies. I also had a 6" I beam put in under the floor joists I thought the tank would be resting on. The beam is 96" long and is held up by metal posts which are on footings in my basement which is concrete.

So why am I staring this thread right now? Because I need some help. First off there are allot of new equipment and technology that wasn't around 3 years ago when I took a break from this hobby. I have questions regarding some stuff and would love input and recommendations for things. I also have some setup and design things I am not sure about and would really appreciate some guidance and input.

It turns out the I beam installed isn't exactly where I think I want it to be. My house is built of wood. This isn't a new construction house and I have 2 x 9's going across my house (26 feet wide) that rest on a center beam. The joists are spaced 16" apart. The tank will be going against an exterior wall. The depth of the tank is 30". The I beam was placed roughly 40" to 42" away from that same exterior wall. After accounting for sheetrock, insulation and a radiator cover (more on that in a minute) I will be around 12" away from the tip of the wall (where the joists rest on the foundation walls. If the 30" deep tank rests 12" off the wall and comes out to 42" then it's sitting on the tip of where the I beam under it is, at best. Is that going to pose a problem? Is it a big deal that I beam isn't centered under the tank or at least under it at all? I figure the tank filled with water and rock plus the stand and other equipment should weigh approximately 3500 pounds! If there is anyone on here that has experience with structural stuff that can chime in I would greatly appreciate it.

My next question: I am going to get a metal stand that is 44" high. As previously mentioned my sump will be in my basement. The wall I want the tank against has a 6 foot radiator. 4 feet of that radiator will be behind my tank. The radiator including the cover is 24" high. My stand will be made of metal. Do you think the heat coming out of the radiator will have any negative effects on my stand, silicone or glass on tank, pvc or flex spa plumbing lines or cause the water to get hot? I am going to post a picture in a minute. The wainscoting is 42" high my stand will be 44" so the bottom of the tank after plywood and foam should be at like 45" and the top of the radiator cover is 24". It's a water system so it doesn't mist steam like a steam system, but it still heats up (that's what it's there for).

Thanks in advance for your help. We are going to have a sick time building this tank. I am a sick human being and once I get started I won't stop. I will spend money I don't have. I am self-employed so I will often "work from home" and just become totally irresponsible while I build this thing lol! I just can control my-self, I admit it! I am also and equipment junkie. It doesn't take more than "œthat's awesome" for me to make impulse purchases (with money I shouldn't be spending lol) FYI were expecting again and the due date is in 6 weeks right when the tank drama will start!

So why am I staring this thread right now? Because I need some help. First off there are allot of new equipment and technology that wasn't around 3 years ago when I took a break from this hobby. I have questions regarding some stuff and would love input and recommendations for things. I also have some setup and design things I am not sure about and would really appreciate some guidance and input.

It turns out the I beam installed isn't exactly where I think I want it to be. My house is built of wood. This isn't a new construction house and I have 2 x 9's going across my house (26 feet wide) that rest on a center beam. The joists are spaced 16" apart. The tank will be going against an exterior wall. The depth of the tank is 30". The I beam was placed roughly 40" to 42" away from that same exterior wall. After accounting for sheetrock, insulation and a radiator cover (more on that in a minute) I will be around 12" away from the tip of the wall (where the joists rest on the foundation walls. If the 30" deep tank rests 12" off the wall and comes out to 42" then it's sitting on the tip of where the I beam under it is, at best. Is that going to pose a problem? Is it a big deal that I beam isn't centered under the tank or at least under it at all? I figure the tank filled with water and rock plus the stand and other equipment should weigh approximately 3500 pounds! If there is anyone on here that has experience with structural stuff that can chime in I would greatly appreciate it.

My next question: I am going to get a metal stand that is 44" high. As previously mentioned my sump will be in my basement. The wall I want the tank against has a 6 foot radiator. 4 feet of that radiator will be behind my tank. The radiator including the cover is 24" high. My stand will be made of metal. Do you think the heat coming out of the radiator will have any negative effects on my stand, silicone or glass on tank, pvc or flex spa plumbing lines or cause the water to get hot? I am going to post a picture in a minute. The wainscoting is 42" high my stand will be 44" so the bottom of the tank after plywood and foam should be at like 45" and the top of the radiator cover is 24". It's a water system so it doesn't mist steam like a steam system, but it still heats up (that's what it's there for).

Thanks in advance for your help. We are going to have a sick time building this tank. I am a sick human being and once I get started I won't stop. I will spend money I don't have. I am self-employed so I will often "work from home" and just become totally irresponsible while I build this thing lol! I just can control my-self, I admit it! I am also and equipment junkie. It doesn't take more than "œthat's awesome" for me to make impulse purchases (with money I shouldn't be spending lol) FYI were expecting again and the due date is in 6 weeks right when the tank drama will start!