Very nice write up and graphics. One small nitpicky thing: a 10"x10" screen lit by both sides actually has 200 square inches of surface area (both sides).

+1 for Srusso's comment.

Some additional hints:

Flow across screen should be minimum 35 GPH/inch of screen width. of course, you can get away with less, just look at mine at 22 GPH/in, but it's also T5HO and enclosed.

Slot tube should NOT have crosscuts. Slot should be 1/8" wide. Use spray and light blockers if not enclosed in acrylic box so that your lights are protected. Originally, crosscuts were recommended to prevent slot clogging. Eventually it was determined that it makes the flow uneven and actually promotes algae growth into the slot. With no crosscuts, the head pressure on the slot prevents algae from growing into the slot, but may cause sideways spray. Hence spray / light blocker.

For this purpose, find a sheet of black plastic at your local hobby store for $2:

Lights must - MUST - be in close proximity, and must pointed directly at screen, perpendicular if possible. The vast majority of ATS issues are related to incorrect placement of lighting.

After screen is broken in (5 to 6 weeks), you MUST clean every 7 days no matter what. During screen break-in period, cleaning may need to be more frequent depending on nutrient load and type of algae growth.

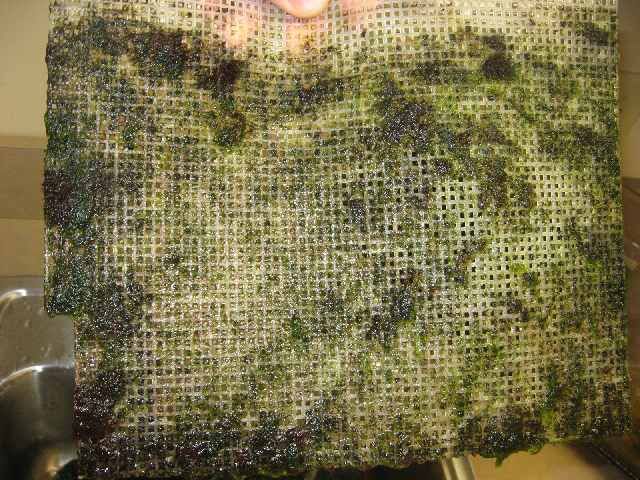

You want green hair algae growth as it does not block light from reaching the lower layers as much as red turf. Plus it cleans off easier. This is a pic of a just-cleaned screen

You can see that the GHA cleans off easily with the backs of your fingernails. The dark spots are the red turf. You need a razor blade to clean that stuff off. Old dump-bucket style scrubbers used this stuff and whoa does it stink bad when it's exposed to the air and your nostrils.

Some hints if you are thinking of adding one of these to your system:

1) Plan it out and do your research. Building a scrubber without thinking about it could put you into the category of "I tried that and it didn't work" because you failed to plan. Don't be that guy. We want you to not be that guy. Or gal. We want you to succeed.

2) Test your overflow rate. This is critical and I cannot overstate the importance. TEST YOUR OVERFLOW RATE. Take a pitcher and record the time it takes to fill it from the overflow inlet into your sump. Do this a dozen or so times and figure out your actual GPH. Don't use your pump rating or even pump rating less head, do it with real conditions. You might be surprised. Design the WIDTH of your screen accordingly, Flow rate / 35 = inches of screen width. Then, tank volume / width = length of screen.

3) Present your design to someone who has built one and see if they catch a potential issue. It's easier to go back to the drawing board than it is to deal with a poor design after it's already running.

4) Look at as many examples as you can and learn from what others have done. There's a huge thread on Reef Sanctuary with hundreds of builds (ignore the hotheads) and of course there's SM's site.

That's all I can think of for now...